Ma PCB a 16-wosanjikiza amapereka zovuta komanso kusinthasintha komwe kumafunikira ndi zida zamakono zamakono. Kupanga mwaluso komanso kusankha njira zodulirana komanso njira zolumikizirana ndi ma interlayer ndizofunikira kwambiri kuti tikwaniritse magwiridwe antchito a board. M'nkhaniyi, tiwona malingaliro, malangizo, ndi njira zabwino zothandizira okonza ndi mainjiniya kupanga ma board oyendera 16-layer odalirika komanso odalirika.

1.Kumvetsetsa Zofunikira za 16 wosanjikiza PCBs Stacking Sequence

1.1 Tanthauzo ndi cholinga cha stacking order

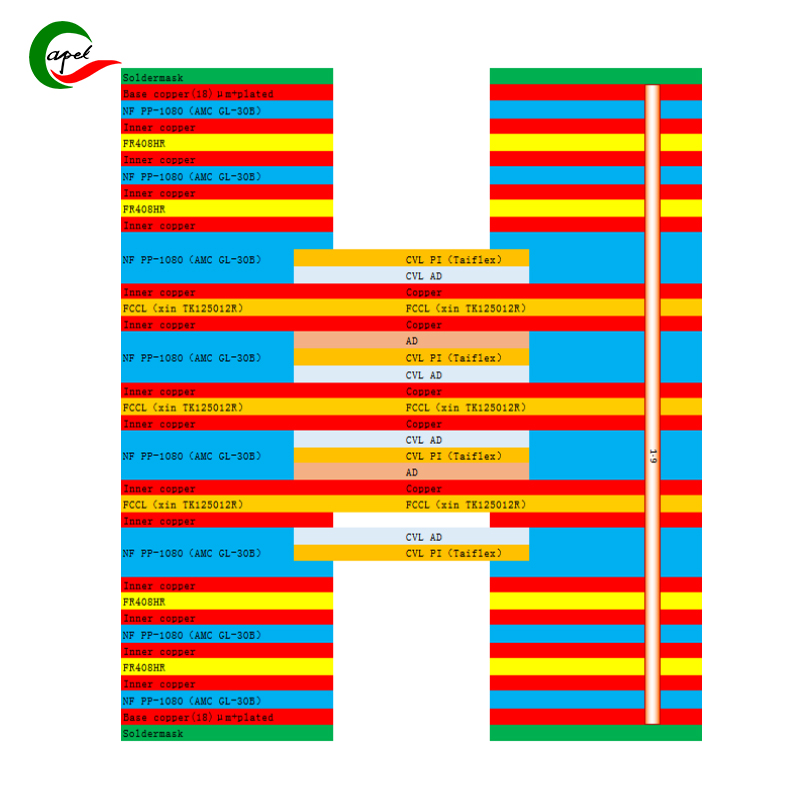

Kutsatizana kwa stacking kumatanthawuza makonzedwe ndi dongosolo limene zipangizo monga mkuwa ndi zigawo zotetezera zimayikidwa pamodzi kuti zipange gulu lozungulira lamagulu ambiri. phula.

Cholinga chachikulu cha mndandanda wa stacking ndikukwaniritsa zofunikira zamagetsi ndi makina a bolodi. Zimagwira ntchito yofunikira pakuzindikira kulephera kwa board board, kukhulupirika kwa ma sign, kugawa mphamvu, kasamalidwe kamafuta, komanso kuthekera kopanga. Mayendedwe a stacking amakhudzanso magwiridwe antchito onse, kudalirika, ndi kupanga kwa bolodi.

1.2 Zinthu zomwe zimakhudza kapangidwe ka stacking: Pali zinthu zingapo zomwe muyenera kuziganizira popanga masanjidwe a stacking a

16-wosanjikiza PCB:

a) Malingaliro amagetsi:Kapangidwe ka ma siginecha, mphamvu, ndi ndege zapansi ziyenera kukonzedwa kuti zitsimikizire kukhulupirika koyenera kwa ma sign, kuwongolera kwa impedance, ndikuchepetsa kusokoneza kwa ma elekitiroma.

b) Kuganizira za kutentha:Kuyika kwa mphamvu ndi ndege zapansi ndi kuphatikizika kwa matenthedwe otenthetsera kumathandizira kutulutsa kutentha bwino ndikusunga kutentha kwabwino kwa gawolo.

c) Zolepheretsa kupanga:Mayendedwe a stacking omwe asankhidwa ayenera kuganizira za kuthekera ndi zofooka za njira yopangira PCB, monga kupezeka kwa zinthu, kuchuluka kwa zigawo, chiŵerengero cha kubowola,ndi kulondola kwa mayendedwe.

d) Kukhathamiritsa Mtengo:Kusankhidwa kwa zipangizo, chiwerengero cha zigawo, ndi zovuta zowonongeka ziyenera kugwirizana ndi bajeti ya polojekiti ndikuwonetsetsa kuti ntchito ndi yodalirika.

1.3 Mitundu yodziwika bwino yamasanjidwe a 16-wosanjikiza board: Pali magawo angapo odziwika bwino a masanjidwe a 16-wosanjikiza.

