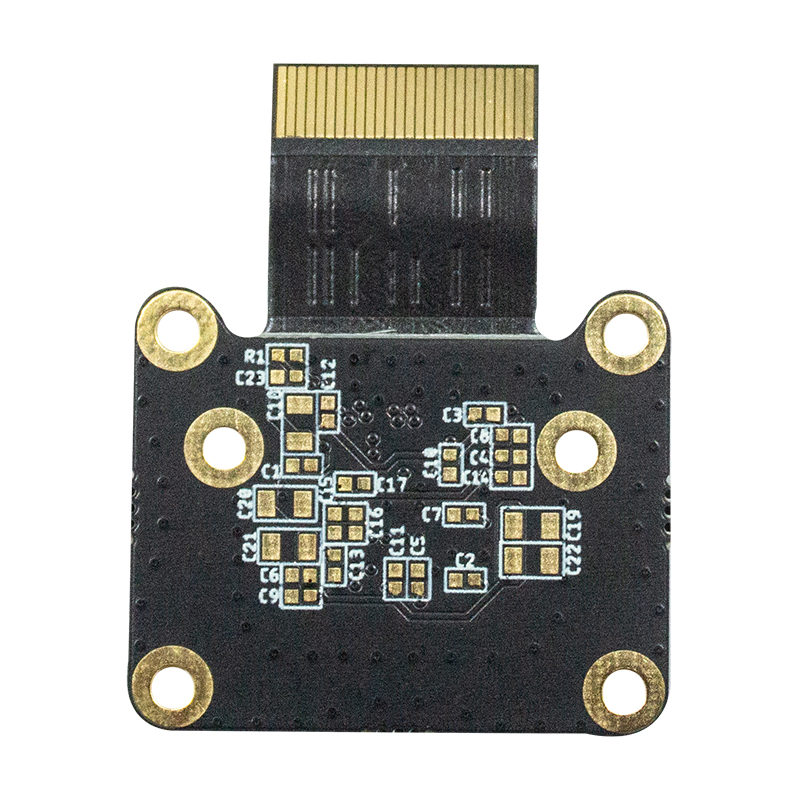

PCB (Printed Circuit Board) ndi gawo lofunika kwambiri muzinthu zamakono zamakono, zomwe zimathandiza kugwirizanitsa ndi ntchito zamagulu osiyanasiyana amagetsi. Njira yopangira PCB imaphatikizapo njira zingapo zofunika, imodzi mwazo ndikuyika mkuwa pagawo. Nkhaniyi tiwona njira zoyika mkuwa pagawo la PCB panthawi yopanga, ndikuwunika njira zosiyanasiyana zomwe zimagwiritsidwa ntchito, monga electroless copper plating ndi electroplating.

1. Electroless copper plating: kufotokoza, ndondomeko ya mankhwala, ubwino, kuipa ndi malo ogwiritsira ntchito.

Kuti mumvetse zomwe electroless copper plating ndi, ndikofunikira kumvetsetsa momwe zimagwirira ntchito. Mosiyana ndi electrodeposition, yomwe imadalira magetsi poyika zitsulo, electroless copper plating ndi njira ya autophoretic. Zimaphatikizapo kuchepetsa kuchepetsedwa kwa mankhwala a ayoni amkuwa pagawo laling'ono, zomwe zimapangitsa kuti pakhale mkuwa wofanana kwambiri komanso wofanana.

Yeretsani gawo lapansi:Tsukani bwino gawo lapansili kuti muchotse zonyansa zilizonse kapena ma oxide omwe angalepheretse kumamatira. Kutsegula: Njira yothetsera yomwe ili ndi chothandizira zitsulo zamtengo wapatali monga palladium kapena platinamu imagwiritsidwa ntchito poyambitsa njira yopangira electroplating. Njira yothetsera vutoli imathandizira kuyika kwa mkuwa pa gawo lapansi.

