Pakupanga zamagetsi, msonkhano waukadaulo waukadaulo (SMT) ndi imodzi mwazinthu zofunika kwambiri pakupangira bwino zida zamagetsi.Msonkhano wa SMT umagwira ntchito yofunika kwambiri pazabwino zonse, kudalirika komanso mphamvu zamagetsi zamagetsi. Pofuna kukuthandizani kuti mumvetse bwino komanso kuti mudziwe bwino msonkhano wa PCB, Capel ikutsogolerani kuti mufufuze zofunikira za SMT refactoring. ndikukambirana chifukwa chake kuli kofunika kwambiri popanga zamagetsi.

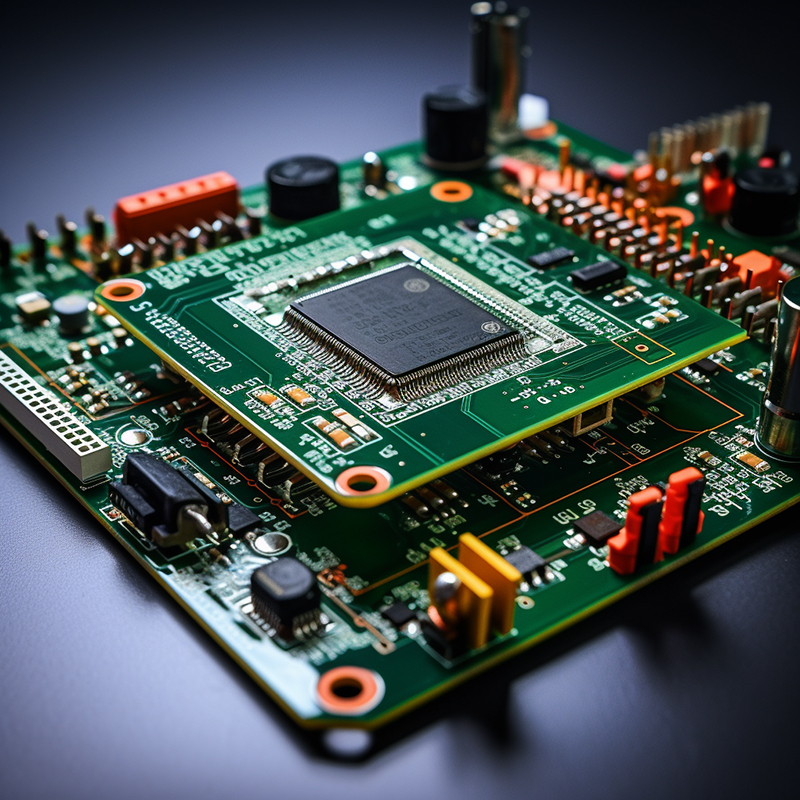

Msonkhano wa SMT, womwe umadziwikanso kuti surface mount assembly, ndi njira yokhazikitsira zida zamagetsi pamwamba pa bolodi losindikizidwa (PCB).Mosiyana ndi ukadaulo wamabowo (THT), womwe umayika zida kudzera m'mabowo mu PCB, msonkhano wa SMT umaphatikizapo kuyika zida pamwamba pa bolodi. M'zaka zaposachedwa, ukadaulo uwu watchuka kwambiri chifukwa cha zabwino zake zambiri kuposa THT, monga kuchuluka kwa zigawo, kukula kwa bolodi yaying'ono, kukhulupirika kwa ma siginecha, komanso kuchuluka kwa liwiro lopanga.

Tsopano, tiyeni tifufuze zoyambira za SMT Assembly.

1. Kuyika kwazinthu:Gawo loyamba la msonkhano wa SMT limakhudza kuyika bwino kwa zida zamagetsi pa PCB. Izi nthawi zambiri zimachitika pogwiritsa ntchito makina osankha ndi malo omwe amangosankha zinthu kuchokera ku feeder ndikuziyika molondola pa bolodi. Kuyika koyenera kwa zigawo ndizofunikira kuti zitsimikizidwe kuti zikugwira ntchito moyenera komanso kudalirika kwa zida zamagetsi.

