Magalimoto osindikizira amagetsi osindikizira (PCBs) amagwira ntchito yofunika kwambiri pamagalimoto apamwamba masiku ano. Kuyambira pakuwongolera kachitidwe ka injini ndi zowonetsera za infotainment mpaka kuyang'anira chitetezo ndi kuthekera koyendetsa galimoto, ma PCBwa amafunikira mapangidwe osamala ndi njira zopangira kuti zitsimikizire kuti zikuyenda bwino komanso kudalirika.M'nkhaniyi, tikhala tikuyang'ana paulendo wovuta wa PCB zamagalimoto zamagalimoto, ndikuwunika masitepe ofunikira kuyambira poyambira mapangidwe mpaka kupanga.

1.Kumvetsetsa zamagalimoto zamagetsi PCB:

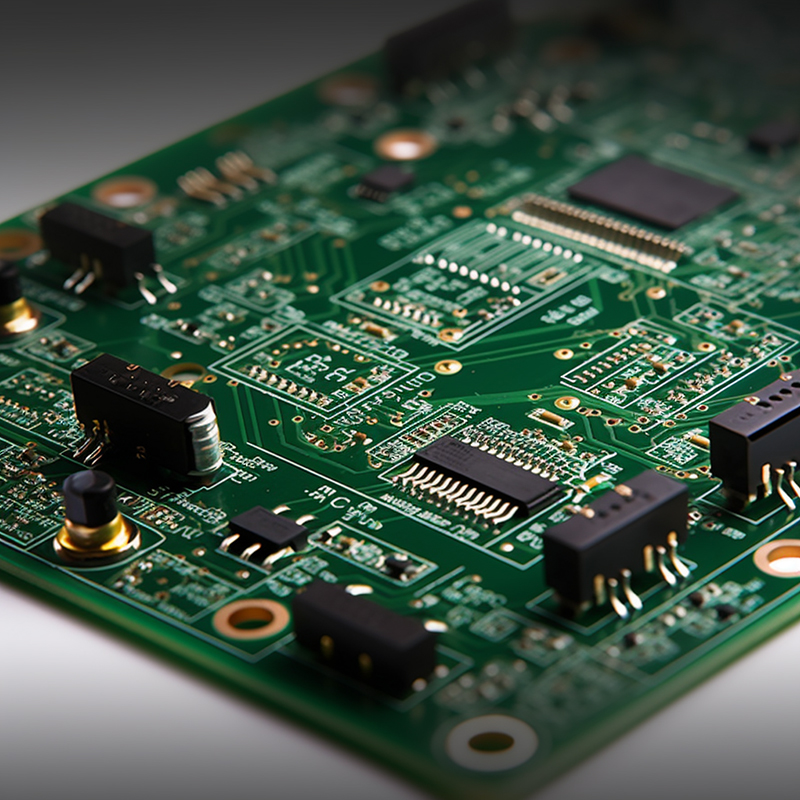

Zamagetsi zamagetsi PCB kapena bolodi losindikizidwa ndi gawo lofunikira pamagalimoto amakono. Iwo ali ndi udindo wopereka maulumikizidwe amagetsi ndi kuthandizira machitidwe osiyanasiyana amagetsi m'galimoto, monga mayunitsi oyendetsa injini, machitidwe a infotainment, masensa, etc.A mbali yofunika kwambiri ya PCB zamagalimoto zamagetsi ndi kuthekera kwawo kupirira malo ovuta a magalimoto. Magalimoto amatha kusintha kwambiri kutentha, kugwedezeka komanso phokoso lamagetsi. Choncho, ma PCBwa ayenera kukhala olimba kwambiri komanso odalirika kuti awonetsetse ntchito yabwino komanso chitetezo. Ma PCB amagetsi amagalimoto nthawi zambiri amapangidwa pogwiritsa ntchito mapulogalamu apadera omwe amalola mainjiniya kupanga masanjidwe omwe amakwaniritsa zofunikira zamakampani amagalimoto. Zofunikira izi zikuphatikizapo zinthu monga kukula, kulemera, kugwiritsa ntchito mphamvu, komanso kugwirizanitsa magetsi ndi zigawo zina. Njira yopangira ma PCB amagetsi amagalimoto imaphatikizapo njira zingapo. Mapangidwe a PCB adapangidwa koyamba komanso mofanizira ndikuyesedwa kuti atsimikizire kuti kapangidwe kake kakukwaniritsa zofunikira. Mapangidwewo amasamutsidwa ku PCB yakuthupi pogwiritsa ntchito njira monga etching kapena kuyika zinthu zoyendetsera pagawo la PCB. Poganizira zovuta za PCB zamagalimoto zamagetsi, zida zowonjezera monga ma resistors, capacitors, ndi mabwalo ophatikizika nthawi zambiri amayikidwa pa PCB kuti amalize kuzungulira kwamagetsi. Zigawo izi nthawi zambiri zimayikidwa pamwamba pa PCB pogwiritsa ntchito makina oyika okha. Chisamaliro chapadera chimaperekedwa ku njira yowotcherera kuti zitsimikizire kulumikizana koyenera komanso kukhazikika. Poganizira kufunikira kwa makina amagetsi apagalimoto, kuwongolera bwino ndikofunikira kwambiri pamakampani amagalimoto. Chifukwa chake, ma PCB apamagetsi apagalimoto amayesedwa mozama ndikuwunika kuti awonetsetse kuti akukwaniritsa zofunikira. Izi zikuphatikiza kuyesa kwamagetsi, kuyendetsa njinga zotentha, kuyesa kugwedezeka komanso kuyesa zachilengedwe kuti zitsimikizire kudalirika kwa PCB komanso kulimba pansi pamikhalidwe yosiyanasiyana.