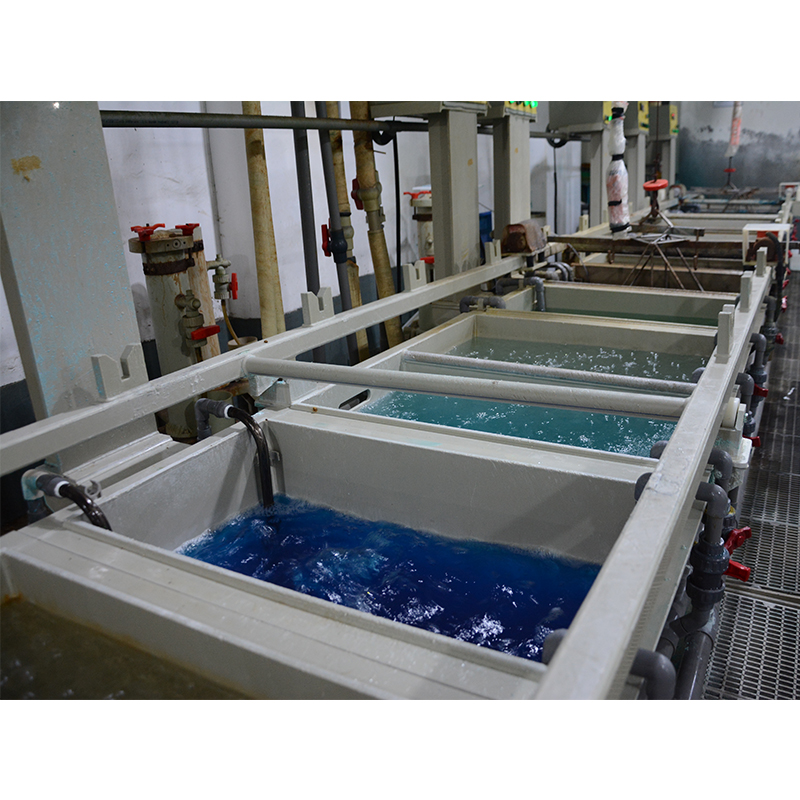

Imirira mu plating solution:Miwiritsani gawo lapansi lomwe lidalowetsedwa muzitsulo zopanda ma electro-copper plating solution. Yankho la plating lili ndi ma ion amkuwa, othandizira kuchepetsa ndi zowonjezera zosiyanasiyana zomwe zimayang'anira ntchito yoyika.

Njira ya Electroplating:Njira yochepetsera mu njira ya electroplating imachepetsa ayoni amkuwa kukhala maatomu amkuwa amkuwa. Kenako maatomu amenewa amalumikizana ndi pamwamba pake, n’kupanga kusanjika kosalekeza ndi kofanana kwa mkuwa.

Muzimutsuka ndi kuumitsa:Kuchuluka kwa mkuwa komwe kumafunidwa kukwaniritsidwa, gawo lapansi limachotsedwa mu thanki yoyikapo ndikutsukidwa bwino kuti muchotse mankhwala aliwonse otsalira. Yamitsani gawo lapansi lopukutidwa musanayambe kukonza. Chemical copper plating process Kapangidwe kakemidwe ka plating kopanda ma electroless mkuwa kumakhudzanso kusintha kwa redox pakati pa ma ion amkuwa ndi zochepetsera. Mfundo zazikuluzikulu pakuchitapo kanthu ndi izi: Kutsegula: Kugwiritsa ntchito zida zachitsulo zolemekezeka monga palladium kapena platinamu kuti atsegule gawo lapansi. Chothandizira chimapereka malo ofunikira kuti agwirizane ndi ma ion amkuwa.

Wochepetsa:The kuchepetsa wothandizila mu plating njira (nthawi zambiri formaldehyde kapena sodium hypophosphite) amayambitsa kuchepetsa. Ma reagents awa amapereka ma elekitironi ku ayoni amkuwa, kuwasandutsa maatomu amkuwa amkuwa.

Autocatalytic reaction:Ma atomu amkuwa opangidwa ndi kuchepetsa zomwe amachita amachitira ndi chothandizira padziko lapansi kuti apange wosanjikiza wamkuwa wofanana. Zomwe zimachitika zimapitilira popanda kufunikira kwa magetsi ogwiritsidwa ntchito kunja, ndikupangitsa kukhala "electroless plating."

Kuwongolera kwa mtengo:Mapangidwe ndi kuyika kwa yankho la plating, komanso magawo opangira zinthu monga kutentha ndi pH, amawunikidwa mosamala kuti awonetsetse kuti kuchuluka kwa zoyikapo kumayendetsedwa komanso yunifolomu.

Ubwino wa electroless copper plating Uniformity:Electroless copper plating imakhala yofanana kwambiri, kuonetsetsa makulidwe a yunifolomu m'mawonekedwe ovuta komanso malo okhazikika. Conformal Coating: Izi zimapereka zokutira zofananira zomwe zimamatira bwino magawo osagwirizana ndi geometrically monga ma PCB. Kumamatira kwabwino: Kuyika kwa mkuwa kopanda magetsi kumamatira mwamphamvu kuzinthu zosiyanasiyana zapansi panthaka, kuphatikiza mapulasitiki, zoumba ndi zitsulo. Kuyika Posankha: Kuyika kwa mkuwa kopanda magetsi kumatha kuyika mkuwa pamalo enaake a gawo lapansi pogwiritsa ntchito njira zophimba nkhope. Mtengo Wotsika: Poyerekeza ndi njira zina, plating yamkuwa yopanda ma electroless ndi njira yotsika mtengo yoyika mkuwa pagawo laling'ono.

