Nkhaniyi ipereka chiwongolero chokwanira cha njira yochizira pamwamba pakupanga FPC Flex PCB. Kuchokera pakufunika kokonzekera pamwamba kupita ku njira zosiyanasiyana zokutira pamwamba, tidzakambirana mfundo zazikuluzikulu kuti zikuthandizeni kumvetsetsa ndi kukhazikitsa ndondomeko yokonzekera pamwamba.

Chiyambi:

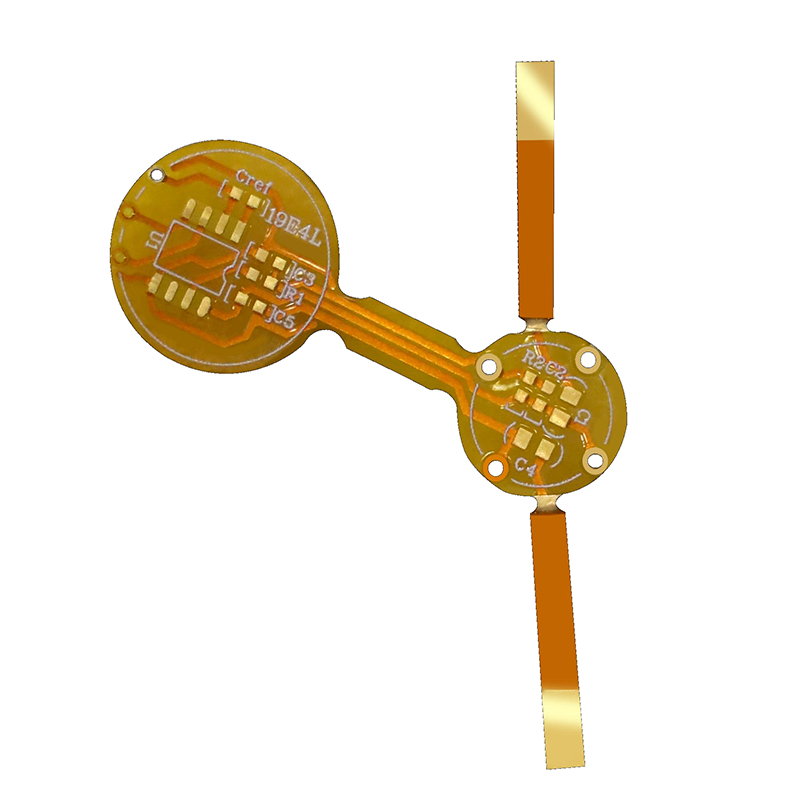

Ma Flexible PCBs (Flexible Printed Circuit Boards) ayamba kutchuka m'mafakitale osiyanasiyana chifukwa chochita zinthu zambiri komanso amatha kuzolowera mawonekedwe ovuta. Njira zokonzekera pamwamba zimagwira ntchito yofunika kwambiri powonetsetsa kuti mabwalo osinthikawa akuyenda bwino komanso odalirika. Nkhaniyi ipereka chiwongolero chokwanira cha njira yochizira pamwamba pakupanga FPC Flex PCB. Kuchokera pakufunika kokonzekera pamwamba kupita ku njira zosiyanasiyana zokutira pamwamba, tidzakambirana mfundo zazikuluzikulu kuti zikuthandizeni kumvetsetsa ndi kukhazikitsa ndondomeko yokonzekera pamwamba.

Zamkatimu:

1. Kufunika kwa chithandizo chapamwamba pakupanga FPC flex PCB:

Kuchiza pamwamba ndikofunikira pakupanga ma FPC Flexible board chifukwa amagwira ntchito zingapo. Imathandizira soldering, imatsimikizira kumamatira bwino, komanso imateteza ma conductive ku makutidwe ndi okosijeni komanso kuwonongeka kwa chilengedwe. Kusankhidwa ndi ubwino wa chithandizo chapamwamba zimakhudza mwachindunji kudalirika ndi ntchito yonse ya PCB.