PCB, kutengera ntchito ankafuna ndi zofunika. Zitsanzo zina zodziwika bwino ndi izi:

a) Symmetric stacking motsatana:Kutsatizana kumeneku kumaphatikizapo kuyika zigawo za chizindikiro molingana pakati pa mphamvu ndi zigawo zapansi kuti zikwaniritse kukhulupirika kwa chizindikiro, kusakanikirana kochepa, ndi kutentha kwapakati.

b) Sequential stacking:Mwanjira iyi, zigawo zazizindikiro zimakhala motsatana pakati pa zigawo za mphamvu ndi pansi. Zimapereka kuwongolera kwakukulu pamasanjidwe osanjikiza ndipo ndizopindulitsa kukwaniritsa zofunikira zamtundu wazizindikiro.

c) Kuphatikizika kwa stacking:Izi zimaphatikizapo kuphatikiza ma symmetric ndi ma sequential stacking. Imalola makonda ndi kukhathamiritsa kwa masanjidwe a magawo ena a bolodi.

d) Kutsatizana kwakusanjika kwa ma Signal:Kutsatizana kumeneku kumayika zigawo zazizindikiro zomveka pafupi ndi ndege yapansi kuti chitetezo chitetezeke bwino komanso kudzipatula.

2.Maganizo Ofunika Kwambiri pa 16 wosanjikiza PCB Stacking Sequence Selection:

2.1 Umphumphu wa chizindikiro ndi kukhulupirika kwamphamvu:

Mndandanda wa stacking umakhudza kwambiri kukhulupirika kwa chizindikiro ndi kukhulupirika kwa mphamvu ya bolodi. Kuyika koyenera kwa chizindikiro ndi ndege zamphamvu / pansi ndikofunikira kuti muchepetse chiwopsezo cha kusokonekera kwa ma siginecha, phokoso, ndi kusokoneza kwamagetsi. Zolinga zazikulu ndi izi:

a) Kuyika kwa chizindikiro:Zigawo zazizindikiro zothamanga kwambiri ziyenera kuyikidwa pafupi ndi ndege yapansi kuti ipereke njira yobwerera yotsika komanso kuchepetsa kulumikizana kwaphokoso. Zigawo za ma siginecha ziyeneranso kuyalidwa mosamala kuti muchepetse kusokonekera kwa ma sign ndi kufananiza kutalika.

b) Kugawa ndege zamphamvu:Mayendedwe a stacking ayenera kuwonetsetsa kuti ndege yamagetsi igawidwe mokwanira kuti ithandizire kukhulupirika kwa mphamvu. Mphamvu zokwanira ndi ndege zapansi ziyenera kuyikidwa mwanzeru kuti zichepetse kutsika kwamagetsi, kutha kwa impedance, ndi kulumikizana kwaphokoso.

c) Decoupling Capacitors:Kuyika bwino kwa ma decoupling capacitor ndikofunikira kuti mutsimikizire kusuntha kwamagetsi kokwanira ndikuchepetsa phokoso lamagetsi. Kutsatizana kwa stacking kuyenera kupereka kuyandikira komanso kuyandikira kwa ma decoupling capacitors ku mphamvu ndi ndege zapansi.

2.2 Kasamalidwe ka kutentha ndi kutaya kutentha:

Kuwongolera bwino kwamafuta ndikofunikira kuti muwonetsetse kudalirika kwa board board ndi magwiridwe antchito. Mayendedwe a stacking ayenera kuganizira za kuyika koyenera kwa mphamvu ndi ndege zapansi, njira zotentha, ndi njira zina zoziziritsira. Zofunikira zofunika ndizo:

a) Kugawa ndege zamagetsi:Kugawa kokwanira kwa mphamvu ndi ndege zapansi pamtunda wonse kumathandizira kuwongolera kutentha kutali ndi zigawo zomveka ndikuwonetsetsa kugawidwa kwa kutentha kofanana pa bolodi.

b) Njira zotentha:Mayendedwe a stacking ayenera kulola kutenthedwa kogwira mtima kudzera pakuyikako kuti athandizire kutulutsa kutentha kuchokera mkati kupita kumalo akunja kapena sinki yotentha. Izi zimathandiza kupewa malo otentha omwe ali m'deralo ndikuwonetsetsa kuti kutentha kumatayika.

c) Kuyika zinthu:Kutengera kwa stacking kuyenera kuganizira makonzedwe ndi kuyandikira kwa zida zotenthetsera kuti zisatenthedwe. Kuyanjanitsa koyenera kwa zigawo ndi njira zoziziritsira monga zotengera kutentha kapena mafani ziyenera kuganiziridwanso.

2.3 Zolepheretsa kupanga ndi kukhathamiritsa mtengo:

Kutsata kwa stacking kuyenera kuganizira zolepheretsa kupanga komanso kukhathamiritsa kwa mtengo, chifukwa zimagwira ntchito yofunika kwambiri pakutheka ndi kukwanitsa kwa bolodi. Zolingalira zikuphatikizapo:

a) Kupezeka kwazinthu:Mndandanda wa stacking womwe wasankhidwa uyenera kugwirizana ndi kupezeka kwa zipangizo komanso kugwirizana kwake ndi njira yosankhidwa ya PCB.

b) Chiwerengero cha zigawo ndi zovuta:Mayendedwe a stacking ayenera kupangidwa mkati mwa zopinga za njira yosankhidwa ya PCB, poganizira zinthu monga kuchuluka kwa zigawo, chiŵerengero cha kubowola, ndi kulondola kwa kulondola.

c) Kukhathamiritsa kwa mtengo:Mayendedwe a stacking ayenera kukhathamiritsa kugwiritsa ntchito zida ndikuchepetsa zovuta zopanga popanda kusokoneza magwiridwe antchito komanso kudalirika. Iyenera kukhala ndi cholinga chochepetsera ndalama zomwe zimagwirizana ndi zinyalala zakuthupi, kuvutikira ndi kusonkhanitsa.