Kuipa kwa electroless copper plating Kuchepetsa kuyika:Poyerekeza ndi njira zopangira ma electroplating, plating yamkuwa yopanda ma elekitirodi nthawi zambiri imakhala ndi kutsika pang'onopang'ono, komwe kumatha kutalikitsa nthawi yonse yopangira ma electroplating. Makulidwe ochepa: Kuyika kwa mkuwa kopanda ma elekitirodi nthawi zambiri kumakhala koyenera kuyika zigawo zopyapyala zamkuwa motero sizoyenera kugwiritsa ntchito zomwe zimafuna kuchulukira. Kuvuta: Njirayi imafunikira kuwongolera mosamalitsa magawo osiyanasiyana, kuphatikiza kutentha, pH ndi kuchuluka kwa mankhwala, zomwe zimapangitsa kuti zikhale zovuta kuzikwaniritsa kuposa njira zina za electroplating. Kasamalidwe ka Zinyalala: Kutaya zinyalala plating solutions okhala ndi zitsulo zolemera zapoizoni kungayambitse mavuto a chilengedwe ndipo kumafuna kusamala mosamala.

Magawo ogwiritsira ntchito a electroless copper plating PCB Manufacturing:Electroless copper plating imagwiritsidwa ntchito kwambiri popanga matabwa osindikizira (PCBs) kuti apange ma conductive trace ndikukutidwa ndi mabowo. Makampani a Semiconductor: Amagwira ntchito yofunika kwambiri popanga zida za semiconductor monga zonyamulira chip ndi mafelemu otsogolera. Mafakitale oyendetsa magalimoto ndi ndege: Kuyika kwa mkuwa wopanda magetsi kumagwiritsidwa ntchito popanga zolumikizira zamagetsi, masiwichi ndi zida zamagetsi zogwira ntchito kwambiri. Zovala Zokongoletsera ndi Zogwira Ntchito: Kuyika kwa mkuwa kopanda magetsi kungagwiritsidwe ntchito popanga zokongoletsera pamagulu osiyanasiyana, komanso kuteteza dzimbiri komanso kuwongolera magetsi.

2.Copper plating pa PCB gawo lapansi

Kuyika kwa mkuwa pazigawo za PCB ndi gawo lofunikira pakupangira makina osindikizira (PCB). Copper imagwiritsidwa ntchito ngati chinthu chopangira electroplating chifukwa chamayendedwe ake abwino kwambiri amagetsi komanso kumamatira kwabwino kwa gawo lapansi. Njira yopangira mkuwa imaphatikizapo kuyika kansalu kakang'ono ka mkuwa pamwamba pa PCB kuti apange njira zoyendetsera magetsi.

Njira yopangira mkuwa pazigawo za PCB nthawi zambiri imakhala ndi izi: Kukonzekera Pamwamba:

Tsukani bwino gawo lapansi la PCB kuti muchotse zonyansa, ma oxides kapena zonyansa zilizonse zomwe zingalepheretse kumamatira ndikusokoneza mtundu wa plating.

Kukonzekera kwa Electrolyte:

Konzani njira ya electrolyte yokhala ndi mkuwa wa sulphate monga gwero la ayoni amkuwa. Electrolyte ilinso ndi zowonjezera zomwe zimayendetsa plating, monga ma leveling agents, zowunikira, ndi zosintha za pH.

Electrodeposition:

Lumikizani gawo lapansi lokonzekera la PCB mu njira ya electrolyte ndikuyika mwachindunji. PCB imagwira ntchito ngati cholumikizira cha cathode, pomwe anode yamkuwa imapezekanso mu yankho. Zomwe zikuchitika pano zimapangitsa kuti ayoni amkuwa mu electrolyte achepe ndikuyikidwa pa PCB pamwamba.

Kuwongolera magawo a plating:

Magawo osiyanasiyana amawongoleredwa mosamala panthawi yopaka, kuphatikiza kachulukidwe kakali pano, kutentha, pH, nthawi yoyambitsa ndi plating. Magawo awa amathandizira kuwonetsetsa kuyika kofanana, kumamatira, komanso makulidwe omwe amafunidwa amkuwa.

Chithandizo cha post-plating:

Mukafika makulidwe amkuwa omwe mukufuna, PCB imachotsedwa mumadzi osambira ndikuchapidwa kuti muchotse njira yotsalira ya electrolyte. Mankhwala owonjezera a pambuyo-plating, monga kuyeretsa pamwamba ndi passivation, akhoza kuchitidwa kuti apititse patsogolo ubwino ndi kukhazikika kwazitsulo zamkuwa.