Kumaliza pamwamba pakupanga FPC Flex PCB kumagwira ntchito zingapo zofunika.Choyamba, imathandizira kugulitsa, kuonetsetsa kulumikizana koyenera kwa zida zamagetsi ku PCB. The pamwamba mankhwala timapitiriza solderability kwa amphamvu ndi odalirika kugwirizana chigawo chimodzi ndi PCB. Popanda kukonzekera bwino pamwamba, zida za solder zimatha kukhala zofooka komanso zolephera, zomwe zimapangitsa kuti zikhale zosayenera komanso zowonongeka kwa dera lonse.

Chinthu chinanso chofunikira pakukonzekera pamwamba pakupanga FPC Flex PCB ndikuwonetsetsa kumamatira kwabwino.Ma FPC flex PCB nthawi zambiri amapindika kwambiri komanso kusinthasintha panthawi yautumiki, zomwe zimayika kupsinjika pa PCB ndi zigawo zake. Kuchiza pamwamba kumapereka chitetezo chokwanira kuti chitsimikizidwe kuti chigawocho chikutsatiridwa mwamphamvu ku PCB, kuteteza kutayika kapena kuwonongeka komwe kungawonongeke panthawi yogwira. Izi ndizofunikira makamaka pakugwiritsa ntchito komwe kupsinjika kwamakina kapena kugwedezeka kumakhala kofala.

Kuphatikiza apo, chithandizo chapamwamba chimateteza mawonekedwe a FPC Flex PCB ku okosijeni ndi kuwonongeka kwa chilengedwe.Ma PCB awa nthawi zonse amakumana ndi zinthu zosiyanasiyana zachilengedwe monga chinyezi, kusintha kwa kutentha ndi mankhwala. Popanda kukonzekera kokwanira pamwamba, ma conductive amatha kuwononga pakapita nthawi, zomwe zimapangitsa kulephera kwa magetsi komanso kulephera kwa dera. Chithandizo chapamwamba chimakhala ngati chotchinga, kuteteza PCB ku chilengedwe ndikuwonjezera moyo wake ndi kudalirika.

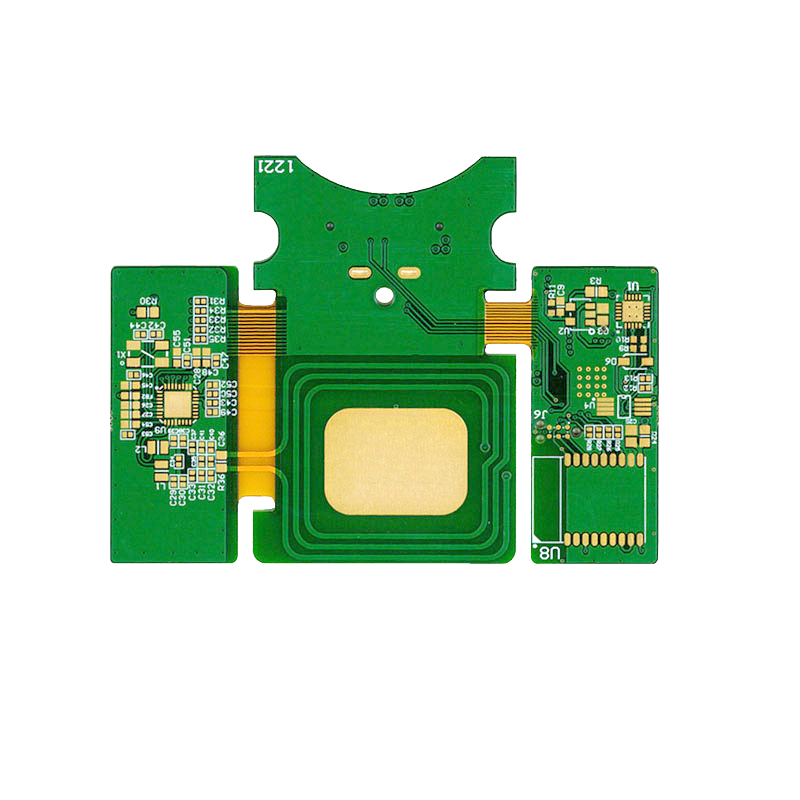

2.Njira zochiritsira zodziwika bwino za FPC flex PCB kupanga:

Gawoli likambirana mwatsatanetsatane njira zochizira zomwe zimagwiritsidwa ntchito kwambiri pakupanga ma FPC Flexible board, kuphatikiza Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), Immersion Tin (ISn) ndi electroplating. (E-plating). Njira iliyonse idzafotokozedwa pamodzi ndi ubwino wake ndi zovuta zake.

