HDI (High Density Interconnect) ma PCB olimba-flex amayimira pachimake chaukadaulo wotsogola wa board board, kuphatikiza ubwino wa mawaya amphamvu kwambiri komanso kusinthasintha kwa matabwa olimba.Nkhaniyi ikufuna kufotokozera njira yopangira HDI yokhazikika-flex PCB ndikupereka zidziwitso zamtengo wapatali pamapangidwe ake, zipangizo ndi njira zazikulu zopangira.Pomvetsetsa zovuta zomwe zikukhudzidwa, mainjiniya ndi opanga amatha kukulitsa mapangidwe awo ndikuthandizana bwino ndi opanga kuti asinthe malingaliro awo apamwamba kukhala owona.

1.MvetsetsaniHDI yokhazikika yosinthika PCB:

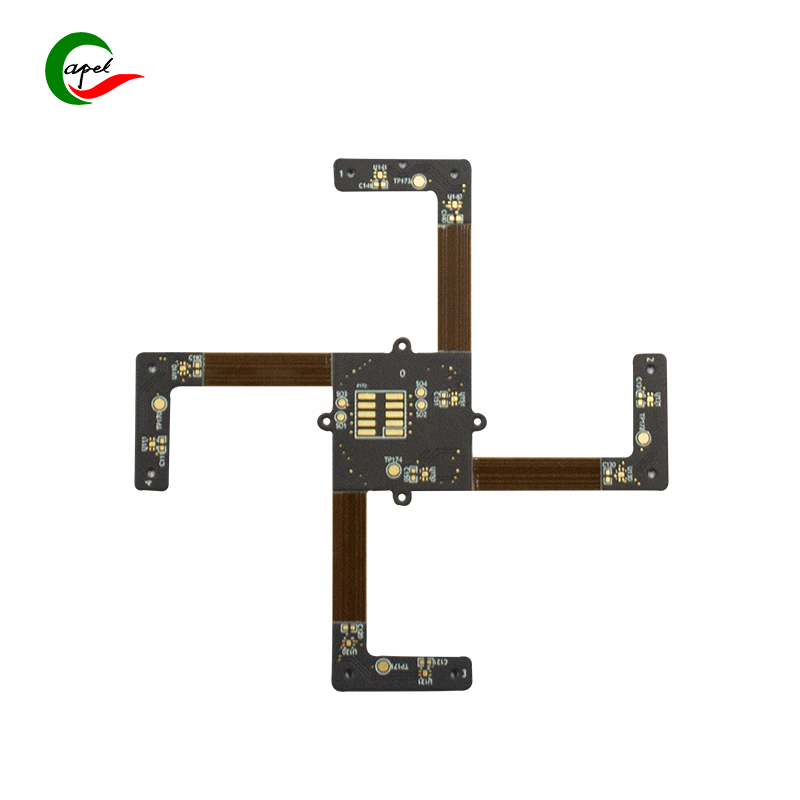

HDI (High Density Interconnect) rigid-flex PCB ndi mawonekedwe apamwamba a bolodi yosindikizidwa yomwe imaphatikiza ubwino wa kulumikizana kwapamwamba komanso kusinthasintha.Kuphatikizana kwapadera kumeneku kumawapangitsa kukhala oyenera kukwaniritsa zofunikira za zipangizo zamakono zamakono.

Kulumikizana kwakukulu kumatanthawuza kukwanitsa kukwaniritsa zigawo zazikuluzikulu ndi njira zowonetsera mkati mwa malo ochepa a bolodi.Pomwe kufunikira kwa zida zazing'ono, zophatikizika zikupitilira kukula, ukadaulo wa HDI umathandizira kupanga ndi kupanga mabwalo ovuta muzinthu zazing'ono. Kuchulukirachulukira kolumikizana kumapangitsa kuti magwiridwe antchito ambiri agwirizane ndi zida zazing'ono, zomwe zimapangitsa kuti zikhale zogwira mtima komanso zamphamvu.

