Tsegulani:

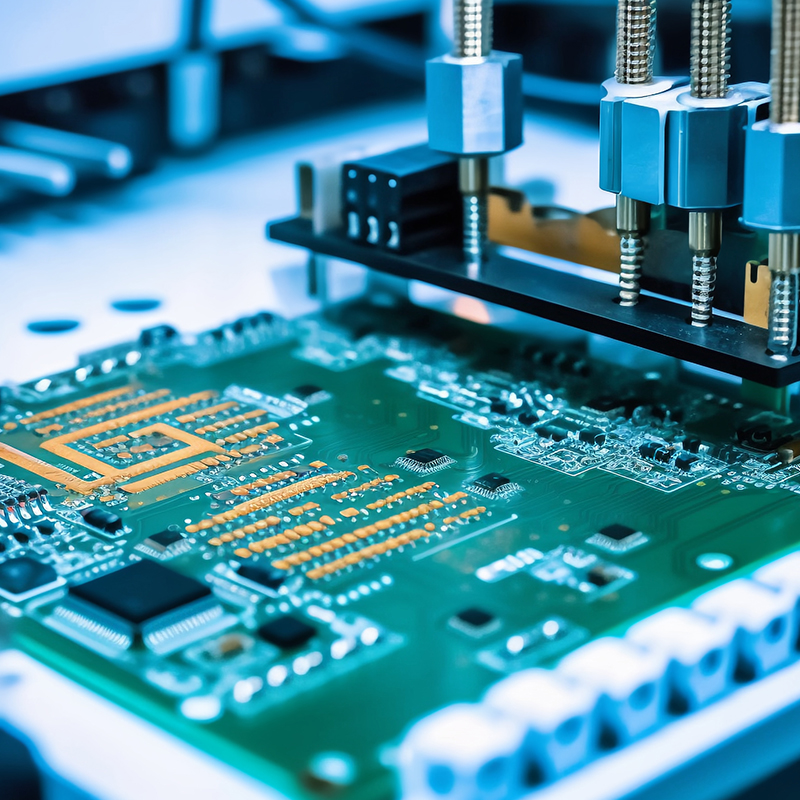

Circuit board kuwotcherera ndi njira yofunika kwambiri pamakampani opanga zamagetsi, kuwonetsetsa kuti zimagwira ntchito bwino komanso kudalirika kwa zida zamagetsi. Komabe, monga njira iliyonse yopangira zinthu, sizikhala ndi zovuta zake.Mu blog iyi, tikhala tikuzama m'mabvuto omwe amapezeka kwambiri akamazungulira matabwa ndikuwunika njira zothetsera mavutowo.

1. PCB board short circuit:

Imodzi mwamavuto omwe amafala kwambiri pa board board soldering ndi mabwalo amfupi. Dera lalifupi limachitika pomwe panopo imatenga njira yosayembekezereka chifukwa cha kulumikizana kocheperako pakati pa mfundo ziwiri pagawo. Izi zitha kuchitika chifukwa cha zinthu zosiyanasiyana, monga milatho ya solder, zinyalala zosokera, kapena zolakwika zamapangidwe.

yankho:

Kuti mupewe maulendo afupikitsa, ndikofunikira kuyang'anitsitsa ndikuyesa bolodi pambuyo pa soldering. Kugwiritsa ntchito ukadaulo wa automated optical inspection (AOI) kungathandize kwambiri kuzindikira zovuta zomwe zingachitike. Kuphatikiza apo, kugwiritsa ntchito zida zowotchera mwatsatanetsatane, monga chitsulo chosungunulira chowongolera kutentha, kungathandize kupewa solder yochulukirapo kuti ipange kulumikizana mwangozi.

2. Zolumikizana zakuda ndi zonyansa:

Zolumikizana zakuda ndi zonyowa pa PCB zitha kuwonetsa kulumikizidwa kolakwika kwa solder. Vutoli nthawi zambiri limayamba chifukwa cha kusamutsidwa kwa kutentha kosakwanira panthawi ya soldering, zomwe zimapangitsa kunyowetsa kosakwanira kwa olowa.

yankho:

Kuti mukwaniritse kunyowetsa koyenera ndikupewa kukhudzana kwakuda, kopanda mbewu, zowotcherera ziyenera kukonzedwa bwino. Onetsetsani kuti nsonga yachitsulo chowuchirira ndi yoyera, yotsekeredwa m'zitini, komanso pa kutentha koyenera. Kuphatikiza apo, kugwiritsa ntchito flux panthawi ya soldering kumatha kupititsa patsogolo kuyenda kwa solder ndikuwongolera mapangidwe olumikizana. Flux imathandizira kuchotsa ma oxide ndi zoyipitsidwa pamalo azitsulo, kumathandizira kunyowetsa bwino komanso malo olumikizirana amphamvu.

3. Zolumikizira za PCB zimasanduka chikasu chagolide:

Pamene olowa solder pa PCB padziko kutembenukira golide chikasu, izo zikusonyeza kuti pali mavuto monga olakwika solder aloyi zikuchokera kapena olakwika soldering luso. Nkhaniyi ikhoza kusokoneza kukhulupirika ndi kudalirika kwa bolodi la dera.

yankho:

Kugwiritsa ntchito alloy yolondola ya solder ndikofunikira kuti mutsimikizire kutalika kwa bolodi lanu lozungulira. Nthawi zonse tsatirani zolemba zamakampani aloyi ndipo pewani kugwiritsa ntchito zinthu zotsika mtengo kapena zosatsimikizika. Kuonjezera apo, kusunga kutentha koyenera kwa soldering ndi kugwiritsa ntchito njira zoyenera zogulitsira, kuphatikizapo kutentha kwa PCB ndi kugwiritsa ntchito solder yoyenera, kungathandize kupeza zida zamtengo wapatali za golide.

4. Kukhudzidwa kwa chilengedwe pazovuta za board board:

Malo omwe matabwa ozungulira amagulitsidwa amathanso kukhudza kwambiri khalidwe la mankhwala omaliza. Zinthu monga chinyezi, kusinthasintha kwa kutentha, ndi zowononga mpweya zimatha kuyambitsa zolakwika zosiyanasiyana pama board ozungulira.

yankho:

Kuti muchepetse kuwonongeka kwa chilengedwe pazowonongeka za board board, ndikofunikira kukhazikitsa malo owongolera opanga. Zowonongeka zomwe zimachitika chifukwa cha magetsi osasunthika zitha kupewedwa potsatira njira zoyenera za ESD (electrostatic discharge), monga kugwiritsa ntchito malo otetezedwa a ESD komanso kuvala zida zodzitchinjiriza. Kuphatikiza apo, kusunga kutentha ndi chinyezi choyenera m'malo opangirako kumathandizira kupewa zovuta monga kuwotcherera ndi kuwonongeka kwa zinthu.

Pomaliza:

Circuit board soldering ndi njira yovuta yomwe imafuna kulondola komanso kusamala mwatsatanetsatane.Pothetsa mavuto omwe amapezeka nthawi zambiri, opanga amatha kuonetsetsa kuti akupanga zipangizo zamakono, zodalirika. Kukhazikitsa mayankho omwe takambirana mubulogu iyi, monga njira zowunikira bwino, zowongoleredwa bwino, komanso kuwongolera chilengedwe, zitha kupititsa patsogolo kwambiri kuwongolera kwa board board.

Nthawi yotumiza: Oct-23-2023

Kubwerera