Hot Air Solder Leveling (HASL):

HASL ndi njira yochizira pamwamba yomwe imagwiritsidwa ntchito kwambiri chifukwa champhamvu komanso yotsika mtengo. Njirayi imaphatikizapo kuphimba pamwamba pa mkuwa ndi nsonga ya solder, yomwe imatenthedwa ndi mpweya wotentha kuti ikhale yosalala, yosalala. HASL imapereka kugulitsa kwabwino kwambiri ndipo imagwirizana ndi magawo osiyanasiyana komanso njira zogulitsira. Komabe, ilinso ndi malire monga kumaliza kwapamwamba komanso kuwonongeka komwe kungawononge ma marked panthawi yokonza.

Electroless Nickel Immersion Gold (ENIG):

ENIG ndi chisankho chodziwika bwino pakupanga ma flex circuit chifukwa chakuchita bwino komanso kudalirika. Njirayi imaphatikizapo kuyika faifi wopyapyala pamwamba pa mkuwa kudzera mu kachitidwe ka mankhwala, kenaka amamizidwa mu njira ya electrolyte yokhala ndi tinthu tagolide. ENIG ili ndi kukana kwa dzimbiri, kugawa makulidwe ofanana komanso kugulitsa bwino. Komabe, kukwera mtengo kokhudzana ndi ndondomeko komanso zovuta za pad zakuda ndi zina mwazovuta zomwe muyenera kuziganizira.

Organic Solderability Preservative (OSP):

OSP ndi njira yochizira pamwamba yomwe imaphatikizapo kuphimba pamwamba pa mkuwa ndi filimu yopyapyala kuti iteteze ku okosijeni. Njirayi ndi yogwirizana ndi chilengedwe chifukwa imathetsa kufunika kwa zitsulo zolemera. OSP imapereka malo athyathyathya komanso kusungunuka kwabwino, ndikupangitsa kuti ikhale yoyenera pazigawo zabwino za phula. Komabe, OSP ili ndi nthawi ya alumali yochepa, imakhudzidwa ndi kagwiridwe, ndipo imafuna malo oyenera osungira kuti ikhale yogwira mtima.

Kumiza malata (ISn):

ISn ndi njira yochizira pamwamba yomwe imaphatikizapo kumiza dera losinthika mu bafa la malata osungunuka. Izi zimapanga chitsulo chochepa kwambiri cha malata pamtunda wamkuwa, womwe uli ndi solderability, flatness ndi kukana dzimbiri. ISn imapereka kumaliza kosalala pamwamba kumapangitsa kukhala koyenera kugwiritsa ntchito mawu abwino. Komabe, ili ndi kukana kutentha pang'ono ndipo ingafunike kugwiridwa mwapadera chifukwa cha brittleness ya malata.

Electroplating (E plating):

Electroplating ndi njira yodziwika bwino yochizira pamwamba pakupanga makina osinthika. Njirayi imaphatikizapo kuyika chitsulo pamwamba pa mkuwa pogwiritsa ntchito electrochemical reaction. Kutengera ndi zomwe mukufuna kugwiritsa ntchito, electroplating imapezeka munjira zosiyanasiyana monga golide, siliva, faifi tambala kapena malata. Amapereka kulimba kwambiri, kusungunuka komanso kukana kwa dzimbiri. Komabe, ndizokwera mtengo poyerekeza ndi njira zina zochizira pamwamba ndipo zimafuna zida zovuta ndi zowongolera.