Kusinthasintha ndi chinthu china chofunikira cha HDI rigid-flex PCBs. Kusinthasintha kumeneku kumapangitsa bolodi kukhala yopindika, kupindika kapena kupindika popanda kusokoneza magwiridwe antchito kapena kudalirika.Kusinthasintha kumakhala kopindulitsa makamaka pazida zamagetsi zomwe zimafunikira mawonekedwe owoneka bwino kapena zomwe zimafunika kupirira kugwedezeka, kugwedezeka, kapena malo owopsa. Zimathandizanso kusakanikirana kosasunthika kwa zida zamagetsi kuchokera kumagulu osiyanasiyana a bolodi, kuchotsa kufunikira kowonjezera zowonjezera kapena zingwe.

Kugwiritsa ntchito ukadaulo wa HDI kumapereka maubwino angapo.Choyamba, imathandizira kwambiri kukhulupirika kwa ma siginecha pochepetsa mtunda pakati pa zigawo ndi zolumikizira, kuchepetsa kutayika kwa ma sign, crosstalk ndi kusokoneza ma elekitiroma. Izi zimakulitsa magwiridwe antchito komanso kudalirika pamapulogalamu othamanga kwambiri a digito ndi RF. Kachiwiri, HDI okhwima-flex PCB akhoza kwambiri kuchepetsa kukula wonse ndi kulemera kwa zipangizo zamagetsi. Ukadaulo wa HDI umachotsa kufunikira kowonjezera zolumikizira, zingwe, ndi kulumikizana ndi board-to-board, kulola kuti pakhale mapangidwe ophatikizika, opepuka. Izi ndizofunikira makamaka kwa mafakitale monga zamlengalenga ndi zamagetsi zonyamula anthu, komwe kupulumutsa kulemera ndi malo ndikofunikira. Kuphatikiza apo, ukadaulo wa HDI umapangitsanso kudalirika kwa zida zamagetsi. Mwa kuchepetsa chiwerengero cha interconnects, HDI okhwima-flex PCBs kuchepetsa chiopsezo kulephera chifukwa lotayirira malumikizidwe kapena solder olowa kutopa. Izi zimathandizira kukhazikika kwazinthu ndikuwonjezera kudalirika kwanthawi yayitali.

Mapulogalamu a HDI okhwima-flex amapezeka m'mafakitale osiyanasiyana, kuphatikizapo ndege, zipangizo zamankhwala, mauthenga a telefoni ndi zamagetsi ogula.M'makampani opanga ndege, ma PCB olimba a HDI amagwiritsidwa ntchito poyendetsa ndege, ma avionics, ndi njira zoyankhulirana chifukwa cha kukula kwake, kulemera kwake, komanso kutha kupirira mikhalidwe yovuta. M'zachipatala, amagwiritsidwa ntchito pazida monga makina opangira pacemaker, makina ojambulira achipatala, ndi zida zojambulidwa. Matelefoni ndi zamagetsi ogula amapindula ndi kukula kocheperako komanso kupititsa patsogolo magwiridwe antchito a HDI rigid-flex PCBs mu mafoni a m'manja, mapiritsi, zovala, ndi zida zina zonyamula.

2.HDI yokhazikika-yosinthika PCB kupanga njira: pang'onopang'ono

A. Kupanga zolepheretsa ndikukonzekera mafayilo a CAD:

Gawo loyamba la HDI lokhazikika-flex PCB kupanga ndondomeko ndi kuganizira zopinga mapangidwe ndi kukonzekera CAD owona. Zolepheretsa kamangidwe zimakhala ndi gawo lofunikira pakuzindikiritsa magwiridwe antchito a PCB, kudalirika, ndi kupangidwa. Zoletsa zina zofunika kuziganizira ndi izi:

Kuchepetsa Kukula:

Kukula kwa PCB kumadalira zofunikira za chipangizo chomwe chimagwiritsidwa ntchito. Ndikofunikira kuonetsetsa kuti PCB ikugwirizana ndi malo osankhidwa popanda kukhudza magwiridwe antchito kapena kudalirika.