2.Automotive electronic PCB design ndondomeko:

Kapangidwe ka makina amagetsi a PCB kumaphatikizapo njira zingapo zofunika kuti zitsimikizire kudalirika, magwiridwe antchito, ndi magwiridwe antchito a chinthu chomaliza.

2.1 Mapangidwe a dongosolo: Gawo loyamba pakupanga mapangidwe ndi mapangidwe apangidwe.Mu sitepe iyi, mainjiniya amatanthauzira kugwirizana kwa magetsi pakati pa zigawo za munthu payekha malinga ndi magwiridwe antchito a PCB. Izi zikuphatikizapo kupanga chithunzi chojambula chomwe chimayimira dera la PCB, kuphatikizapo malumikizidwe, zigawo, ndi maubwenzi awo. Munthawi imeneyi, mainjiniya amalingalira zinthu monga mphamvu zamagetsi, njira zolumikizirana, komanso kuyanjana ndi machitidwe ena mgalimoto.

2.2 Mapangidwe a masanjidwe a PCB: Chimangidwecho chikamalizidwa, kamangidwe kake kamalowa mu gawo la mapangidwe a PCB.Mu sitepe iyi, mainjiniya amasintha schematic kukhala mawonekedwe a PCB. Izi zikuphatikizapo kudziwa kukula, mawonekedwe, ndi malo a zigawo pa bolodi la dera, komanso njira ya magetsi. Mapangidwe a masanjidwe amayenera kuganizira zinthu monga kukhulupirika kwa ma sign, kasamalidwe ka matenthedwe, kusokoneza ma elekitiroleti (EMI), ndi kupanga. Chisamaliro chapadera chimaperekedwa pakuyika kwa zigawo kuti ziwongolere kayendedwe ka ma sign ndi kuchepetsa phokoso.

2.3 Kusankha ndi kuyika zinthu: Pambuyo pomaliza kusanja kwa PCB, mainjiniya amapitilira kusankha ndi kuyika zinthu.Izi zikuphatikizapo kusankha zigawo zoyenera malinga ndi zofunikira monga ntchito, kugwiritsa ntchito mphamvu, kupezeka ndi mtengo. Zinthu monga zida zamagalimoto, kuchuluka kwa kutentha ndi kulekerera kwa vibration ndizofunikira pakusankha. Zigawozo zimayikidwa pa PCB molingana ndi mapazi awo ndi malo omwe amatsimikiziridwa panthawi ya mapangidwe apangidwe. Kuyika koyenera ndi kuyika kwa zigawo ndizofunikira kwambiri kuti zitsimikizidwe kuti zimasonkhanitsidwa bwino komanso zikuyenda bwino.

2.4 Kusanthula umphumphu wa chizindikiro: Kusanthula kukhulupirika kwa chizindikiro ndi sitepe yofunikira pamapangidwe a PCB zamagetsi zamagetsi.Zimaphatikizapo kuwunika mtundu ndi kudalirika kwa ma siginecha akamafalikira kudzera mu PCB. Kusanthula uku kumathandizira kuzindikira zovuta zomwe zingachitike monga kuchepetsedwa kwa ma signal, crosstalk, reflection, ndi kusokoneza phokoso. Zida zosiyanasiyana zofananira ndi kusanthula zimagwiritsidwa ntchito kutsimikizira kapangidwe kake ndikuwongolera masanjidwe kuti zitsimikizire kukhulupirika kwa chizindikiro. Opanga amayang'ana kwambiri zinthu monga kutalika kwa trace, kufananiza kwa impedance, kukhulupirika kwamphamvu, ndi njira zowongolera zowongolera kuti zitsimikizire kufalitsa kolondola komanso kopanda phokoso.

Kusanthula kwa kukhulupirika kwa ma Signal kumaganiziranso ma siginecha othamanga kwambiri komanso malo ofunikira mabasi omwe amapezeka pamakina apamagetsi apagalimoto. Monga matekinoloje apamwamba monga Ethernet, CAN ndi FlexRay akugwiritsidwa ntchito kwambiri m'magalimoto, kusunga kukhulupirika kwa chizindikiro kumakhala kovuta komanso kofunika.