3.Kusamala posankha njira yolondola yochizira pamwamba pakupanga FPC flex PCB:

Kusankha kumaliza koyenera kwa mabwalo osinthika a FPC kumafuna kuwunika mosamalitsa zinthu zosiyanasiyana monga kagwiritsidwe ntchito, momwe chilengedwe, zofunika kugulitsira, komanso kukwera mtengo kwake. Gawoli lipereka chitsogozo pakusankha njira yoyenera potengera malingaliro awa.

Dziwani zomwe makasitomala amafuna:

Musanafufuze zamankhwala osiyanasiyana omwe alipo, ndikofunikira kumvetsetsa bwino zomwe makasitomala amafuna. Ganizirani zinthu zotsatirazi:

Ntchito:

Dziwani zomwe mukufuna kugwiritsa ntchito FPC flexible PCB yanu. Kodi ndi zamagetsi zamagetsi, zamagalimoto, zamankhwala kapena zida zamafakitale? Makampani aliwonse amatha kukhala ndi zofunikira zenizeni, monga kukana kutentha kwambiri, mankhwala kapena kupsinjika kwamakina.

Zachilengedwe:

Unikani zochitika zachilengedwe zomwe PCB ingakumane nazo. Kodi idzakumana ndi chinyezi, chinyezi, kutentha kwambiri kapena zinthu zowononga? Zinthu izi zidzakhudza njira yokonzekera pamwamba kuti ipereke chitetezo chabwino kwambiri ku oxidation, dzimbiri ndi kuwonongeka kwina.

Zofunikira za Solderability:

Unikani zofunikira za solderability za FPC flexible PCB. Kodi bolodi idzadutsa muzitsulo zowotchera kapena zowotchera? Mankhwala osiyanasiyana apamwamba amayenderana mosiyana ndi njira zowotcherera. Kutengera izi kuonetsetsa olowa odalirika solder ndi kupewa mavuto monga solderability zilema ndi kutsegula.

Onani Njira Zochizira Pamwamba:

Pomvetsetsa zofunikira za makasitomala, ndi nthawi yoti mufufuze chithandizo chamankhwala chomwe chilipo:

Organic Solderability Preservative (OSP):

OSP ndi chida chodziwika bwino chamankhwala amtundu wa FPC flexible PCB chifukwa cha kutsika mtengo komanso mawonekedwe oteteza chilengedwe. Amapereka chitetezo chocheperako chomwe chimalepheretsa makutidwe ndi okosijeni komanso chimathandizira kugulitsa. Komabe, OSP ikhoza kukhala ndi chitetezo chochepa kumadera ovuta komanso moyo wamfupi wa alumali kuposa njira zina.

Electroless Nickel Immersion Gold (ENIG):

ENIG imagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana chifukwa chogulitsa kwambiri, kukana dzimbiri komanso kusalala. Chosanjikiza cha golide chimatsimikizira kulumikizana kodalirika, pomwe wosanjikiza wa nickel umapereka kukana kwa okosijeni kwabwino komanso kutetezedwa koopsa kwa chilengedwe. Komabe, ENIG ndiyokwera mtengo poyerekeza ndi njira zina.

Golide Wolimba Wopangidwa ndi Electroplated (Golide Wolimba):

Golide wolimba ndi wokhazikika kwambiri ndipo amapereka kudalirika kwabwino kwambiri, ndikupangitsa kuti ikhale yoyenera kugwiritsa ntchito zomwe zimaphatikizapo kuyika mobwerezabwereza komanso malo ovala kwambiri. Komabe, ndiye njira yomaliza yokwera mtengo kwambiri ndipo singafunike pakugwiritsa ntchito kulikonse.

Nickel Wopanda Electroless Palladium Immersion Gold (ENEPIG):

ENEPIG ndi multifunctional pamwamba mankhwala wothandizira oyenera ntchito zosiyanasiyana. Zimaphatikiza ubwino wa nickel ndi golide wosanjikiza ndi phindu lowonjezera la palladium wosanjikiza wapakatikati, kupereka kukhazikika kwa waya komanso kukana dzimbiri. Komabe, ENEPIG imakonda kukhala yokwera mtengo komanso yovuta kuikonza.