Kudalirika:

Mapangidwe a PCB akuyenera kukhala odalirika komanso otha kupirira zomwe zikuyembekezeka. Zinthu monga kutentha, chinyezi, kugwedezeka ndi kupsinjika kwamakina ziyenera kuganiziridwa pakupanga mapangidwe.

Signal Integrity:

Mapangidwe amayenera kuganizira kukhulupirika kwa ma sign kuti achepetse chiwopsezo cha kutsika kwa ma sign, phokoso, kapena kusokonezedwa. Ma siginecha othamanga kwambiri a digito ndi ma RF amafunikira kuwongolera mosamalitsa komanso kuwongolera koletsa.

Kasamalidwe ka Kutentha:

Kuwongolera kutentha ndikofunikira kuti tipewe kutenthedwa komanso kuonetsetsa kuti zida zamagetsi zikuyenda bwino. Kutaya kwa kutentha kungathe kutheka kudzera mu kuyika koyenera kwa njira zotenthetsera, zoyatsira kutentha, ndi mapepala otentha. Mapulogalamu a CAD amagwiritsidwa ntchito kupanga mafayilo a masanjidwe a PCB. Amalola opanga kutanthauzira masanjidwe osanjikiza, kuyika kwa zigawo ndi njira zotsata zamkuwa. Mapulogalamu a CAD amapereka zida ndi luso loyimira bwino ndikuwona zojambula, zomwe zimapangitsa kuti zikhale zosavuta kuzindikira ndi kukonza mavuto omwe angakhalepo asanapangidwe.

B. Kusankha Zinthu ndi Mapangidwe Osanjikiza:

Pambuyo pokonzekera mafayilo a CAD, sitepe yotsatira ndikusankha zinthu ndi kupanga mapangidwe. Kusankha zida zoyenera ndikofunikira pakuwonetsetsa kuti ma PCB okhazikika a HDI amakwaniritsa magwiridwe antchito amagetsi, kasamalidwe kamafuta, komanso kukhulupirika kwamakina. Zida zosanjikiza zolimba, monga FR-4 kapena ma laminates apamwamba, zimapereka chithandizo chamakina ndi kukhazikika. Wosanjikiza wosinthika nthawi zambiri amapangidwa ndi filimu ya polyimide kapena polyester kuti azitha kusinthasintha komanso kukhazikika. Njira yopangira ma stackup imaphatikizapo kudziwa kakonzedwe ka magawo osiyanasiyana, kuphatikiza zigawo zolimba komanso zosinthika, makulidwe amkuwa, ndi zida za dielectric. Mapangidwe a stackup akuyenera kuganizira zinthu monga kukhulupirika kwa ma sign, control impedance, ndi kugawa mphamvu. Kuyika kosanjikiza koyenera komanso kusankha kwazinthu kumathandizira kuwonetsetsa kuti ma siginecha akuyenda bwino, kuchepetsa crosstalk ndikupereka kusinthasintha kofunikira.

C. Kubowola kwa laser ndi kupanga microhole:

Kubowola kwa laser ndi gawo lofunika kwambiri popanga ma microvia oyenda kwambiri mu HDI PCBs. Ma Microvias ndi mabowo ang'onoang'ono omwe amagwiritsidwa ntchito kulumikiza zigawo zosiyanasiyana za PCB, zomwe zimapangitsa kuti pakhale kulumikizana kwakukulu. Kubowola kwa laser kumapereka maubwino angapo kuposa njira zamakina zamakina. Zimalola kuti tibowo tating'ono ting'onoting'ono, zomwe zimapangitsa kuti pakhale kachulukidwe kanjira komanso mapangidwe ophatikizika. Kubowola kwa laser kumaperekanso kulondola kwambiri komanso kuwongolera, kuchepetsa chiopsezo cha kusalongosoka kapena kuwonongeka kwa zinthu zozungulira. Pobowola laser, mtengo wa laser wolunjika umagwiritsidwa ntchito kutulutsa zinthu, kupanga mabowo ang'onoang'ono. Mabowowo amapangidwa ndi zitsulo kuti apereke madulidwe pakati pa zigawo, kulola kufalitsa bwino kwa zizindikiro.