Zinthu zomwe zimakhudza khalidwe la electroplating:

Kukonzekera Pamwamba:

Kuyeretsa bwino ndi kukonzekera pamwamba pa PCB ndikofunikira kuti muchotse zonyansa zilizonse kapena zigawo za oxide ndikuwonetsetsa kumamatira bwino kwa plating yamkuwa. Kuphatikizika kwa solution Plating:

Mapangidwe a yankho la electrolyte, kuphatikiza kuchuluka kwa mkuwa sulphate ndi zowonjezera, zimakhudza mtundu wa plating. The plating kusamba zikuchokera ayenera mosamala ankalamulira kukwaniritsa kufunika plating makhalidwe.

Zigawo za Plating:

Kuwongolera magawo oyikapo monga kachulukidwe kakali pano, kutentha, pH, kuyambitsa ndi kuyika nthawi ndikofunikira kuti zitsimikizire kuyika kofanana, kumamatira ndi makulidwe amkuwa.

Zamkatimu:

Mtundu ndi mtundu wa zinthu za gawo lapansi za PCB zidzakhudza kumamatira ndi mtundu wa plating zamkuwa. Zida zosiyanasiyana zapansi panthaka zingafunike kusintha kwa plating kuti mupeze zotsatira zabwino.

Pamwamba:

Kukula kwamphamvu kwa gawo lapansi la PCB kudzakhudza kumamatira ndi mtundu wa wosanjikiza wamkuwa. Kukonzekera bwino kwa pamwamba ndi kuyang'anira magawo a plating kumathandiza kuchepetsa mavuto okhudzana ndi kuuma

Ubwino wa PCB substrate copper plating:

Zabwino kwambiri zamagetsi conductivity:

Copper imadziwika chifukwa champhamvu kwambiri yamagetsi, ndikupangitsa kuti ikhale chisankho chabwino pazida zomangira za PCB. Izi zimatsimikizira kuyendetsa bwino komanso kodalirika kwa zizindikiro zamagetsi. Kumamatira kwabwino kwambiri:

Copper amawonetsa kumamatira kwabwino ku magawo osiyanasiyana, kuonetsetsa kuti pali mgwirizano wamphamvu komanso wokhalitsa pakati pa zokutira ndi gawo lapansi.

Kulimbana ndi Corrosion:

Copper imakhala ndi kukana bwino kwa dzimbiri, kuteteza zigawo za PCB zapansi ndikuwonetsetsa kudalirika kwa nthawi yayitali. Solderability: Kuyika kwa mkuwa kumapereka malo oyenerera kuti asungunuke, zomwe zimapangitsa kuti zikhale zosavuta kugwirizanitsa zipangizo zamagetsi panthawi ya msonkhano.

Kuwotcha kwamphamvu:

Copper ndi woyendetsa bwino kutentha, kupangitsa kuti ma PCB azitha kutentha bwino. Izi ndizofunikira makamaka pazogwiritsa ntchito mphamvu zambiri.

Zochepa ndi zovuta za copper electroplating:

Kuwongolera Makulidwe:

Kukwaniritsa kuwongolera bwino pa makulidwe amkuwa kumatha kukhala kovuta, makamaka m'malo ovuta kapena malo olimba pa PCB. Kufanana: Kuwonetsetsa kuti yunifolomu ya mkuwa imayikidwa pamwamba pa PCB, kuphatikizapo malo otsekedwa ndi zinthu zabwino, kungakhale kovuta.

Mtengo:

Electroplating copper ikhoza kukhala yokwera mtengo kwambiri poyerekeza ndi njira zina zopangira ma electroplating chifukwa cha mtengo wamankhwala opangira matanki, zida, ndi kukonza.

Kuwongolera Zinyalala:

Kutaya njira zopangira plating ndi kuthira madzi otayira okhala ndi ayoni amkuwa ndi mankhwala ena kumafunikira njira zoyendetsera zinyalala kuti muchepetse kuwonongeka kwa chilengedwe.

Kuvuta Kwambiri:

Electroplating copper imaphatikizapo magawo angapo omwe amafunikira kuwongolera mosamalitsa, komwe kumafunikira chidziwitso chapadera komanso makonzedwe ovuta a plating.

3.Kuyerekeza pakati pa electroless copper plating ndi electroplating

Kusiyanasiyana kwa machitidwe ndi khalidwe:

Pali kusiyana kwakukulu pamachitidwe ndi khalidwe pakati pa electroless copper plating ndi electroplating muzinthu izi:

Electroless copper plating ndi njira yoyika zinthu zomwe sizifuna gwero lamphamvu lakunja, pomwe electroplating imaphatikizapo kugwiritsa ntchito molunjika kuyika mkuwa wosanjikiza. Kusiyanasiyana kwa njira zoyikamo kungapangitse kusiyana kwa khalidwe la zokutira.