4.Comprehensive Step-by-step Guide to Surface Preparation process mu FPC flex PCB kupanga:

Kuti muwonetsetse kukhazikitsidwa bwino kwa njira zokonzekera pamwamba, ndikofunikira kutsatira mwadongosolo. Gawoli lipereka chitsogozo chatsatane-tsatane chokhudza kuchiritsa, kuyeretsa mankhwala, kugwiritsa ntchito flux, zokutira pamwamba ndi njira zochiritsira pambuyo pake. Gawo lirilonse likufotokozedwa bwino, ndikuwunikira njira zoyenera ndi machitidwe abwino.

Gawo 1: Kukonzekeratu

Kukonzekera koyambirira ndi sitepe yoyamba yokonzekera pamwamba ndipo kumaphatikizapo kuyeretsa ndi kuchotsa zowonongeka pamtunda.

Choyamba, yang'anani pamwamba kuti muwone kuwonongeka kulikonse, zolakwika kapena dzimbiri. Nkhanizi ziyenera kuthetsedwa musanachitepo kanthu. Kenaka, gwiritsani ntchito mpweya woponderezedwa, burashi, kapena vacuum kuchotsa tinthu tating'ono, fumbi, kapena dothi. Pofuna kuipitsidwa kwambiri, gwiritsani ntchito zosungunulira kapena zotsukira mankhwala opangira zinthu zapamtunda. Onetsetsani kuti pamwamba ndi youma bwino mukatha kuyeretsa, chifukwa chinyezi chotsalira chingalepheretse njira zotsatila.

Gawo 2: Kuyeretsa Chemical

Kuyeretsa mankhwala kumaphatikizapo kuchotsa zonyansa zilizonse zotsalira pamwamba.

Sankhani mankhwala oyenera oyeretsera potengera zinthu zapamtunda ndi mtundu wa kuipitsidwa. Ikani zotsukira mofanana pamwamba ndi kulola nthawi yokwanira yolumikizana kuti muchotse bwino. Gwiritsani ntchito burashi kapena scouring pad kuti mukolose pansi pang'onopang'ono, kulabadira madera ovuta kufika. Muzimutsuka bwino pamwamba ndi madzi kuchotsa zotsalira za chotsukira. Njira yoyeretsera mankhwala imatsimikizira kuti pamwamba pake ndi oyera komanso okonzeka kukonzedwanso.

Khwerero 3: Kugwiritsa Ntchito Flux

Kugwiritsa ntchito flux ndikofunikira kwambiri pakuwotcha kapena kuwotcha chifukwa kumathandizira kumamatira bwino komanso kumachepetsa makutidwe ndi okosijeni.

Sankhani mtundu woyenera wa flux molingana ndi zida zomwe zikuyenera kulumikizidwa komanso zofunikira zenizeni. Ikani flux mofanana kumalo ophatikizana, kuonetsetsa kuti kutsekedwa kwathunthu. Samalani kuti musagwiritse ntchito mopitirira muyeso chifukwa zingayambitse vuto la soldering. Flux iyenera kugwiritsidwa ntchito nthawi yomweyo isanayambe kutsekemera kapena kutsekemera kuti ikhale yogwira mtima.

Gawo 4: zokutira pamwamba

Zopaka pamwamba zimathandizira kuteteza malo ku chilengedwe, kupewa dzimbiri komanso kukulitsa mawonekedwe awo.

Musanagwiritse ntchito zokutira, konzekerani motsatira malangizo a wopanga. Ikani chovalacho mosamala pogwiritsa ntchito burashi, roller kapena sprayer, kuonetsetsa kuti chivundikirocho chikhale chosalala komanso chosalala. Zindikirani nthawi yoyenera kuyanika kapena kuchiritsa pakati pa malaya. Kuti mupeze zotsatira zabwino, sungani malo oyenera a chilengedwe monga kutentha ndi chinyezi panthawi yochiritsa.