D. Chemical copper plating:

Electroless copper plating ndi sitepe yofunika kwambiri popanga HDI rigid-flex board. Njirayi imaphatikizapo kuyika kagawo kakang'ono ka mkuwa mkati mwa ma micropores ndi pamwamba pa PCB. Kufunika kwa electroless copper plating kwagona pakutha kwake kutsimikizira kulumikizana kodalirika kwamagetsi komanso kutumizirana ma sign abwino. Chosanjikiza chamkuwa chimadzaza ma microvias ndikulumikiza magawo osiyanasiyana a PCB, ndikupanga njira yoyendetsera ma sigino. Komanso amapereka pamwamba solderable kwa chigawo ubwenzi. Njira yopangira mkuwa yopanda ma electroless imaphatikizapo masitepe angapo, kuphatikiza kukonzekera pamwamba, kuyambitsa ndi kuyika. PCB imatsukidwa koyamba ndikuyatsidwa kuti ilimbikitse kumamatira. Mankhwalawa amagwiritsidwa ntchito poyika njira yomwe ili ndi ayoni amkuwa pamwamba pa PCB, ndikuyika mkuwa wochepa thupi.

E. Kutumiza Zithunzi ndi Lithography:

Kutumiza zithunzi ndi kujambula zithunzi ndi zigawo za HDI yokhazikika-flex PCB kupanga ndondomeko. Masitepewa akuphatikiza kugwiritsa ntchito chithunzithunzi kupanga mawonekedwe ozungulira pa PCB ndikuwunikira kuwala kwa UV kudzera pazithunzi zojambulidwa. Pa chithunzi kutengerapo ndondomeko, photoresist zakuthupi ntchito pamwamba PCB. Zida za Photoresist zimakhudzidwa ndi kuwala kwa UV ndipo zimatha kuwululidwa mwa kusankha. PCB imalumikizidwa ndi chithunzithunzi chazithunzi ndipo kuwala kwa UV kumadutsa m'malo omveka bwino a Photomask kuti awonetse wojambulayo. Pambuyo powonekera, PCB imapangidwa kuti ichotse chithunzithunzi chosawoneka bwino, kusiya mawonekedwe ofunikira adera. Zitsanzozi zimagwira ntchito ngati zigawo zotetezera muzochitika zotsatila. Kupanga mawonekedwe ozungulira, ma etching mankhwala amagwiritsidwa ntchito kuchotsa mkuwa wosafunikira. Madera osaphimbidwa ndi photoresist amawululidwa ndi etchant, yomwe imachotsa mkuwa, ndikusiya njira zomwe mukufuna.

F. Etching ndi electroplating process:

Cholinga cha etching ndikuchotsa mkuwa wochulukirapo ndikupanga mawonekedwe ozungulira pa HDI rigid-flex PCB. Etching imaphatikizapo kugwiritsa ntchito etchant, nthawi zambiri asidi kapena mankhwala, kuchotsa mkuwa wosafunikira. Etching imayendetsedwa ndi chitetezo cha photoresist wosanjikiza chomwe chimalepheretsa etchant kuukira mayendedwe ofunikira. Mosamala yang'anirani nthawi ndi kuchuluka kwa mawu kuti mukwaniritse m'lifupi ndi kuya kwake komwe mukufuna. Pambuyo pa etching, photoresist yotsalayo imavulidwa kuti iwonetsere zozungulira. Njira yochotseramo imaphatikizapo kugwiritsa ntchito zosungunulira kuti zisungunuke ndi kuchotsa photoresist, ndikusiya maulendo ozungulira bwino komanso omveka bwino. Kuti muwonjezere mayendedwe ozungulira ndikuwonetsetsa kuti ma conductivity akuyenda bwino, njira yopumira imafunika. Izi zimaphatikizapo kuyika gawo lina la mkuwa pamayendedwe ozungulira kudzera pa electroplating kapena electroless plating process. Makulidwe ndi kufanana kwa plating yamkuwa ndizofunikira kwambiri kuti mukwaniritse kulumikizana kodalirika kwamagetsi.