2.4 Kuyanjanitsa kosanjikiza ndi ma sign crosstalk:

Kutsatizana kwa stacking kuyenera kuthana ndi zovuta za masanjidwe osanjikiza ndikuchepetsa ma signal crosstalk omwe angasokoneze kukhulupirika kwa ma sign. Zofunikira zofunika ndizo:

a) Symmetrical stacking:Ma Symmetrical stacking of sign layers pakati pa mphamvu ndi pansi amathandizira kuchepetsa kulumikizana ndikuchepetsa kuphatikizika.

b) Njira ziwiri zosiyana:Mayendedwe a stacking ayenera kulola kuti zigawo zazizindikiro zigwirizane bwino kuti ziziyenda bwino pamasinthidwe othamanga kwambiri. Izi zimathandiza kusunga kukhulupirika kwa chizindikiro ndi kuchepetsa crosstalk.

c) Kupatukana kwa ma Signal:Kutsatizana kwa stacking kuyenera kuganizira za kulekanitsidwa kwa ma analogi ovuta komanso ma siginecha a digito kuti muchepetse kusokoneza ndi kusokoneza.

2.5 Impedans control ndi kuphatikiza kwa RF/microwave:

Pamapulogalamu a RF/microwave, kutsatizana kwa stacking ndikofunikira kuti mukwaniritse kuwongolera koyenera komanso kuphatikiza. Zolinga zazikulu ndi izi:

a) Impedans yoyendetsedwa:Kutsatizana kwa stacking kuyenera kulola kuti pakhale mawonekedwe oyendetsedwa ndi impedance, poganizira zinthu monga kutalika kwa trace, makulidwe a dielectric, ndi masanjidwe. Izi zimatsimikizira kufalikira koyenera kwa ma siginecha ndi kufananiza kwa ma sign a RF/microwave.

b) Kuyika kwa chizindikiro:Ma siginecha a RF/microwave amayenera kuyikidwa mwanzeru pafupi ndi gawo lakunja kuti achepetse kusokonezedwa ndi ma siginecha ena ndikupereka kufalikira kwabwinoko.

c) Kuteteza kwa RF:Njira zodulirana zikuyenera kuphatikiza kuyika koyenera kwa pansi ndi zotchingira kuti zitheke ndikuteteza ma siginecha a RF/microwave kuti asasokonezedwe.

3.Interlayer Connection Njira

3.1 Kudzera m'mabowo, mabowo akhungu ndi maenje okwiriridwa:

Vias chimagwiritsidwa ntchito kusindikizidwa dera bolodi (PCB) kapangidwe monga njira kulumikiza zigawo zosiyanasiyana. Iwo mokhomerera mabowo kudutsa zigawo zonse za PCB ndi yokutidwa kupereka magetsi mosalekeza. Kudzera m'mabowo kupereka mphamvu magetsi kugwirizana ndi zosavuta kupanga ndi kukonza. Komabe, amafunikira kukula kwake kokulirapo, komwe kumatenga malo ofunikira pa PCB ndikuchepetsa zosankha.

Akhungu ndi kukwiriridwa vias ndi njira interlayer kugwirizana njira kuti kupereka ubwino danga magwiritsidwe ndi routing kusinthasintha.

Vis akhungu ndi mokhomerera ku PCB pamwamba ndi kutsirizitsa mu zigawo zamkati popanda kudutsa zigawo zonse. Amalola kulumikizana pakati pa zigawo zoyandikana ndikusiya zigawo zakuya zosakhudzidwa. Izi zimathandiza kugwiritsa ntchito bwino malo a bolodi komanso kuchepetsa chiwerengero cha mabowo obowola. Kukwiriridwa vias, Komano, ndi mabowo kuti kwathunthu anatsekeredwa mkati mwa zigawo zamkati PCB ndipo musapitirire ku zigawo akunja. Amapereka kugwirizana pakati pa zigawo zamkati popanda kukhudza zigawo zakunja. Ma vias okwiriridwa ali ndi mwayi waukulu wopulumutsa malo kuposa ma-mabowo ndi ma akhungu chifukwa satenga malo aliwonse osanjikiza akunja.

Kusankha kudzera mabowo, vias akhungu, ndi vias m'manda zimadalira zofunika zenizeni za mapangidwe PCB. Kudzera m'mabowo nthawi zambiri amagwiritsidwa ntchito m'mapangidwe osavuta kapena pomwe kulimba ndi kukonzanso ndizofunikira kwambiri. M'mapangidwe apamwamba kwambiri pomwe malo ndi chinthu chofunikira kwambiri, monga zida zam'manja, mafoni am'manja, ndi ma laputopu, ma vias akhungu ndi okwiriridwa amakondedwa.

3.2 Micropore ndiHDI luso:

Ma Microvias ndi mabowo ang'onoang'ono (nthawi zambiri osakwana ma microns 150) omwe amapereka kulumikizana kwakukulu kwa interlayer mu ma PCB. Amapereka maubwino ofunikira mu miniaturization, kukhulupirika kwa chizindikiro ndi kusinthasintha kwamayendedwe.

Microvias akhoza kugawidwa mu mitundu iwiri: kudzera-dzenje microvias ndi akhungu microvias. Ma Microvias amapangidwa ndi kubowola mabowo kuchokera pamwamba pa PCB ndikupitilira zigawo zonse. Blind microvias, monga momwe dzinalo likusonyezera, amangowonjezera zigawo zamkati ndipo samalowa m'magulu onse.