3.Automotive electronic PCB kupanga ndondomeko:

3.1 Kusankha kwazinthu: Kusankha kwazinthu zamagetsi zagalimoto za PCB ndikofunikira kuti zitsimikizire kulimba, kudalirika komanso magwiridwe antchito.Zida zomwe zimagwiritsidwa ntchito ziyenera kupirira zovuta zachilengedwe zomwe zimakumana nazo pamagalimoto, kuphatikiza kusintha kwa kutentha, kugwedezeka, chinyezi komanso kuwonekera kwamankhwala. Zida zomwe zimagwiritsidwa ntchito nthawi zambiri pama PCB amagetsi apagalimoto zimaphatikizapo FR-4 (Flame Retardant-4) epoxy-based laminate, yomwe imakhala ndi magetsi abwino, mphamvu zamakina komanso kukana kutentha kwambiri. Ma laminates otentha kwambiri monga polyimide amagwiritsidwanso ntchito pazinthu zomwe zimafuna kusinthasintha kwakukulu kwa kutentha. Kusankha kwazinthu kuyeneranso kuganizira zofunikira za dera logwiritsira ntchito, monga ma siginoni othamanga kwambiri kapena zamagetsi zamagetsi.

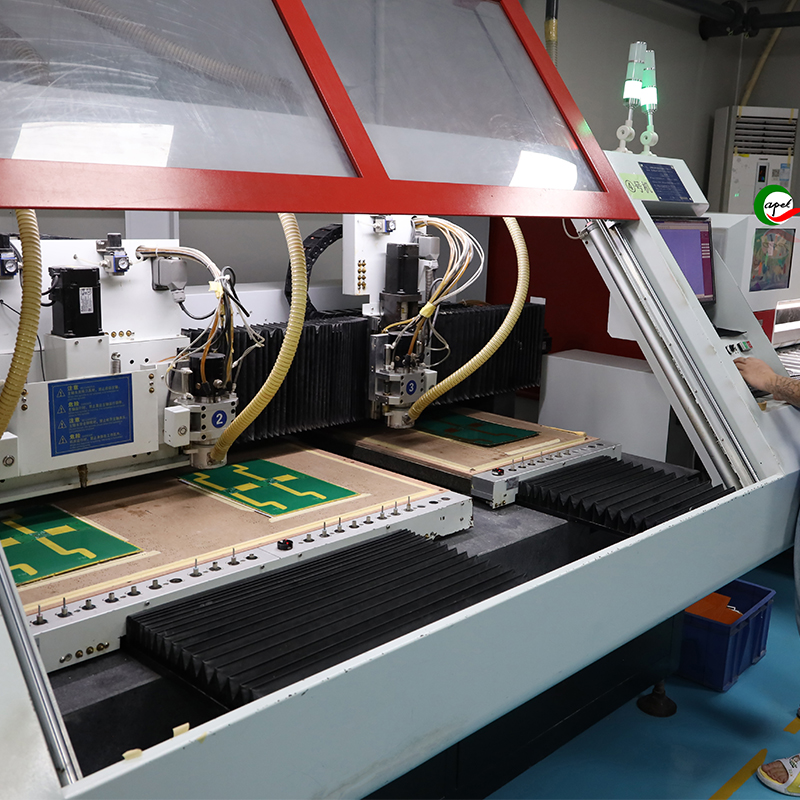

3.2 Ukadaulo wopangira ma PCB: Ukadaulo wopangira PCB umaphatikizapo njira zingapo zomwe zimasinthira mapangidwe kukhala ma board osindikizidwa.Njira yopangira zinthu imakhala ndi izi:

a) Design Transfer:Mapangidwe a PCB amasamutsidwa ku pulogalamu yodzipatulira yomwe imapanga mafayilo ofunikira kuti apange.

b) Panelization:Kuphatikiza mapangidwe angapo a PCB kukhala gulu limodzi kuti mukwaniritse bwino zopanga.

c) Kufotokozera:Valani zosanjikiza za zinthu zowoneka bwino pagawo, ndipo gwiritsani ntchito fayilo yojambula kuti muwonetse mawonekedwe ofunikira pagawo lokutidwa.

d) Kusintha:Mankhwala etching madera poyera gulu kuchotsa mkuwa zapathengo, kusiya ankafuna dera kuda.

e) Kubowola:Kubowola mabowo gulu kuti agwirizane chigawo amatsogolera ndi vias kwa interconnection pakati pa zigawo zosiyanasiyana za PCB.

f) Electroplating:Wowonda wosanjikiza wamkuwa ndi electroplated pa gulu kumapangitsanso madutsidwe wa kuda dera ndi kupereka pamwamba yosalala njira wotsatira.

g) Kugwiritsa ntchito Mask a Solder:Ikani chigoba cha solder kuti muteteze mikwingwirima yamkuwa ku okosijeni ndikupatsanso kutsekeka pakati pa mayendedwe oyandikana nawo. Chigoba cha Solder chimathandizanso kuti pakhale kusiyana koonekera bwino pakati pa zigawo zosiyanasiyana ndi mayendedwe.

h) Kusindikiza pazithunzi:Gwiritsani ntchito njira yosindikizira pazenera kuti musindikize mayina azinthu, ma logo ndi zidziwitso zina zofunika pa PCB.