Electroless copper plating nthawi zambiri imapereka mawonekedwe ofananirako pamwamba pa gawo lonse lapansi, kuphatikiza madera okhazikika ndi mawonekedwe abwino. Izi zili choncho chifukwa plating imachitika mofanana pamalo onse mosasamala kanthu za momwe akuzungulira. Electroplating, kumbali ina, ikhoza kukhala ndi vuto lokwaniritsa yunifolomu m'malo ovuta kapena ovuta kufika.

Electroless copper plating imatha kufika pamlingo wokulirapo (chiyerekezo cha kutalika ndi m'lifupi) kuposa electroplating. Izi zimapangitsa kukhala oyenera ntchito amafuna mkulu mbali chiŵerengero katundu, monga kudzera-mabowo PCBs.

Electroless copper plating nthawi zambiri imapanga malo osalala, osalala kuposa electroplating.

Electroplating nthawi zina imatha kupangitsa kuti pakhale ma depositi osagwirizana, ankhanza kapena opanda kanthu chifukwa cha kusintha kwa kachulukidwe kakali pano komanso malo osambira. Ubwino wa mgwirizano pakati pa copper plating wosanjikiza ndi gawo lapansi ukhoza kusiyana pakati pa electroless copper plating ndi electroplating.

Electroless copper plating nthawi zambiri imapereka kumamatira kwabwinoko chifukwa cha makina omangira amkuwa opanda electroless ku gawo lapansi. Kuyika kumadalira kumakina ndi ma electrochemical, zomwe zimatha kupangitsa kuti zomangira zofooka nthawi zina.

Kuyerekeza Mtengo:

Chemical Deposition vs. Electroplating: Poyerekeza mtengo wa electroless copper plating ndi electroplating, zinthu zingapo ziyenera kuganiziridwa:

Mtengo wa mankhwala:

Electroless copper plating nthawi zambiri amafuna mankhwala okwera mtengo kwambiri poyerekeza ndi electroplating. Mankhwala omwe amagwiritsidwa ntchito popanga ma electroless plating, monga zochepetsera ndi zolimbitsa thupi, nthawi zambiri amakhala apadera komanso okwera mtengo.

Mtengo wa zida:

Magawo omangira amafunikira zida zovuta komanso zodula, kuphatikiza magetsi, zowongolera ndi anode. Makina opaka mkuwa opanda electroless ndi osavuta ndipo amafuna zigawo zochepa.

Ndalama zosamalira:

Zida zomangira zingafunikire kukonza nthawi ndi nthawi, kuwongolera, ndikusintha ma anode kapena zinthu zina. Ma electroless copper plating systems nthawi zambiri amafunikira kusamalidwa pafupipafupi ndipo amakhala ndi ndalama zochepa zokonza.

Kugwiritsa Ntchito Mankhwala Omatira:

Makina opangira ma plating amadya mankhwala opaka pamlingo wokwera kwambiri chifukwa chogwiritsa ntchito magetsi. Kugwiritsa ntchito mankhwala a electroless copper plating systems ndikotsika chifukwa electroplating reaction imachitika kudzera munjira yamankhwala.

Ndalama zoyendetsera zinyalala:

Electroplating imapanga zinyalala zina, kuphatikiza malo osambira omata ndi kutsuka madzi okhala ndi ayoni achitsulo, omwe amafunikira chithandizo choyenera ndikutaya. Izi zimawonjezera mtengo wonse wa plating. Electroless copper plating imatulutsa zinyalala zochepa chifukwa sizidalira ma ion zitsulo mosalekeza posamba.

Zovuta ndi Zovuta za Electroplating ndi Chemical Deposition:

Electroplating imafuna kuwongolera mosamalitsa magawo osiyanasiyana monga kachulukidwe wapano, kutentha, pH, nthawi yoyika ndikugwedeza. Kukwaniritsa mawonekedwe ofananirako komanso mawonekedwe omwe amafunidwa kumatha kukhala kovuta, makamaka muzojambula zovuta kapena madera otsika. Kukhathamiritsa kwa kapangidwe ka bafa la plating ndi magawo ake kungafune kuyesa kwakukulu komanso ukadaulo.

Electroless copper plating imafunanso kuwongolera magawo monga kuchepetsa ndende ya wothandizira, kutentha, pH ndi nthawi yopumira. Komabe, kuwongolera magawowa nthawi zambiri sikukhala kofunikira pakuyika kopanda ma electroless kuposa mu electroplating. Kukwaniritsa zomwe mukufuna plating, monga kuchuluka kwa plating, makulidwe, ndi kumamatira, kungafunebe kukhathamiritsa ndi kuwunika momwe ma plating amagwirira ntchito.

Pakupanga ma electroplating ndi electroless copper plating, kumamatira kuzinthu zosiyanasiyana zapansi panthaka kungakhale vuto wamba. Kukonzekera koyambirira kwa gawo lapansi kuti muchotse zowononga ndikulimbikitsa kumamatira ndikofunikira panjira zonse ziwiri.