High-density interconnect (HDI) ndi ukadaulo womwe umagwiritsa ntchito ma microvias ndi njira zapamwamba zopangira kuti zikwaniritse kachulukidwe wapamwamba komanso magwiridwe antchito. Ukadaulo wa HDI umalola kuyika kwazigawo zing'onozing'ono ndi njira zothina, zomwe zimapangitsa kuti pakhale mawonekedwe ang'onoang'ono komanso kukhulupirika kwazizindikiro. Ukadaulo wa HDI umapereka maubwino angapo kuposa ukadaulo wamba wa PCB pankhani ya miniaturization, kufalitsa ma siginecha bwino, kuchepetsedwa kwa ma siginecha, komanso magwiridwe antchito. Imalola mapangidwe amitundu yambiri okhala ndi ma microvias angapo, potero amafupikitsa kutalika kwa kulumikizana ndikuchepetsa mphamvu ya parasitic ndi inductance.

Ukadaulo wa HDI umathandiziranso kugwiritsa ntchito zida zapamwamba monga ma laminates apamwamba kwambiri komanso zigawo zoonda za dielectric, zomwe ndizofunikira kwambiri pakugwiritsa ntchito RF/microwave. Amapereka kuwongolera bwino kwa impedance, amachepetsa kutayika kwa ma sign ndikuwonetsetsa kufalikira kwamphamvu kodalirika.

3.3 Zida zolumikizira za Interlayer ndi njira:

Kusankhidwa kwa zida zolumikizirana ndi ma interlayer ndikofunikira kwambiri pakuwonetsetsa kuti magetsi akuyenda bwino, kudalirika kwa makina ndi kupanga ma PCB. Zina zomwe zimagwiritsidwa ntchito polumikizira ma interlayer ndi njira ndi:

a) Mkuwa:Mkuwa chimagwiritsidwa ntchito zigawo conductive ndi vias wa PCBs chifukwa madutsidwe ake kwambiri ndi solderability. Nthawi zambiri amakutidwa pa dzenje kuti apereke kulumikizana kodalirika kwamagetsi.

b) Soldering:Njira zowotchera, monga ma wave soldering kapena reflow soldering, nthawi zambiri zimagwiritsidwa ntchito kupanga kulumikizana kwamagetsi pakati pa mabowo pa PCB ndi zigawo zina. Ikani solder phala ku via ndi ntchito kutentha kusungunula solder ndi kupanga odalirika kugwirizana.

c) Electroplating:Njira zopangira ma elekitirodi monga electroless copper plating kapena electrolytic copper amagwiritsidwa ntchito kupangira mbale kuti apititse patsogolo kuwongolera ndikuwonetsetsa kuti magetsi amalumikizana bwino.

d) Kugwirizana:Njira zomangira, monga zomatira zomata kapena thermocompression bonding, zimagwiritsidwa ntchito kulumikiza zida zosanjikiza pamodzi ndikupanga kulumikizana kodalirika.

e) Zida zamagetsi:Kusankha kwa zinthu za dielectric kwa PCB stackup ndikofunikira kwambiri pamalumikizidwe apakati. Ma laminates apamwamba kwambiri monga FR-4 kapena Rogers laminates amagwiritsidwa ntchito nthawi zambiri kuti atsimikizire kukhulupirika kwa chizindikiro ndikuchepetsa kutayika kwa chizindikiro.

3.4 Mapangidwe ndi tanthauzo la magawo osiyanasiyana:

Mapangidwe apakati a PCB stackup amatsimikizira mphamvu zamagetsi ndi zamakina zamalumikizidwe pakati pa zigawo. Zolinga zazikulu pakupanga magawo osiyanasiyana ndi monga:

a) Layer dongosolo:Kukonzekera kwa chizindikiro, mphamvu, ndi ndege zapansi mkati mwa PCB stackup zimakhudza kukhulupirika kwa chizindikiro, kukhulupirika kwa mphamvu, ndi kusokoneza kwa electromagnetic (EMI). Kuyika bwino ndi kuyanjanitsa kwa zigawo zazizindikiro ndi mphamvu ndi ndege zapansi kumathandizira kuchepetsa kulumikizana kwaphokoso ndikuwonetsetsa njira zobwerera zotsika.

b) Kuwongolera kwa Impedans:Mapangidwe a magawo osiyanasiyana akuyenera kuganizira zofunikira zowongolera, makamaka ma siginecha othamanga kwambiri a digito kapena RF/microwave. Izi zimaphatikizapo kusankha koyenera kwa zida za dielectric ndi makulidwe kuti mukwaniritse zomwe mukufuna.

c) Kuwongolera kutentha:Mapangidwe a magawo apakati ayenera kuganizira za kutha kwa kutentha komanso kuwongolera kutentha. Kuyika koyenera kwa magetsi ndi ndege zapansi, njira zotentha, ndi zigawo zomwe zimakhala ndi njira zoziziritsira (monga zozama kutentha) zimathandiza kuthetsa kutentha ndi kusunga kutentha kwabwino.

d) Kudalirika kwamakina:Mapangidwe a gawo ayenera kuganizira kudalirika kwamakina, makamaka pazogwiritsa ntchito zomwe zitha kukhala ndi njinga zamatenthedwe kapena kupsinjika kwamakina. Kusankhidwa koyenera kwa zida, njira zomangira, ndi masinthidwe a stackup zimathandizira kuwonetsetsa kukhulupirika kwadongosolo komanso kukhazikika kwa PCB.