2. Ntchito ya solder paste:Pambuyo kukwera zigawo zikuluzikulu, ntchito solder phala (kusakaniza solder particles ndi flux) kuti ziyangoyango za PCB. Phala la solder limagwira ntchito ngati zomatira kwakanthawi, kugwirizira zigawo m'malo mwake zisanachitike. Zimathandizanso kupanga kugwirizana kwamagetsi pakati pa chigawocho ndi PCB.

3. Reflow soldering:Gawo lotsatira mu msonkhano wa SMT ndi reflow soldering. Izi zimaphatikizapo kutentha kwa PCB m'njira yoyendetsedwa kuti isungunuke phala la solder ndikupanga cholumikizira chokhazikika. Reflow soldering itha kuchitidwa pogwiritsa ntchito njira zosiyanasiyana monga convection, radiation ya infrared kapena gawo la nthunzi. Panthawiyi, phala la solder limasintha kukhala losungunuka, limayenda pazitsulo zamagulu ndi mapepala a PCB, ndipo limalimba kuti likhale logwirizana kwambiri ndi solder.

4. Kuyang'anira ndi kuwongolera khalidwe:Pambuyo pa soldering ndondomeko yatha, PCB idzadutsa poyang'anitsitsa mosamalitsa ndi kuwongolera khalidwe kuti zitsimikizire kuti zigawo zonse zaikidwa bwino ndi zolumikizira zogulitsira ndi zapamwamba kwambiri. Njira zowunikira modzidzimutsa (AOI) ndi njira zowunikira ma X-ray nthawi zambiri zimagwiritsidwa ntchito kuti zizindikire zolakwika zilizonse kapena zolakwika pakuphatikiza. Kusagwirizana kulikonse komwe kumapezeka pakuwunika kumakonzedwa PCB isanapite ku gawo lotsatira la kupanga.

Ndiye, chifukwa chiyani msonkhano wa SMT ndi wofunikira kwambiri pakupanga zamagetsi?

1. Kutsika mtengo:Msonkhano wa SMT uli ndi phindu lamtengo wapatali kuposa THT chifukwa umachepetsa nthawi yonse yopanga ndikufewetsa njira yopangira. Kugwiritsiridwa ntchito kwa zipangizo zamakina pakuyika chigawo ndi soldering kumapangitsa kuti pakhale zokolola zambiri komanso kuchepetsa ndalama zogwirira ntchito, zomwe zimapangitsa kukhala njira yabwino kwambiri yopangira ndalama zambiri.

2. Miniaturization:Chitukuko cha zida zamagetsi ndi zida zazing'ono komanso zophatikizika. Msonkhano wa SMT umathandizira kuti pakhale miniaturization yamagetsi pakuyika zida zokhala ndi phazi laling'ono. Izi sizimangowonjezera kusuntha, komanso zimatsegula mwayi wopangira zatsopano kwa opanga zinthu.

3. Kuchita bwino:Popeza zigawo za SMT zimayikidwa mwachindunji pa PCB pamwamba, njira zazifupi zamagetsi zimalola kukhulupirika kwa chizindikiro ndikupititsa patsogolo ntchito ya zipangizo zamagetsi. Kuchepetsa mphamvu ya parasitic ndi inductance kumachepetsa kutayika kwa ma sign, crosstalk ndi phokoso, kukonza magwiridwe antchito.

4. Kachulukidwe kagawo kakang'ono:Poyerekeza ndi THT, msonkhano wa SMT ukhoza kukwaniritsa kachulukidwe kazinthu zambiri pa PCB. Izi zikutanthauza kuti ntchito zambiri zikhoza kuphatikizidwa mu malo ang'onoang'ono, zomwe zimathandiza kuti pakhale zipangizo zamagetsi zovuta komanso zowonjezera. Izi ndizofunikira makamaka m'mafakitale omwe malo nthawi zambiri amakhala ochepa, monga mafoni am'manja, zamagetsi zamagetsi, ndi zida zamankhwala.