3.3 Konzani zosanjikiza zamkuwa: Musanapange dera logwiritsira ntchito, zigawo zamkuwa pa PCB ziyenera kukonzekera.Izi zimaphatikizapo kuyeretsa pamwamba pa mkuwa kuchotsa dothi, ma oxides kapena zonyansa. Njira yoyeretsera imathandizira kumamatira kwa zinthu zowoneka bwino zomwe zimagwiritsidwa ntchito pojambula. Njira zosiyanasiyana zoyeretsera zingagwiritsidwe ntchito, kuphatikizapo kuchapa ndi makina, kuyeretsa mankhwala, ndi kuyeretsa madzi a m'magazi.

3.4 Dera logwiritsira ntchito: Zigawo zamkuwa zikakonzedwa, gawo lothandizira litha kupangidwa pa PCB.Izi zimaphatikizapo kugwiritsa ntchito njira yojambulira kusamutsa njira yomwe mukufuna kupita ku PCB. Fayilo yojambula yopangidwa ndi mapangidwe a PCB imagwiritsidwa ntchito ngati chisonyezero chowonetsera zithunzi za PCB ku kuwala kwa UV. Njirayi imaumitsa madera owonekera, kupanga maulendo oyendayenda ofunikira ndi mapepala.

3.5 PCB etching ndi kubowola: Mukapanga dera logwiritsira ntchito, gwiritsani ntchito mankhwala kuti muchotse mkuwa wochulukirapo.Zinthu za photosensitive zimagwira ntchito ngati chigoba, kuteteza mayendedwe ofunikira kuti asamangidwe. Kenako pakubwera pobowola ndondomeko kupanga mabowo kwa chigawo amatsogolera ndi vias mu PCB. Mabowo amabowoledwa pogwiritsa ntchito zida zolondola ndipo malo ake amatsimikiziridwa kutengera kapangidwe ka PCB.

3.6 Plating ndi solder chigoba ntchito: Pambuyo etching ndi kubowola ndondomeko yatha, PCB ndi yokutidwa kuti kumapangitsanso madutsidwe wa mayendedwe dera.Mbale wochepa thupi wosanjikiza wamkuwa pa poyera mkuwa pamwamba. Njira yopangira iyi imathandizira kutsimikizira kulumikizidwa kwamagetsi odalirika ndikuwonjezera kulimba kwa PCB. Pambuyo plating, wosanjikiza chigoba solder ntchito kwa PCB. Chigoba cha solder chimapereka chitetezo komanso chimateteza mikwingwirima yamkuwa ku okosijeni. Nthawi zambiri amagwiritsidwa ntchito ndi kusindikiza pazenera, ndipo malo omwe zigawozo zimayikidwa zimasiyidwa kuti zitheke.

3.7 PCB kuyezetsa ndi kuyendera: sitepe yomaliza pakupanga ndondomeko ndi PCB kuyezetsa ndi kuyendera.Izi zimaphatikizapo kuyang'ana magwiridwe antchito ndi mtundu wa PCB. Mayesero osiyanasiyana monga kuyesa kupitiliza, kuyesa kukana kukana, komanso kuyesa kwamagetsi kumachitidwa kuti zitsimikizire kuti PCB ikukwaniritsa zofunikira. Kuyang'ana kowoneka kumapangidwanso kuti muwone zolakwika zilizonse monga zazifupi, zotseguka, zosokoneza, kapena zolakwika zapagawo.

Njira yopangira ma PCB amagetsi amagalimoto imaphatikizapo masitepe angapo kuyambira pakusankha zinthu mpaka kuyesa ndikuwunika. Gawo lililonse limakhala ndi gawo lofunikira pakuwonetsetsa kudalirika, magwiridwe antchito ndi magwiridwe antchito a PCB yomaliza. Opanga ayenera kutsatira miyezo yamakampani ndi njira zabwino zowonetsetsa kuti ma PCB akukwaniritsa zofunikira zamagalimoto.

4. Zoganizira zagalimoto: pali zinthu zina zamagalimoto zomwe ziyenera kuganiziridwa popanga ndi

kupanga ma PCB agalimoto.