4.Design Guidelines for 16-Layer PCB

4.1 Kugawa ndi kugawa magawo:

Popanga bolodi lozungulira la 16-wosanjikiza, ndikofunikira kugawa mosamala ndikugawa zigawo kuti mukwaniritse bwino ntchito ndi kukhulupirika kwazizindikiro. Nawa malangizo ena ogawa magawo

ndi kugawa:

Dziwani kuchuluka kwa zigawo zazizindikiro zofunika:

Ganizirani zovuta za mapangidwe a dera ndi chiwerengero cha zizindikiro zomwe ziyenera kuyendetsedwa. Perekani zigawo zokwanira zolumikizirana ndi ma siginoloji onse ofunikira, kuwonetsetsa kuti pali malo oyenera olowera ndikupewa kuchulukirachulukira.kusokonekera. Perekani ndege zoyambira ndi zamagetsi:

Perekani zigawo ziwiri zamkati pansi ndi ndege zamagetsi. Ndege yapansi imathandizira kupereka chidziwitso chokhazikika pazizindikiro ndikuchepetsa kusokoneza kwa electromagnetic (EMI). Ndege yamagetsi imapereka njira yochepetsera mphamvu yogawa mphamvu yomwe imathandiza kuchepetsa kutsika kwa magetsi.

Patulani zigawo zomvera bwino:

Kutengera ndikugwiritsa ntchito, pangakhale kofunikira kulekanitsa zigawo zowoneka bwino kapena zothamanga kwambiri kuchokera ku zigawo zaphokoso kapena zamphamvu kwambiri kuti mupewe kusokoneza ndi kuphatikizika. Izi zitha kuchitika poyika malo odzipereka kapena ndege zamagetsi pakati pawo kapena kugwiritsa ntchito zigawo zodzipatula.

Gawani mogawana zigawo zazizindikiro:

Gawani magawo azizindikiro mofanana pagulu lonselo kuti muchepetse kulumikizana pakati pa ma siginolo oyandikana ndikusunga kukhulupirika kwa ma siginecha. Pewani kuyika magulu azizindikiro pafupi ndi mzake m'malo owunjikirana omwewo kuti muchepetse kulumikizana kwapakati.

Lingalirani ma siginecha apamwamba kwambiri:

Ngati mapangidwe anu ali ndi ma siginoloji othamanga kwambiri, ganizirani kuyika magawo a ma frequency apamwamba kwambiri pafupi ndi zigawo zakunja kuti muchepetse zotsatira za mzere wotumizira ndikuchepetsa kuchedwa kufalitsa.

4.2 Mayendedwe ndi ma siginali:

Kapangidwe ka njira ndi kutsata ma siginecha ndikofunikira kuti zitsimikizire kukhulupirika kwa ma siginecha ndikuchepetsa kusokoneza. Nawa maupangiri a masanjidwe ndi ma siginecha pama board ozungulira 16-wosanjikiza:

Gwiritsani ntchito mayendedwe okulirapo pazizindikiro zapamwamba:

Pa ma siginecha omwe amakhala ndi mphamvu zambiri, monga mphamvu ndi zolumikizira pansi, gwiritsani ntchito njira zokulirapo kuti muchepetse kukana ndi kutsika kwamagetsi.

Kufananiza impedance kwa ma siginali othamanga kwambiri:

Kwa ma siginecha othamanga kwambiri, onetsetsani kuti trace impedance ikugwirizana ndi vuto la chingwe chopatsira kuti mupewe kuwunikira komanso kutsika kwa ma sign. Gwiritsani ntchito njira zamapangidwe oyendetsedwa ndi impedance ndikuwerengera molondola m'lifupi mwake.

Chepetsani utali wotsatira ndi ma crossover:

Sungani utali wamfupi momwe mungathere ndikuchepetsa kuchuluka kwa ma crossover kuti muchepetse mphamvu ya parasitic, inductance, ndi kusokoneza. Konzani kakhazikitsidwe kagawo ndikugwiritsa ntchito magawo odzipereka kuti mupewe zovuta zazitali.

Siyanitsani zothamanga kwambiri komanso zotsika:

Siyanitsani zizindikiro zothamanga kwambiri komanso zotsika kuti muchepetse kukhudzidwa kwa phokoso pazidziwitso zothamanga kwambiri. Ikani zizindikiro zothamanga kwambiri pamagulu odzipatulira odzipatulira ndikuwasunga kutali ndi zida zamphamvu kapena zaphokoso.

Gwiritsani ntchito ma awiriawiri osiyana pazizindikiro zothamanga kwambiri:

Kuti muchepetse phokoso ndi kusunga kukhulupirika kwa ma siginecha pazizindikiro zothamanga kwambiri, gwiritsani ntchito njira zosiyanitsira anthu awiriawiri. Sungani zopinga ndi kutalika kwa awiriawiri osiyanitsa kuti mupewe skew ndi crosstalk.

4.3 Ground wosanjikiza ndi gawo la mphamvu yogawa:

Kugawa koyenera kwa ndege zapansi ndi mphamvu ndikofunikira kuti tikwaniritse kukhulupirika kwamphamvu ndikuchepetsa kusokoneza kwamagetsi. Nawa maupangiri okhudza magawo a ndege apansi ndi mphamvu pama board ozungulira 16-wosanjikiza:

Perekani ndege zapansi ndi magetsi odzipereka:

Perekani zigawo ziwiri zamkati za ndege zodzipereka komanso zamphamvu. Izi zimathandiza kuchepetsa malupu apansi, kuchepetsa EMI, ndikupereka njira yobwererera yotsika kwambiri ya zizindikiro zapamwamba.

Olekanitsa ndege za digito ndi analogi:

Ngati mapangidwewo ali ndi magawo a digito ndi analogi, tikulimbikitsidwa kukhala ndi ndege zapansi pagawo lililonse. Izi zimathandizira kuchepetsa kulumikizana kwa phokoso pakati pa magawo a digito ndi analogi ndikuwongolera kukhulupirika kwa ma siginecha.