Khwerero 5: Kukonzekera pambuyo

Njira yothandizira pambuyo pa chithandizo ndi yofunika kwambiri kuti zitsimikizidwe kuti nthawi yayitali yophimba pamwamba ndi ubwino wonse wa malo okonzeka.

Chophimbacho chikachiritsidwa kwathunthu, yang'anani zolakwika zilizonse, thovu kapena kusalingana. Konzani mavutowa popukuta kapena kupukuta pamwamba, ngati kuli kofunikira. Kusamalira ndi kuyang'anitsitsa nthawi zonse n'kofunika kuti muzindikire zizindikiro zilizonse zowonongeka kapena zowonongeka mu zokutira kuti zitha kukonzedwa mwamsanga kapena kuwonjezeredwa ngati pakufunika.

5.Quality Control and Testing in FPC flex PCB kupanga pamwamba mankhwala njira:

Kuwongolera kwaubwino ndi kuyezetsa ndikofunikira kuti muwonetsetse kuti njira zokonzekera pamwamba zikuyenda bwino. Gawoli lidzakambirana njira zosiyanasiyana zoyesera, kuphatikizapo kuyang'ana kowoneka, kuyesa zomatira, kuyesa kugulitsa, ndi kuyesa kudalirika, kuti zitsimikizidwe kuti zimakhala zokhazikika komanso zodalirika pakupanga mankhwala a FPC Flex PCBs.

Kuyang'ana kowoneka:

Kuyang'ana kowoneka ndi gawo lofunikira koma lofunikira pakuwongolera khalidwe. Zimaphatikizanso kuyang'ana pamwamba pa PCB kuti muwone zolakwika zilizonse monga zokala, makutidwe ndi okosijeni kapena kuipitsidwa. Kuyang'ana kumeneku kutha kugwiritsa ntchito zida zowonera kapena maikulosikopu kuti azindikire zolakwika zilizonse zomwe zingakhudze magwiridwe antchito kapena kudalirika kwa PCB.

Kuyesa kwa Adhesion:

Kuyesa kumamatira kumagwiritsidwa ntchito poyesa mphamvu yomatira pakati pa chithandizo chapamwamba kapena zokutira ndi gawo lapansi. Mayesowa amawonetsetsa kuti kumaliza kumalumikizidwa mwamphamvu ku PCB, kuletsa delamination kapena kusenda msanga. Kutengera zofunikira ndi miyezo, njira zosiyanasiyana zoyesera zomatira zitha kugwiritsidwa ntchito, monga kuyezetsa matepi, kuyezetsa kukanda kapena kuyesa kukoka.

Kuyesa kwa Solderability:

Kuyesa kwa solderability kumatsimikizira kuthekera kwa chithandizo chapamwamba kuti chithandizire kugulitsa. Mayesowa amaonetsetsa kuti PCB yokonzedwa imatha kupanga zolumikizira zolimba komanso zodalirika zogulitsira ndi zida zamagetsi. Njira zodziwikiratu zoyezetsa zowotchera zimaphatikiza kuyesa kuyandama kwa solder, kuyesa konyowa kwa solder, kapena kuyesa kuyeza kwa mpira wa solder.

Kuyesa Kudalirika:

Kuyezetsa kudalirika kumayesa kugwira ntchito kwanthawi yayitali komanso kulimba kwa ma FPC Flex PCB otetezedwa pansi pamikhalidwe yosiyanasiyana. Mayesowa amathandizira opanga kuwunika kukana kwa PCB pakuyenda panjinga kutentha, chinyezi, dzimbiri, kupsinjika kwamakina, ndi zinthu zina zachilengedwe. Kuyesa kofulumira kwa moyo komanso kuyesa koyerekeza zachilengedwe, monga kukwera njinga yamoto, kuyesa kupopera mchere wamchere kapena kuyesa kugwedezeka, nthawi zambiri amagwiritsidwa ntchito poyesa kudalirika.