Kuthetsa mavuto ndi kuthetsa mavuto mu electroplating kapena electroless copper plating kumafuna chidziwitso chapadera ndi chidziwitso. Nkhani monga kukhwimitsa, kusakhazikika bwino, kuphulika, kuphulika, kapena kusamata bwino kumatha kuchitika panjira zonse ziwiri, ndipo kuzindikira chomwe chimayambitsa ndi kukonza kungakhale kovuta.

Kuchuluka kwakugwiritsa ntchito ukadaulo uliwonse:

Electroplating imagwiritsidwa ntchito m'mafakitale osiyanasiyana kuphatikiza zamagetsi, zamagalimoto, zakuthambo ndi zodzikongoletsera zomwe zimafunikira kuwongolera kokwanira bwino, kumalizidwa kwapamwamba komanso mawonekedwe omwe amafunidwa. Amagwiritsidwa ntchito kwambiri pomaliza zokongoletsera, zokutira zitsulo, chitetezo cha kutu komanso kupanga zinthu zamagetsi.

Electroless copper plating imagwiritsidwa ntchito kwambiri pamakampani opanga zamagetsi, makamaka popanga ma board osindikizidwa (PCBs). Amagwiritsidwa ntchito popanga ma conductive njira, malo ogulitsidwa ndi kumaliza pamwamba pa PCB. Electroless copper plating imagwiritsidwanso ntchito kupangira zitsulo mapulasitiki, kupanga zolumikizira zamkuwa m'maphukusi a semiconductor, ndi ntchito zina zomwe zimafunikira yunifolomu ndi conformal mkuwa.

4.Copper mafunsidwe njira zosiyanasiyana PCB mitundu

PCB ya mbali imodzi:

Mu ma PCB a mbali imodzi, kuyika kwa mkuwa nthawi zambiri kumachitika pogwiritsa ntchito njira yochotsera. Gawo laling'ono nthawi zambiri limapangidwa ndi zinthu zopanda conductive monga FR-4 kapena phenolic resin, yokutidwa ndi mkuwa wochepa thupi kumbali imodzi. Chosanjikiza chamkuwa chimakhala ngati njira yoyendetsera dera. Njirayi imayamba ndikuyeretsa ndikukonzekera gawo lapansi kuti zitsimikizire kuti zimamatira bwino. Chotsatira ndikugwiritsa ntchito kagawo kakang'ono kakang'ono ka photoresist, kamene kamawonetsedwa ndi kuwala kwa UV kupyolera mu photomask kufotokozera dongosolo la dera. Malo owonekera a kukana amakhala osungunuka ndipo kenako amatsukidwa, kuwonetsa pansi pa mkuwa wosanjikiza. Madera a mkuwa oonekera amazikika pogwiritsa ntchito etchant monga ferric chloride kapena ammonium persulfate. The etchant kusankha amachotsa mkuwa wovumbuluka, kusiya mtundu wofunidwa wadera. Kukaniza kotsalako kumachotsedwa, ndikusiya zizindikiro zamkuwa. Pambuyo pa etching ndondomeko, ndi PCB akhoza kukumana njira zina zokonzekera pamwamba monga solder chigoba, chophimba kusindikiza, ndi ntchito zigawo zoteteza kuonetsetsa durability ndi chitetezo ku zinthu zachilengedwe.

PCB ya mbali ziwiri:

PCB yokhala ndi mbali ziwiri ili ndi zigawo zamkuwa kumbali zonse za gawo lapansi. Njira yoyika mkuwa mbali zonse ziwiri imaphatikizapo njira zowonjezera poyerekeza ndi ma PCB a mbali imodzi. Njirayi ndi yofanana ndi PCB yokhala ndi mbali imodzi, kuyambira ndikuyeretsa ndi kukonza gawo lapansi. Gawo la mkuwa limayikidwa mbali zonse za gawo lapansi pogwiritsa ntchito electroless copper plating kapena electroplating. Electroplating imagwiritsidwa ntchito pa sitepe iyi chifukwa imalola kuwongolera bwino makulidwe ndi mtundu wa mkuwa. Pambuyo poyika mkuwa, mbali zonse ziwiri zimakutidwa ndi photoresist ndipo mawonekedwe ozungulira amatanthauzidwa kudzera pakuwonekera ndi njira zachitukuko zofanana ndi za PCB za mbali imodzi. Madera amkuwa owonekera amamangika kuti apange mayendedwe ofunikira. Pambuyo pa etching, kukana kumachotsedwa ndipo PCB imadutsa njira zina zopangira monga solder mask application ndi chithandizo chapamwamba kuti amalize kupanga PCB yokhala ndi mbali ziwiri.