Ikani ndege zapansi ndi magetsi pafupi ndi ndege zowonetsera:

Ikani ndege zapansi ndi magetsi pafupi ndi ndege zowonetsera zomwe amadya kuti achepetse malo ozungulira ndikuchepetsa phokoso.

Gwiritsani ntchito maulendo angapo pandege zamphamvu:

Gwiritsani ntchito ma vias angapo kuti mulumikizane ndi ndege zamagetsi kuti mugawane mphamvu ndikuchepetsa mphamvu ya ndege. Izi zimathandizira kuchepetsa kutsika kwamagetsi ndikuwongolera kukhulupirika kwamagetsi.

Pewani makosi opapatiza mundege zamphamvu:

Pewani makosi opapatiza mundege zamphamvu chifukwa zitha kuyambitsa kuchulukana komwe kukuchitika ndikuwonjezera kukana, zomwe zimapangitsa kutsika kwamagetsi ndi kulephera kwa ndege zamagetsi. Gwiritsani ntchito kulumikizana mwamphamvu pakati pa madera osiyanasiyana a ndege yamagetsi.

4.4 Thermal pad ndikuyika:

Kuyika koyenera kwa ziwiya zotentha ndi ma vias ndizofunikira kwambiri kuti zithetse kutentha ndikupewa kuti zigawo zisatenthedwe. Nawa malangizo ena a pad matenthedwe komanso kuyika pama board ozungulira 16-wosanjikiza:

Ikani pad yotentha pansi pazigawo zotulutsa kutentha:

Dziwani chigawo chotulutsa kutentha (monga chokulitsa mphamvu kapena IC yamphamvu kwambiri) ndikuyika choyatsira chotenthetsera pansi pake. Mapiritsi otenthetserawa amapereka njira yowotcha yachindunji yosamutsira kutentha kumalo otentha amkati.

Gwiritsani ntchito njira zingapo zotenthetsera kutentha:

Gwiritsani ntchito vias angapo matenthedwe kulumikiza wosanjikiza matenthedwe ndi wosanjikiza akunja kupereka imayenera kutentha dissipation. Vias awa akhoza kuikidwa mu ndondomeko zazambiri padziko matenthedwe PAD kukwaniritsa ngakhale kutentha kugawa.

Ganizirani za kutentha kwa kutentha ndi kusanjika kwa zigawo:

Pamene akukonzekera vias matenthedwe, ganizirani matenthedwe impedance wa zinthu bolodi ndi wosanjikiza stackup.Optimize kudzera kukula ndi katayanitsidwe kuchepetsa kukana matenthedwe ndi kukulitsa kutentha dissipation.

4.5 Kuyika Kwachigawo ndi Kukhulupirika kwa Chizindikiro:

Kuyika kwachigawo koyenera ndikofunikira kuti zisungidwe zazizindikiro ndi kuchepetsa kusokoneza. Nawa maupangiri oyika zigawo pa bolodi la magawo 16:

Zogwirizana ndi gulu:

Magawo okhudzana ndi gulu omwe ali mbali ya kagawo kakang'ono kapena kamene kali ndi mphamvu zamagetsi. Izi zimachepetsa kutalika kwa kutsata ndikuchepetsa kutsika kwa ma sign.

Sungani zinthu zothamanga kwambiri pafupi:

Ikani zigawo zothamanga kwambiri, monga ma oscillator apamwamba kwambiri kapena ma microcontrollers, pafupi ndi wina ndi mzake kuti muchepetse kutalika kwa kufufuza ndikuwonetsetsa kukhulupirika kwa chizindikiro.

Chepetsani kutalika kwa zizindikiro zofunika kwambiri:

Chepetsani kutalika kwa zizindikiro zofunikira kuti muchepetse kuchedwa kufalitsa ndi kuchepetsa zizindikiro. Ikani zigawo izi pafupi kwambiri.

Patulani zigawo zokhudzidwa:

Zigawo zosiyanitsa zomva phokoso, monga zida za analogi kapena masensa otsika, kuchokera ku zida zamphamvu kwambiri kapena zaphokoso kuti muchepetse kusokoneza ndi kusunga kukhulupirika kwa chizindikiro.

Ganizirani za decoupling capacitors:

Ikani ma decoupling capacitor pafupi momwe mungathere ndi mapini amagetsi a gawo lililonse kuti apereke mphamvu zoyera ndikuchepetsa kusinthasintha kwamagetsi. Ma capacitor awa amathandizira kukhazikika kwamagetsi ndikuchepetsa kulumikizana kwaphokoso.

5.Simulation and Analysis Tools for Stack-Up Design

5.1 3D modelling ndi kayeseleledwe mapulogalamu:

3D modelling ndi kayeseleledwe mapulogalamu ndi chida chofunika kwambiri stackup chifukwa amalola okonza kupanga zoimira pafupifupi PCB stackups. Pulogalamuyi imatha kuwona zigawo, zigawo, ndi machitidwe awo akuthupi. Potengera stackup, opanga amatha kuzindikira zomwe zingachitike monga ma signal crosstalk, EMI, ndi zovuta zamakina. Zimathandizanso kutsimikizira kakonzedwe ka zigawo ndi kukhathamiritsa mapangidwe onse a PCB.