Pokhazikitsa njira zowongolera ndi kuyesa kwazinthu zonse, opanga amatha kuwonetsetsa kuti ma FPC Flex PCB omwe ali pamtunda akutsatira miyezo ndi zofunikira. Njirazi zimathandizira kuzindikira zolakwika zilizonse kapena kusagwirizana kulikonse koyambirira pakupanga kotero kuti zowongolera zitha kuchitidwa munthawi yake ndikuwongolera kudalirika kwazinthu zonse komanso kudalirika.

6.Kuthetsa mavuto okonzekera pamwamba pakupanga FPC flex PCB:

Nkhani zochizira pamwamba zitha kuchitika panthawi yopanga, zomwe zimakhudza mtundu wonse ndi magwiridwe antchito a FPC flexible PCB. Gawoli lizindikira zovuta zomwe zimachitika pokonzekera pamwamba ndikupereka malangizo othana ndi mavutowa.

Kumamatira Koyipa:

Ngati kutsirizitsa sikumamatira bwino ku gawo lapansi la PCB, kungayambitse delamination kapena peeling. Izi zikhoza kukhala chifukwa cha kukhalapo kwa zonyansa, kusakwanira kwapamwamba kwapamwamba, kapena kusagwira ntchito kwapamwamba. Pofuna kuthana ndi izi, onetsetsani kuti PCB pamwamba ndi bwino kutsukidwa kuchotsa kuipitsidwa kapena zotsalira pamaso akugwira. Kuphatikiza apo, konzani kuuma kwapamwamba ndikuwonetsetsa kuti njira zoyenera zoyatsira pamwamba, monga chithandizo cha plasma kapena kuyambitsa kwamankhwala, zimagwiritsidwa ntchito kupititsa patsogolo kumamatira.

Kupaka kosiyana kapena makulidwe a plating:

Kupaka kosiyana kapena makulidwe a plating kumatha kukhala chifukwa cha kusakwanira kowongolera njira kapena kusiyanasiyana kwa makulidwe apamwamba. Vutoli limakhudza magwiridwe antchito komanso kudalirika kwa PCB. Kuti muthane ndi vutoli, yambitsani ndikuwunika njira zoyenera monga zokutira kapena kuyika nthawi, kutentha ndi kuyika yankho. Yesetsani kugwedezeka kapena kunjenjemera koyenera pakuyala kapena kuyika kuti mutsimikizire kugawa kofanana.

Oxidation:

Ma PCB okhala ndi oxidizing amatha kukhala oxidize chifukwa cha kukhudzana ndi chinyezi, mpweya, kapena ma oxidizing agents. Oxidation imatha kupangitsa kuti pakhale kusakhazikika bwino ndikuchepetsa magwiridwe antchito onse a PCB. Pofuna kuchepetsa makutidwe ndi okosijeni, gwiritsani ntchito mankhwala oyenerera a pamwamba monga zokutira organic kapena mafilimu oteteza kuti muteteze ku chinyezi ndi oxidizing. Gwiritsani ntchito kasamalidwe koyenera ndi kasungidwe kuti muchepetse kukhudzana ndi mpweya ndi chinyezi.

Kuipitsidwa:

Kuipitsidwa kwa pamwamba pa PCB kumatha kusokoneza kumamatira ndi kusungunuka kwa mapeto a pamwamba. Zoyipa zodziwika bwino zimaphatikizapo fumbi, mafuta, zisindikizo zala, kapena zotsalira kuchokera m'njira zam'mbuyomu. Pofuna kuthana ndi izi, yambitsani pulogalamu yoyeretsa yogwira ntchito kuti muchotse zonyansa zilizonse musanakonzekere pamwamba. Gwiritsani ntchito njira zoyenera zotayira kuti muchepetse kukhudzana ndi manja kapena njira zina zoipitsira.