G. Solder chigoba ntchito ndi chigawo chimodzi:

Kugwiritsa ntchito chigoba cha solder ndi kusonkhanitsa zigawo ndi njira zofunika kwambiri pakupanga HDI yokhazikika-flex PCB. Gwiritsani ntchito chigoba cha solder kuti muteteze mikwingwirima yamkuwa ndikupereka zotsekemera pakati pawo. Solder chigoba amapanga wosanjikiza zoteteza pamwamba lonse PCB pamwamba, kupatula madera amene amafuna soldering, monga chigawo ziyangoyango ndi vias. Izi zimathandiza kupewa bridge yogulitsa ndi akabudula panthawi ya msonkhano. Kuphatikiza kwazinthu kumaphatikizapo kuyika zida zamagetsi pa PCB ndikuzigulitsa m'malo mwake. Zigawo zimayikidwa bwino ndikugwirizanitsa ndi potera kuti zitsimikizire kuti magetsi akugwirizana bwino. Gwiritsani ntchito njira za soldering monga reflow kapena wave soldering kutengera mtundu wa chigawocho ndi zofunikira za msonkhano. The reflow soldering ndondomeko imaphatikizapo kutenthetsa PCB kutentha kwapadera komwe kumapangitsa kuti solder isungunuke ndikupanga mgwirizano wokhazikika pakati pa chigawo chotsogolera ndi mapepala a PCB. Wave soldering nthawi zambiri amagwiritsidwa ntchito popanga zida zapabowo, pomwe PCB imadutsa pamafunde a solder wosungunuka kuti apange kulumikizana.

H. Kuyesa ndi Kuwongolera Ubwino:

Gawo lomaliza la HDI lokhazikika-flex PCB kupanga ndondomeko ndi kuyesa ndi kulamulira khalidwe. Kuyesa mwamphamvu ndikofunikira kuti muwonetsetse kuti PCB imagwira ntchito, yodalirika komanso yogwira ntchito. Yesani mayeso amagetsi kuti muwone zazifupi, zotseguka, ndi kupitiliza. Izi zimaphatikizapo kugwiritsa ntchito ma voltages ndi mafunde apadera ku PCB ndikuyesa kuyankha pogwiritsa ntchito zida zoyeserera zokha. Kuyang'ana kowoneka kumachitidwanso kuti atsimikizire mtundu wa solder, kuyika kwa gawo, komanso ukhondo wonse wa PCB. Zimathandizira kuzindikira zolakwika zilizonse zomwe zingakhalepo monga zida zosalongosoka, milatho ya solder, kapena zoipitsa. Kuphatikiza apo, kuwunika kwapang'onopang'ono kwapang'onopang'ono kutha kuchitidwa kuti muwone kuthekera kwa PCB kupirira kutentha kwa njinga kapena kugwedezeka kwamafuta. Izi ndizofunikira makamaka pamapulogalamu omwe PCB imakumana ndi kusintha kwa kutentha kwambiri. Pa nthawi ndi pambuyo pa sitepe iliyonse ya kupanga, njira zoyendetsera khalidwe zimayendetsedwa kuti zitsimikizire kuti PCB ikukwaniritsa zofunikira ndi zofunikira. Izi zikuphatikizapo kuyang'anira ndondomeko za ndondomeko, kuyendetsa ndondomeko ya statistical process (SPC), ndi kuchita kafukufuku wanthawi ndi nthawi kuti azindikire ndi kukonza zolakwika zilizonse.

3.Mavuto omwe amakumana nawo popanga matabwa a HDI okhwima:

Kupanga matabwa a HDI okhwima-flex kumapereka zovuta ndi zovuta zomwe ziyenera kuyang'aniridwa mosamala kuti zitsimikizidwe kuti mapeto ali apamwamba kwambiri.Mavutowa akuzungulira mbali zitatu zazikuluzikulu: kuyanjanitsa bwino, zolakwika zapamtunda, ndi kusintha kwa impedance panthawi ya lamination.