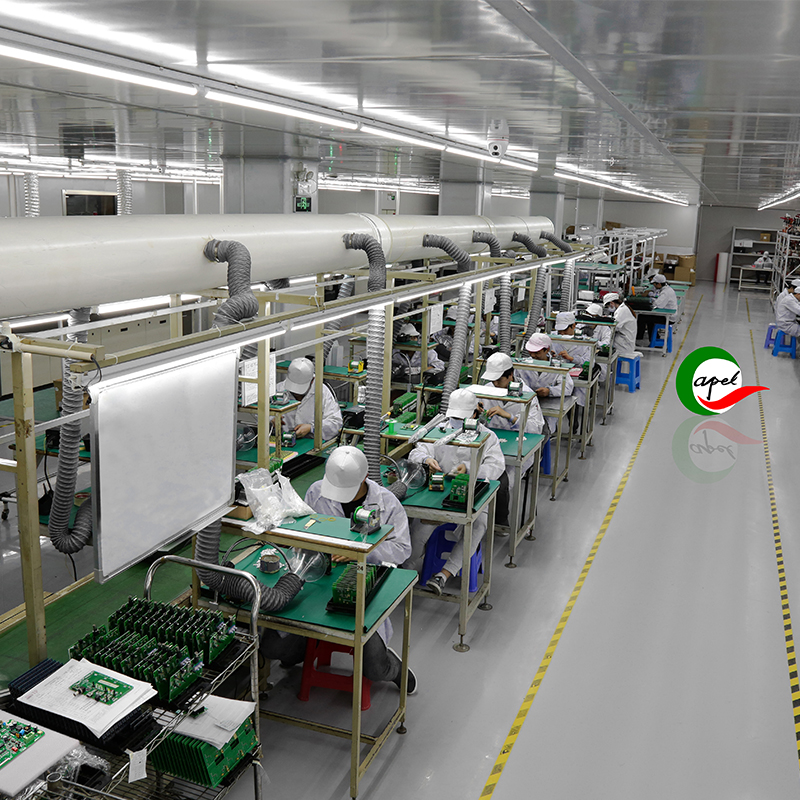

Kutengera kusanthula pamwambapa,kumvetsetsa zoyambira za msonkhano wa SMT ndikofunikira kwa aliyense amene akuchita nawo kupanga zamagetsi. Msonkhano wa SMT umapereka maubwino ambiri kuposa ukadaulo wamabowo, kuphatikiza kugwiritsa ntchito ndalama, luso laling'ono, magwiridwe antchito, komanso kachulukidwe kagawo kakang'ono. Pamene kufunikira kwa zipangizo zamagetsi zing'onozing'ono, zofulumira, komanso zodalirika zikukulirakulirabe, msonkhano wa SMT udzakhala ndi gawo lofunika kwambiri pokwaniritsa zofunikirazi.Shenzhen Capel Technology Co., Ltd. ili ndi fakitale yake ya PCB ndipo yakhala ikupereka ntchitoyi kuyambira 2009. Ndi zaka 15 za ntchito yolemera, kuyenda molimbika, luso labwino kwambiri, zipangizo zamakono zopangira makina, makina oyendetsa bwino, ndi Capel gulu akatswiri akatswiri kupereka makasitomala padziko lonse mwatsatanetsatane mkulu, apamwamba kutembenukira mwamsanga PCB Assemble prototyping. Mankhwalawa akuphatikizapo msonkhano wa PCB wosinthika, msonkhano wokhazikika wa PCB, msonkhano wa PCB wosasunthika, msonkhano wa HDI PCB, msonkhano wa PCB wapamwamba kwambiri ndi msonkhano wapadera wa PCB. Ntchito zathu zomvera zogulitsa zisanachitike komanso zotsatsa pambuyo pogulitsa komanso kutumiza munthawi yake kumathandizira makasitomala athu kutenga mwayi wamsika wama projekiti awo.

Nthawi yotumiza: Aug-24-2023

Kubwerera