Kusakhazikika bwino:

Kusokonekera koyipa kumatha chifukwa cha kusowa kwa kutsegulira kapena kuipitsidwa pa PCB pamwamba. Kusagulitsa bwino kungayambitse kuwonongeka kwa weld ndi mafupa ofooka. Kuti muwonjezere kugulitsa, onetsetsani kuti njira zoyenera zoyatsira pamwamba monga chithandizo cha plasma kapena kuyambitsa kwamankhwala zimagwiritsidwa ntchito kupititsa patsogolo kunyowetsa pamwamba pa PCB. Komanso, gwiritsani ntchito pulogalamu yoyeretsa bwino kuti muchotse zonyansa zilizonse zomwe zingalepheretse kuwotcherera.

7. Kukula kwamtsogolo kwa FPC flex board kupanga pamwamba mankhwala:

Gawo la kumaliza kwapamwamba kwa ma FPC osinthika a PCB akupitilizabe kusinthika kuti akwaniritse zosowa zamaukadaulo ndi ntchito zomwe zikubwera. Gawoli likambirana zomwe zingachitike m'tsogolo mwa njira zochizira pamwamba monga zida zatsopano, umisiri wapamwamba wokutikira, ndi njira zothetsera chilengedwe.

Chitukuko chomwe chingakhalepo mtsogolo mwa chithandizo chapamwamba cha FPC ndikugwiritsa ntchito zida zatsopano zokhala ndi zida zowonjezera.Ofufuza akuwunika kugwiritsa ntchito zokutira zatsopano ndi zida kuti apititse patsogolo magwiridwe antchito komanso kudalirika kwa ma PCB osinthika a FPC. Mwachitsanzo, zokutira zodzitchinjiriza zikufufuzidwa, zomwe zimatha kukonza zowonongeka kapena zokopa pamwamba pa PCB, potero zimawonjezera moyo wake ndi kulimba. Kuphatikiza apo, zida zokhala ndi matenthedwe owongolera amawunikidwa kuti ziwongolere kuthekera kwa FPC kutulutsa kutentha kuti igwire bwino ntchito pakutentha kwambiri.

Chitukuko china chamtsogolo ndikupita patsogolo kwaukadaulo wapamwamba wokutira.Njira zatsopano zokutira zikupangidwa kuti zipereke chithunzithunzi cholondola komanso chofananira pa FPC. Njira monga Atomic Layer Deposition (ALD) ndi Plasma Enhanced Chemical Vapor Deposition (PECVD) zimalola kuwongolera bwino kwa makulidwe a zokutira ndi kapangidwe kake, zomwe zimapangitsa kuti pakhale kusungunuka komanso kumamatira. Matekinoloje apamwamba okutira awa alinso ndi kuthekera kochepetsera kusinthasintha kwa njira ndikuwongolera magwiridwe antchito onse.

Kuonjezera apo, pali kutsindika kowonjezereka pa njira zothetsera chithandizo chapamwamba pa chilengedwe.Pokhala ndi malamulo ochulukirachulukira komanso nkhawa zokhudzana ndi chilengedwe cha njira zachikhalidwe zokonzekera pamwamba, ofufuza akufufuza njira zina zotetezeka komanso zokhazikika. Mwachitsanzo, zokutira zokhala ndi madzi zikutchuka chifukwa cha mpweya wake wochepa wa volatile organic compound (VOC) poyerekeza ndi zokutira zosungunulira. Kuphatikiza apo, kuyesayesa kukuchitika kuti akhazikitse njira zokondera zachilengedwe zomwe sizipanga zinthu zapoizoni kapena zinyalala.

Powombetsa mkota,njira yothandizira pamwamba imakhala ndi gawo lofunika kwambiri powonetsetsa kudalirika ndi ntchito ya bolodi yofewa ya FPC. Pomvetsetsa kufunika kokonzekera pamwamba ndikusankha njira yoyenera, opanga amatha kupanga maulendo apamwamba osinthika omwe amakwaniritsa zofunikira za mafakitale osiyanasiyana. Kukhazikitsa njira zochiritsira zam'mwamba, kuyesa kuwongolera bwino, ndikuthana bwino ndi zovuta zazachipatala kumathandizira kuti ma PCB osinthika a FPC apambane pamsika.

Nthawi yotumiza: Sep-08-2023

Kubwerera