Kuyanjanitsa kolondola ndikofunikira pama board a HDI okhazikika chifukwa amaphatikiza zigawo zingapo ndi zida zomwe ziyenera kuyikidwa bwino. Kukwaniritsa kulondola bwino kumafuna kusamala mosamala ndikuyika magawo osiyanasiyana kuonetsetsa kuti vias ndi zigawo zina zikugwirizana bwino. Kusokoneza kulikonse kungayambitse mavuto aakulu monga kutaya chizindikiro, zazifupi, kapena kupuma. Opanga amayenera kuyika ndalama pazida zapamwamba komanso ukadaulo kuti awonetsetse kuti zikuyenda bwino munthawi yonseyi.

Kupeŵa zofooka zapamtunda ndi vuto lina lalikulu. Panthawi yopangira zinthu, zolakwika zapamtunda monga zokwapula, zowonongeka, kapena zowonongeka zimatha kuchitika, zomwe zimakhudza ntchito ndi kudalirika kwa matabwa a HDI okhwima.Zolakwika izi zimatha kusokoneza kulumikizana kwa magetsi, kusokoneza kukhulupirika kwa ma sign, kapena kupangitsa kuti bolodi ilephere palimodzi. Pofuna kupewa zolakwika zapamtunda, njira zowongolera bwino ziyenera kuchitidwa, kuphatikiza kusamala, kuyang'anira nthawi zonse, komanso kugwiritsa ntchito malo aukhondo panthawi yopanga.

Kuchepetsa kusintha kwa impedance panthawi ya lamination ndikofunikira kuti magetsi a HDI azigwira bwino ntchito.Lamination imaphatikizapo kugwiritsa ntchito kutentha ndi kukakamiza kulumikiza zigawo zosiyanasiyana pamodzi. Komabe, njirayi ingayambitse kusintha kwa dielectric mosasinthasintha ndi kondakitala m'lifupi, kuchititsa kusintha osafunika impedance. Kuwongolera njira yopangira lamination kuti muchepetse kusinthaku kumafuna kuwongolera bwino kutentha, kupanikizika, ndi nthawi, komanso kutsatira mosamalitsa zomwe zidapangidwa. Kuphatikiza apo, njira zapamwamba zoyesera ndi zotsimikizira zitha kugwiritsidwa ntchito kuti zitsimikizire kuti zopinga zomwe zikufunika zikusungidwa.

Kuthana ndi zovuta izi popanga HDI flex board kumafuna kuti opanga ndi opanga azigwira ntchito limodzi munthawi yonseyi.Okonza ayenera kuganizira mozama zolepheretsa kupanga ndikuzidziwitsa bwino kwa opanga. Kumbali inayi, opanga ayenera kumvetsetsa zofunikira ndi zopinga kuti agwiritse ntchito njira yoyenera yopangira. Kugwirizana kumathandizira kuthana ndi zovuta zomwe zingachitike kumayambiriro kwa kamangidwe ndikuwonetsetsa kuti njira yopangira imakongoletsedwa ndi ma board apamwamba a HDI okhazikika.

Pomaliza:

Njira yopangira HDI yolimba-flex PCB ndi njira zovuta koma zovuta zomwe zimafuna luso laukadaulo, lolondola komanso lodalirika.Kumvetsetsa gawo lililonse la ntchitoyi kumathandizira Capel kukulitsa luso lawo lopereka zinthu zabwino kwambiri pakanthawi kochepa. Poika patsogolo zoyeserera zogwirira ntchito, zodzipangira zokha komanso kuwongolera njira mosalekeza, Capel imatha kukhala patsogolo pakupanga HDI yokhazikika-flex PCB ndikukwaniritsa kufunikira kokulira kwa ma board omwe amagwira ntchito zambiri komanso apamwamba m'mafakitale.

Nthawi yotumiza: Sep-15-2023

Kubwerera