4.1 Kutentha kwa kutentha ndi kayendetsedwe ka kutentha: M'magalimoto, ma PCB amakhudzidwa ndi kutentha kwakukulu chifukwa cha kutentha kwa injini ndi malo ozungulira.Chifukwa chake, kutayika kwa kutentha ndi kasamalidwe ka kutentha ndizofunikira kwambiri pamapangidwe agalimoto a PCB. Zida zopangira kutentha monga zamagetsi zamagetsi, zowongolera ma microcontroller, ndi masensa ziyenera kuyikidwa pa PCB kuti zichepetse kutentha. Masinki otenthetsera ndi ma polowera amapezeka kuti azitha kutenthetsa bwino. Kuonjezera apo, njira zoyenera zoyendetsera mpweya ndi kuziziritsa ziyenera kuphatikizidwa muzojambula zamagalimoto kuti ziteteze kutentha kwakukulu ndikuwonetsetsa kudalirika kwa PCB ndi moyo wautali.

4.2 Kugwedezeka ndi kugwedezeka: Magalimoto amagwira ntchito m'misewu yosiyanasiyana ndipo amatha kugwedezeka ndi kugwedezeka chifukwa cha mabampu, maenje ndi malo ovuta.Kugwedezeka uku ndi kugwedezeka kungakhudze kulimba kwa PCB ndi kudalirika. Kuonetsetsa kukana kugwedezeka ndi kugwedezeka, ma PCB omwe amagwiritsidwa ntchito m'magalimoto ayenera kukhala amphamvu mwamakina komanso okhazikika bwino. Njira zopangira monga kugwiritsa ntchito ma solder owonjezera, kulimbikitsa PCB ndi epoxy kapena zida zolimbikitsira, ndikusankha mosamala zigawo zosagwirizana ndi kugwedezeka ndi zolumikizira zingathandize kuchepetsa zotsatira zoyipa za kugwedezeka ndi kugwedezeka.

4.3 Electromagnetic compatibility (EMC): Electromagnetic interference (EMI) ndi radio frequency interference (RFI) zitha kusokoneza magwiridwe antchito a zida zamagetsi zamagalimoto.Kulumikizana kwapafupi kwa zigawo zosiyanasiyana m'galimoto kumatulutsa minda yamagetsi yomwe imasokonezana. Kuwonetsetsa EMC, mapangidwe a PCB akuyenera kuphatikizirapo njira zotchinjirizira, zoyika pansi, ndi zosefera kuti muchepetse kutulutsa komanso kukhudzidwa ndi ma siginecha amagetsi. Zitini zotchingira, ma conductive spacers, ndi njira zoyenera za masanjidwe a PCB (monga kulekanitsa tcheru cha analogi ndi ma digito) zitha kuthandiza kuchepetsa zotsatira za EMI ndi RFI ndikuwonetsetsa kuti magetsi amagalimoto akuyenda bwino.

4.4 Miyezo yachitetezo ndi yodalirika: Zamagetsi zamagalimoto ziyenera kutsata chitetezo chokwanira komanso kudalirika kuti zitsimikizire chitetezo cha okwera komanso magwiridwe antchito onse agalimoto.Miyezo iyi ikuphatikiza ISO 26262 yachitetezo chogwira ntchito, yomwe imatanthauzira zofunikira zachitetezo pamagalimoto apamsewu, ndi miyezo yosiyanasiyana yapadziko lonse lapansi komanso yapadziko lonse lapansi yachitetezo chamagetsi ndi zoganizira zachilengedwe (monga IEC 60068 pakuyesa zachilengedwe). Opanga ma PCB ayenera kumvetsetsa ndi kutsatira mfundo izi popanga ndi kupanga ma PCB agalimoto. Kuphatikiza apo, kuyezetsa kudalirika monga kuyendetsa njinga yamoto, kuyesa kugwedezeka, ndi kukalamba kofulumira kuyenera kuchitidwa kuti zitsimikizire kuti PCB ikukwaniritsa zofunikira zodalirika zamagalimoto.

Chifukwa cha kutentha kwakukulu kwa chilengedwe cha magalimoto, kutentha kwa kutentha ndi kayendetsedwe ka kutentha ndizofunikira kwambiri. Kugwedezeka ndi kukana kugwedezeka ndikofunikira kuonetsetsa kuti PCB imatha kupirira zovuta zamsewu. Kugwirizana kwa ma elekitiroleti ndikofunikira kuti muchepetse kusokoneza pakati pa zida zamagetsi zamagalimoto. Kuphatikiza apo, kutsatira mfundo zachitetezo ndi kudalirika ndikofunikira kuti mutsimikizire chitetezo ndi magwiridwe antchito agalimoto yanu. Pothetsa mavutowa, opanga PCB amatha kupanga ma PCB apamwamba kwambiri omwe amakwaniritsa zofunikira zamakampani opanga magalimoto.

5.Automotive electronic PCB msonkhano ndi kuphatikiza:

Kusonkhana ndi kuphatikiza kwa PCB zamagetsi zamagetsi kumaphatikizapo magawo osiyanasiyana kuphatikiza kugula zinthu, kusonkhana kwaukadaulo wapamtunda, njira zopangira makina ndi pamanja, ndikuwongolera komanso kuyesa. Gawo lililonse limathandizira kupanga ma PCB apamwamba, odalirika omwe amakwaniritsa zofunikira zamagalimoto zamagalimoto. Opanga ayenera kutsata ndondomeko zokhwima ndi miyezo yapamwamba kuti atsimikizire kugwira ntchito ndi moyo wautali wa zida zamagetsi izi m'magalimoto.