Multilayer PCB:

Ma PCB a Multilayer amapangidwa ndi zigawo zingapo zamkuwa ndi zotchingira zomangika pamwamba pa mnzake. Kuyika kwa mkuwa mu ma PCB ambiri kumaphatikizapo njira zingapo zopangira njira zoyendetsera pakati pa zigawo. Njirayi imayamba ndikupanga zigawo za PCB, zofanana ndi ma PCB a mbali imodzi kapena mbali ziwiri. Chigawo chilichonse chimakonzedwa ndipo chojambula chojambula chimagwiritsidwa ntchito kutanthauzira dera, ndikutsatiridwa ndi kuyika kwa mkuwa kudzera pa electroplating kapena electroless copper plating. Pambuyo poyika, gawo lililonse limakutidwa ndi zotchingira (nthawi zambiri epoxy-based prepreg kapena utomoni) ndikumangirira pamodzi. Zigawozo zimagwirizanitsidwa pogwiritsa ntchito kubowola molondola komanso njira zolembera zamakina kuti zitsimikizire kulumikizana kolondola pakati pa zigawo. Pamene zigawo zimagwirizana, vias amapangidwa ndi pobowola mabowo mwa zigawo pa mfundo zenizeni kumene interconnects chofunika. The vias ndiye yokutidwa ndi mkuwa ntchito electroplating kapena electroless mkuwa plating kulenga kugwirizana magetsi pakati pa zigawo. Njirayi imapitilira ndikubwereza masitepe osanjikiza, kubowola, ndi zokutira zamkuwa mpaka magawo onse ofunikira ndi zolumikizira zidapangidwa. Gawo lomaliza limaphatikizapo chithandizo chapamwamba, kugwiritsa ntchito chigoba cha solder ndi njira zina zomaliza kuti amalize kupanga PCB yamitundu yambiri.

High Density Interconnect (HDI) PCB:

HDI PCB ndi PCB yamitundu yambiri yopangidwa kuti igwirizane ndi zozungulira zazikulu komanso mawonekedwe ang'onoang'ono. Kuyika kwa mkuwa mu ma PCB a HDI kumaphatikizapo njira zapamwamba zothandizira mawonekedwe abwino ndi mapangidwe olimba. Njirayi imayamba ndikupanga zigawo zingapo zowonda kwambiri, zomwe nthawi zambiri zimatchedwa core material. Miyendo iyi imakhala ndi zojambulazo zopyapyala zamkuwa kumbali zonse ndipo zimapangidwa kuchokera kuzinthu zopangira utomoni wapamwamba kwambiri monga BT (Bismaleimide Triazine) kapena PTFE (Polytetrafluoroethylene). Zida zazikuluzikulu zimayikidwa ndi laminated pamodzi kuti apange mawonekedwe amitundu yambiri. Kubowola kwa laser kumagwiritsidwa ntchito popanga ma microvias, omwe ndi mabowo ang'onoang'ono omwe amalumikiza zigawozo. Ma Microvias nthawi zambiri amadzazidwa ndi zinthu zopangira zinthu monga mkuwa kapena conductive epoxy. Pambuyo popanga ma microvias, zigawo zowonjezera zimayikidwa ndi laminated. The sequential lamination ndi laser kubowola ndondomeko kubwerezedwa kulenga angapo zosanjikizana zigawo ndi microvia interconnects. Pomaliza, mkuwa umayikidwa pamwamba pa HDI PCB pogwiritsa ntchito njira monga electroplating kapena electroless copper plating. Popeza mawonekedwe abwino komanso kachulukidwe kachulukidwe ka ma PCB a HDI, kuyika kumayendetsedwa mosamala kuti mukwaniritse makulidwe ndi mtundu wa mkuwa wofunikira. Njirayi imathera ndi mankhwala owonjezera pamwamba ndi njira zomaliza kuti amalize kupanga HDI PCB, yomwe ingaphatikizepo kugwiritsa ntchito chigoba cha solder, kumaliza ntchito ndi kuyesa.

Flexible circuit board:

Ma PCB osinthika, omwe amadziwikanso kuti ma flex circuits, adapangidwa kuti azikhala osinthika komanso otha kusintha mawonekedwe kapena mapindika osiyanasiyana panthawi yogwira ntchito. Kuyika kwa mkuwa mu ma PCB osinthika kumaphatikizapo njira zina zomwe zimakwaniritsa kusinthasintha komanso kukhazikika. Ma PCB osinthika amatha kukhala ambali imodzi, mbali ziwiri, kapena zosanjikiza zambiri, ndipo njira zoyikamo zamkuwa zimasiyana malinga ndi kapangidwe kake. Nthawi zambiri, ma PCB osinthika amagwiritsa ntchito zojambulazo zocheperako poyerekeza ndi ma PCB olimba kuti azitha kusinthasintha. Kwa ma PCB osinthika a mbali imodzi, ndondomekoyi ndi yofanana ndi ma PCB olimba a mbali imodzi, ndiko kuti, chingwe chochepa cha mkuwa chimayikidwa pazitsulo zosinthika pogwiritsa ntchito electroless copper plating, electroplating, kapena kuphatikiza zonse ziwiri. Kwa ma PCB okhala ndi mbali ziwiri kapena angapo osanjikiza, njirayi imaphatikizapo kuyika mkuwa kumbali zonse ziwiri za gawo lapansi losinthika pogwiritsa ntchito electroless copper plating kapena electroplating. Poganizira zapadera zamakina azinthu zosinthika, kuyika kumayendetsedwa mosamala kuti kuwonetsetse kuti kumamatira komanso kusinthasintha. Pambuyo poyika mkuwa, PCB yosinthika imadutsa njira zowonjezera monga kubowola, kuwongolera dera, ndi njira zochizira pamwamba kuti apange mayendedwe ofunikira ndikumaliza kupanga PCB yosinthika.