5.2 Zida zowunikira kukhulupirika kwa ma Signal:

Zida zowunikira kukhulupirika kwa ma Signal ndizofunikira pakuwunika ndikuwongolera magwiridwe antchito amagetsi a PCB stackups. Zida izi zimagwiritsa ntchito masamu masamu kuti ayese ndi kusanthula machitidwe azizindikiro, kuphatikiza kuwongolera kwa impedance, zowunikira, komanso kulumikizana kwaphokoso. Pochita kayeseleledwe ndi kusanthula, opanga amatha kuzindikira zovuta zomwe zingayambitse kukhulupirika kwa ma siginecha koyambirira kwa kapangidwe kake ndikupanga kusintha kofunikira kuti zitsimikizire kutumizidwa kwa ma siginecha odalirika.

5.3 Zida zowunikira kutentha:

Zida zowunikira matenthedwe zimagwira ntchito yofunika kwambiri pakupanga masanjidwe mwa kusanthula ndikuwongolera kasamalidwe kamafuta a PCB. Zida izi zimatengera kutayika kwa kutentha ndi kugawa kutentha mkati mwa gawo lililonse la stack. Mwa kuyerekezera molondola mphamvu zowonongeka ndi njira zotumizira kutentha, okonza amatha kuzindikira malo otentha, kukhathamiritsa kuyika kwa zigawo zamkuwa ndi ma vias otentha, ndikuonetsetsa kuti kuziziritsa koyenera kwa zigawo zofunika kwambiri.

5.4 Mapangidwe akupanga:

Kupanga kwa kupanga ndi gawo lofunikira pakupanga ma stackup. Pali mitundu yosiyanasiyana ya mapulogalamu omwe alipo omwe angathandize kuonetsetsa kuti zosankhidwazo zikhoza kupangidwa bwino. Zida zimenezi zimapereka ndemanga pa kuthekera kokwaniritsa zosungira zomwe mukufuna, poganizira zinthu monga kupezeka kwa zinthu, makulidwe a wosanjikiza, njira yopangira, ndi mtengo wopangira. Amathandizira opanga kupanga zisankho zodziwika bwino kuti azitha kusungitsa zinthu kuti achepetse kupanga, kuchepetsa chiwopsezo cha kuchedwa, ndikuwonjezera zokolola.

6.Step-by-Step Design Njira ya 16-Layer PCBs

6.1 Zofunikira zoyambira:

Mu sitepe iyi, sonkhanitsani zofunika zonse zofunika 16-wosanjikiza PCB mapangidwe. Mvetsetsani magwiridwe antchito a PCB, magwiridwe antchito amagetsi ofunikira, zopinga zamakina, ndi malangizo aliwonse opangira kapena miyezo yomwe ikuyenera kutsatiridwa.

6.2 Kugawika kwa zigawo ndi makonzedwe:

Malinga ndi zofunikira, kugawa zigawo pa PCB ndi kudziwa makonzedwe awo. Ganizirani zinthu monga kukhulupirika kwa siginecha, malingaliro amafuta, ndi zopinga zamakina. Zigawo zamagulu potengera mawonekedwe amagetsi ndikuziyika mwanzeru pa bolodi kuti muchepetse kusokoneza komanso kukhathamiritsa kuyenda kwa chizindikiro.

6.3 Mapangidwe owukira ndi kugawa magawo:

Tsimikizirani kapangidwe kake ka 16-wosanjikiza PCB. Ganizirani zinthu monga dielectric constant, thermal conductivity, ndi mtengo wosankha zinthu zoyenera. Perekani chizindikiro, mphamvu, ndi ndege pansi malinga ndi zofunikira zamagetsi. Ikani ndege zapansi ndi mphamvu zofananira kuti muwonetsetse kuti zili bwino ndikuwongolera kukhulupirika kwa chizindikiro.

6.4 Kuwongolera ma Signal ndikuwongolera njira:

Mu sitepe iyi, zizindikiro zimayendetsedwa pakati pa zigawo kuti zitsimikizire kuwongolera koyenera, kukhulupirika kwa ma siginecha, ndikuchepetsa ma signal crosstalk. Konzani njira kuti muchepetse kutalika kwa ma sigino ofunikira, pewani kuwoloka mayendedwe owoneka bwino, ndikusunga kusiyana pakati pa ma siginecha othamanga kwambiri ndi otsika. Gwiritsani ntchito mawiri awiri osiyana ndi njira zowongolera zowongolera ngati pakufunika.

6.5 Kulumikizana kwa Interlayer ndikuyika:

Konzani kuyika kwa ma vias olumikizira pakati pa zigawo. Dziwani zoyenera kudzera pamtundu, monga pobowo kapena bowo, kutengera masinthidwe osanjikiza ndi kulumikizana kwazinthu. Konzani pogwiritsa ntchito masanjidwe kuti muchepetse kuwunikira kwa ma siginecha, kuletsa kusokoneza, ndikusunga ngakhale kugawa pa PCB.

6.6 Kutsimikizira komaliza ndi kayeseleledwe:

Asanayambe kupanga, kutsimikizira komaliza ndi kuyerekezera kumachitika. Gwiritsani ntchito zida zoyeserera kusanthula mapangidwe a PCB a kukhulupirika kwa siginecha, kukhulupirika kwamphamvu, machitidwe amatenthedwe, ndi kupangidwa. Tsimikizirani kapangidwe kake motsutsana ndi zofunikira zoyambirira ndikusintha kofunikira kuti muwongolere magwiridwe antchito ndikuwonetsetsa kuti zapangidwa.

Gwirizanani ndikulankhulana ndi ena omwe akukhudzidwa nawo monga mainjiniya amagetsi, mainjiniya amakina, ndi magulu opanga nthawi yonse yopangira kuti zitsimikizire kuti zonse zomwe zikufunika zikukwaniritsidwa komanso zovuta zomwe zingathe kuthetsedwa. Onetsetsani nthawi zonse ndikubwereza mapangidwe kuti muphatikizepo ndemanga ndi kusintha.