5.1 Kugula kwazinthu: Kugula magawo ndi gawo lofunikira pakusokonekera kwamagalimoto amagetsi a PCB.Gulu logula zinthu limagwira ntchito limodzi ndi ogulitsa kuti apeze ndikugula zinthu zofunika. Zida zosankhidwa ziyenera kukwaniritsa zofunikira pakuchita bwino, kudalirika, komanso kugwirizana ndi ntchito zamagalimoto. Njira yogulira zinthu imaphatikizapo kuzindikira ogulitsa odalirika, kufananiza mitengo ndi nthawi yobweretsera, ndikuwonetsetsa kuti zigawo zake ndi zenizeni komanso zimakwaniritsa zofunikira. Magulu ogula zinthu amaganiziranso zinthu monga kusamalidwa kwanthawi yayitali kuti atsimikizire kupezeka kwa zinthu panthawi yonse ya moyo wazinthu.

5.2 Surface Mount Technology (SMT): Ukadaulo wa Surface Mount (SMT) ndiyo njira yabwino yolumikizira ma PCB amagetsi agalimoto chifukwa chakuchita bwino, kulondola, komanso kugwirizana ndi tinthu tating'onoting'ono. SMT imaphatikizapo kuyika zigawo molunjika pa PCB pamwamba, kuchotsa kufunikira kwa zitsogozo kapena mapini.Zigawo za SMT zimaphatikizapo zida zazing'ono, zopepuka monga zopinga, ma capacitors, mabwalo ophatikizika, ndi ma microcontrollers. Zidazi zimayikidwa pa PCB pogwiritsa ntchito makina oyika okha. Makinawa amayika zida za solder pa PCB, kuwonetsetsa kulondola bwino ndikuchepetsa mwayi wa zolakwika. Njira ya SMT imapereka maubwino angapo, kuphatikiza kachulukidwe kazinthu, kupititsa patsogolo kupanga bwino, komanso kukhathamiritsa kwamagetsi. Kuphatikiza apo, SMT imathandizira kuyang'anira ndi kuyesa zokha, ndikupangitsa kupanga mwachangu komanso kodalirika.

5.3 Kusonkhana pamanja ndi pamanja: Kusonkhana kwa PCB zamagalimoto zamagetsi kumatha kukwaniritsidwa ndi njira zodziwikiratu komanso zamanja, kutengera zovuta za bolodi komanso zofunikira pakugwiritsa ntchito.Kusonkhana kodzichitira kumaphatikizapo kugwiritsa ntchito makina apamwamba kuti asonkhanitse ma PCB mwachangu komanso molondola. Makina odzichitira okha, monga chip mounters, solder paste printer, ndi maovuni obweranso, amagwiritsidwa ntchito poyika zinthu, kugwiritsa ntchito phala la solder, ndi reflow soldering. Kusonkhana pawokha kumakhala kothandiza kwambiri, kumachepetsa nthawi yopanga ndikuchepetsa zolakwika. Komano, kuphatikiza pamanja, kumagwiritsidwa ntchito popanga ma voliyumu otsika kapena pomwe zida zina sizoyenera kusonkhana pawokha. Akatswiri aluso amagwiritsa ntchito zida zapadera ndi zida kuti aziyika mosamala zigawo pa PCB. Kusonkhanitsa pamanja kumapangitsa kusinthasintha kwakukulu ndikusintha mwamakonda kuposa kusonkhanitsa makina, koma kumachedwa komanso kumakonda kulakwitsa kwa anthu.

5.4 Kuwongolera Ubwino ndi Kuyesa: Kuwongolera kwaubwino ndi kuyezetsa ndi njira zofunika kwambiri pakusonkhanitsa ndi kuphatikiza kwamagetsi amagetsi a PCB. Njirazi zimathandiza kuonetsetsa kuti chomaliza chikukwaniritsa miyezo ndi magwiridwe antchito.Kuwongolera kwaubwino kumayamba ndikuwunika zinthu zomwe zikubwera kuti zitsimikizire kuti ndizowona komanso zabwino zake. Pamsonkhanowu, kuwunika kumachitika mosiyanasiyana kuti azindikire ndikuwongolera zolakwika zilizonse kapena zovuta. Kuyang'ana kowoneka bwino, kuyang'ana kowoneka bwino (AOI) ndi kuyang'ana kwa X-ray nthawi zambiri amagwiritsidwa ntchito kuti azindikire zolakwika zomwe zingatheke monga milatho yogulitsira, kusalumikizana bwino kwa zigawo kapena kulumikizana kotseguka.

Pambuyo pa msonkhano, PCB iyenera kuyesedwa kuti itsimikizire momwe ikuyendera. TNjira zama esting zingaphatikizepo kuyesa kwa mphamvu, kuyesa magwiridwe antchito, kuyezetsa mozungulira, ndikuyesa zachilengedwe kuti zitsimikizire magwiridwe antchito, mawonekedwe amagetsi, ndi kudalirika kwa PCB.

Kuwongolera kwaubwino ndi kuyezetsa kumaphatikizanso kutsatiridwa, komwe PCB iliyonse imayikidwa chizindikiro kapena chodziwikiratu kuti iwunikire mbiri yake yopanga ndikuwonetsetsa kuyankha.Izi zimathandiza opanga kuzindikira ndi kukonza zovuta zilizonse ndipo amapereka deta yofunikira kuti apititse patsogolo.

6.Automotive electronic PCB Tsogolo lamakono ndi zovuta: Tsogolo la PCB zamagalimoto zamagetsi lidzatengera

mayendedwe monga miniaturization, kuchulukirachulukira, kuphatikiza kwaukadaulo wapamwamba, komanso kufunikira kopititsa patsogolo

njira zopangira.

6.1 Miniaturization ndi kuchulukirachulukira: Chimodzi mwazinthu zofunika pama PCB amagetsi amagalimoto ndikukankhira kosalekeza kwa miniaturization ndi zovuta.Magalimoto akakhala apamwamba kwambiri komanso okhala ndi makina osiyanasiyana amagetsi, kufunikira kwa ma PCB ang'onoang'ono komanso olimba kukukulirakulira. Miniaturization iyi imabweretsa zovuta pakuyika kwa zigawo, njira, kutayika kwamafuta, komanso kudalirika. Opanga PCB ndi opanga ayenera kupeza njira zatsopano zothanirana ndi zinthu zomwe zikucheperachepera ndikusunga magwiridwe antchito a PCB ndi kulimba.

6.2 Kuphatikizika kwa matekinoloje apamwamba: Makampani opanga magalimoto akuwona kupita patsogolo kofulumira kwaukadaulo, kuphatikiza kuphatikiza umisiri wotsogola m'magalimoto.Ma PCB amatenga gawo lalikulu pakupangitsa matekinolojewa, monga zida zapamwamba zothandizira madalaivala (ADAS), makina oyendetsa magalimoto amagetsi, njira zolumikizirana ndi zida zoyendetsera galimoto. matekinoloje apamwambawa amafuna ma PCB omwe amatha kuthandizira kuthamanga kwambiri, kugwiritsira ntchito deta yovuta, ndikuwonetsetsa kulankhulana kodalirika pakati pa zigawo zosiyanasiyana ndi machitidwe. Kupanga ndi kupanga ma PCB omwe amakwaniritsa zofunikirazi ndizovuta kwambiri pamakampani.

6.3 Ntchito yopangira zinthu iyenera kulimbikitsidwa: Pamene kufunikira kwa ma PCB amagetsi a galimoto kukukulirakulirabe, opanga akukumana ndi vuto lokulitsa njira zopangira zinthu kuti akwaniritse miyeso yapamwamba yopangira pamene akusunga miyezo yapamwamba.Kuwongolera njira zopangira, kuwongolera magwiridwe antchito, kufupikitsa nthawi yozungulira komanso kuchepetsa zolakwika ndi malo omwe opanga amayenera kuyang'ana zoyesayesa zawo. Kugwiritsa ntchito matekinoloje apamwamba opangira zinthu, monga makina opangira makina, ma robotiki ndi njira zowunikira zapamwamba, zimathandizira kukonza bwino komanso kulondola kwazomwe amapanga. Kutengera malingaliro a Viwanda 4.0 monga Internet of Things (IoT) ndi kusanthula kwa data kumatha kupereka zidziwitso zofunikira pakukhathamiritsa kwadongosolo komanso kukonza zolosera, potero kumakulitsa zokolola ndi zotuluka.

7.Wodziwika bwino wopanga ma board oyendetsa magalimoto:

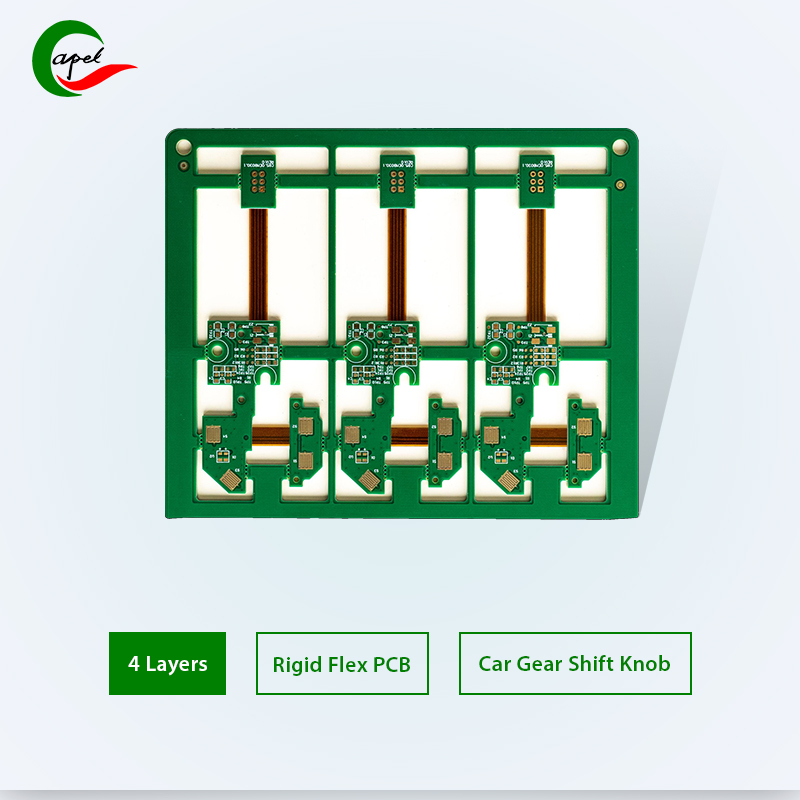

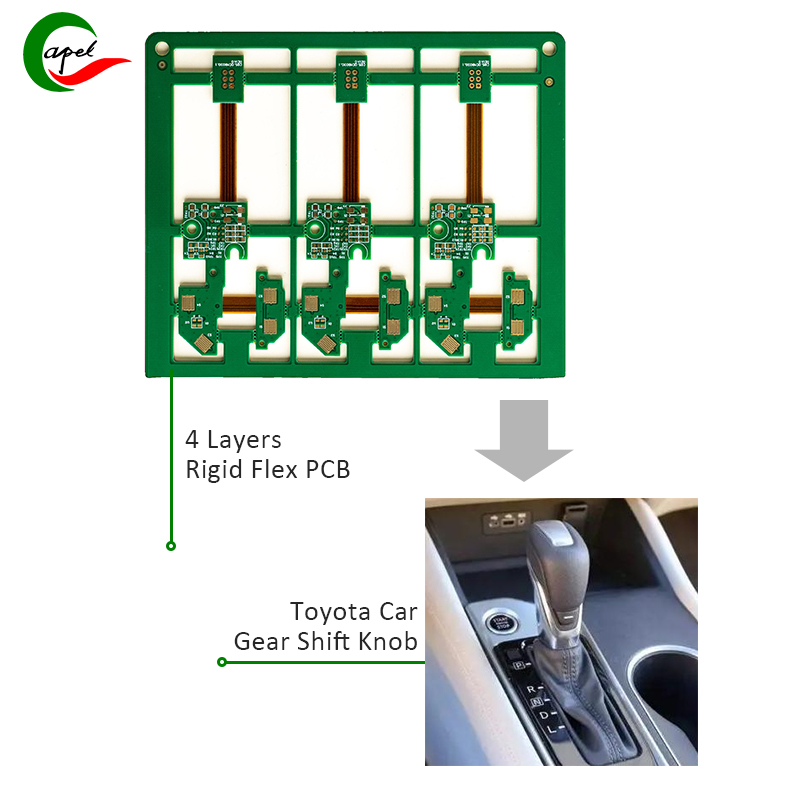

Shenzhen Capel Technology Co., Ltd. idakhazikitsa fakitale ya board board mu 2009 ndipo idayamba kupanga ndikupanga ma board osinthika, ma hybrid board, ndi ma board olimba. Pazaka 15 zapitazi, takwanitsa kukwaniritsa masauzande masauzande ambiri a ma projekiti oyendetsa magalimoto kwamakasitomala, tapeza zambiri pamakampani opanga magalimoto, komanso kupatsa makasitomala mayankho otetezeka komanso odalirika. Akatswiri aukadaulo a Capel ndi magulu a R&D ndi akatswiri omwe mungakhulupirire!

Powombetsa mkota,njira yopangira zida zamagalimoto za PCB ndi ntchito yovuta komanso yosamala yomwe imafuna mgwirizano wapakati pakati pa mainjiniya, opanga, ndi opanga. Zofunikira zamagalimoto zamagalimoto zimafunikira ma PCB apamwamba, odalirika komanso otetezeka. Pamene ukadaulo ukupitilirabe patsogolo, ma PCB amagetsi agalimoto adzafunika kukwaniritsa kufunikira kwa ntchito zovuta komanso zovuta. Kuti akhale patsogolo pa gawo lomwe likukula mwachanguli, opanga ma PCB akuyenera kutsatira zomwe zachitika posachedwa. Ayenera kuyika ndalama m'njira zapamwamba zopangira ndi zida kuti awonetsetse kupanga ma PCB apamwamba kwambiri. Kugwiritsa ntchito machitidwe apamwamba sikungowonjezera luso loyendetsa galimoto, komanso kumaika patsogolo chitetezo ndi kulondola.

Nthawi yotumiza: Sep-11-2023

Kubwerera