7.Industry Best Practices and Case Studies

7.1 Milandu yopambana ya mapangidwe a 16-wosanjikiza PCB:

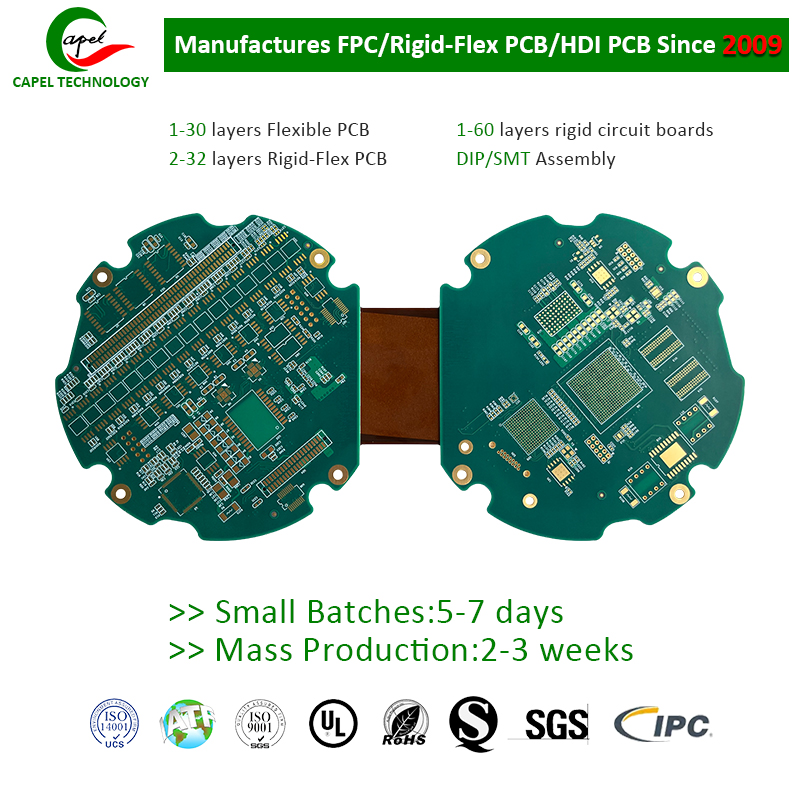

Phunziro 1:Shenzhen Capel Technology Co., Ltd. adapanga bwino PCB yosanjikiza 16 yokhala ndi zida zothamanga kwambiri. Poganizira mosamala za kukhulupirika kwa ma sign ndi kugawa mphamvu, amakwaniritsa magwiridwe antchito apamwamba ndikuchepetsa kusokoneza kwa ma elekitiroma. Chinsinsi cha kupambana kwawo ndikukonza kokwanira bwino kokwanira pogwiritsa ntchito ukadaulo wowongolera wa impedance.

Phunziro 2:Shenzhen Capel Technology Co., Ltd. adapanga PCB yamitundu 16 ya chipangizo chamankhwala chovuta. Pogwiritsa ntchito zida zophatikizira pamwamba ndi pobowo, adapanga mapangidwe ang'onoang'ono koma amphamvu. Kuyika mosamala zigawo ndi njira yabwino kumatsimikizira kukhulupirika kwa chizindikiro ndi kudalirika.

7.2 Phunzirani ku zolephera ndikupewa mbuna:

Phunziro 1:Ena opanga pcb anakumana nkhani kukhulupirika chizindikiro mu 16-wosanjikiza PCB kapangidwe zipangizo kulankhulana. Zifukwa zolephereka zinali zosakwanira kulingalira za kulamulira kwa impedance ndi kusowa kogawa bwino kwa ndege zapansi. Phunziro lomwe laphunziridwa ndikusanthula mosamalitsa zofunikira za kukhulupirika kwa ma siginecha ndikukhazikitsa malangizo okhwima owongolera a impedance.

Phunziro 2:Ena opanga pcb anakumana ndi zovuta kupanga ndi 16-wosanjikiza PCB chifukwa kapangidwe zovuta. Kugwiritsidwa ntchito mopitirira muyeso kwa ma vias akhungu ndi zigawo zodzaza kwambiri kumabweretsa zovuta zopanga ndi zosonkhanitsa. Phunziro lomwe mwaphunzira ndikulinganiza pakati pa zovuta zamapangidwe ndi kupangika potengera kuthekera kwa wopanga PCB wosankhidwa.

Kupewa misampha ndi misampha pamapangidwe a PCB-wosanjikiza 16, ndikofunikira ku:

a.Kumvetsetsa bwino zofunikira ndi zopinga za mapangidwe.

b.Zosanjikiza zomwe zimakulitsa kukhulupirika kwa chizindikiro ndi kugawa mphamvu. c.Gawirani mosamala ndikukonza zigawo kuti muwongolere magwiridwe antchito ndikupangitsa kupanga kukhala kosavuta.

d.Kuwonetsetsa kuti njira zoyendetsera bwino, monga kuwongolera zolepheretsa komanso kupewa kugwiritsa ntchito kwambiri njira zakhungu.

e.Gwirizanani ndikulankhulana bwino ndi onse omwe akukhudzidwa nawo pakupanga mapangidwe, kuphatikizapo akatswiri opanga magetsi ndi makina ndi magulu opanga.

f.Chitani chitsimikiziro chokwanira cha kapangidwe kake ndikuyerekeza kuti muzindikire ndikuwongolera zomwe zingachitike musanapange.

Nthawi yotumiza: Sep-26-2023

Kubwerera