5.Zotsogola ndi Zatsopano mu Copper Deposition pa PCBs

Zotukuka Zamakono Zamakono: Kwa zaka zambiri, ukadaulo woyika mkuwa pa PCB wapitilira kusinthika ndikusintha, zomwe zidapangitsa kuti magwiridwe antchito achuluke komanso kudalirika. Zina mwazinthu zaposachedwa kwambiri zaukadaulo pakuyika kwa mkuwa kwa PCB zikuphatikiza:

Advanced plating Technology:

Ukadaulo watsopano wopukutira, monga pulse plating ndi reverse pulse plating, apangidwa kuti akwaniritse kuyika kwa mkuwa kofananako. Matekinolojewa amathandizira kuthana ndi zovuta monga kukhwimitsa pamwamba, kukula kwambewu ndi kugawa makulidwe kuti magetsi azigwira bwino ntchito.

Direct zitsulo:

Kupanga kwachikhalidwe kwa PCB kumaphatikizapo njira zingapo zopangira njira zoyendetsera, kuphatikiza kuyika mbeu musanayike mkuwa. Kukula kwa njira zopangira zitsulo kumachepetsa kufunikira kwa gawo losiyana la mbewu, potero kumathandizira kupanga, kuchepetsa ndalama komanso kudalirika.

Ukadaulo wa Microvia:

Microvias ndi mabowo ang'onoang'ono omwe amalumikiza magawo osiyanasiyana mu PCB yamitundu yambiri. Kupita patsogolo kwaukadaulo wa microvia monga kubowola kwa laser ndi plasma etching kumathandizira kupanga ma microvias ang'onoang'ono, olondola kwambiri, kupangitsa mabwalo okwera kwambiri komanso kukhulupirika kwa ma siginecha. Surface Finish Innovation: Kutsirizitsa kwapamwamba ndikofunikira kuti muteteze mikwingwirima yamkuwa kuchokera ku okosijeni ndikupereka solderability. Kutukuka kwaukadaulo wamankhwala apamwamba, monga Immersion Silver (ImAg), Organic Solderability Preservative (OSP), ndi Electroless Nickel Immersion Gold (ENIG), zimapereka chitetezo chambiri cha dzimbiri, kumapangitsa kugulitsa, ndikuwonjezera kudalirika konse.

Nanotechnology ndi Copper Deposition: Nanotechnology imagwira ntchito yofunika kwambiri pakupititsa patsogolo kuyika kwa mkuwa kwa PCB. Ntchito zina za nanotechnology pakuyika mkuwa ndi izi:

Nanoparticle-based plating:

Mkuwa nanoparticles akhoza kuphatikizidwa mu plating njira kumapangitsanso mafunsidwe ndondomeko. Ma nanoparticles awa amathandizira kukonza kumatira kwa mkuwa, kukula kwambewu ndi kugawa, potero amachepetsa kukana komanso kupititsa patsogolo ntchito zamagetsi.

Nanostructured Conductive Materials:

Nanostructured zipangizo, monga carbon nanotubes ndi graphene, akhoza Integrated mu magawo PCB kapena kukhala conductive fillers pa deposition. Zinthuzi zili ndi mphamvu zamagetsi zamagetsi, mphamvu zamakina ndi zinthu zotentha, potero kuwongolera magwiridwe antchito onse a PCB.

Nanocoating:

Nanocoating angagwiritsidwe ntchito pamwamba PCB kusintha kusalala pamwamba, solderability ndi dzimbiri chitetezo. Zovala izi nthawi zambiri zimapangidwa kuchokera ku nanocomposites zomwe zimapereka chitetezo chabwino kuzinthu zachilengedwe ndikuwonjezera moyo wa PCB.

Nanoscale interconnects:Ma nanoscale interconnects, monga nanowires ndi nanorods, akufufuzidwa kuti athe kuyatsa mabwalo apamwamba mu PCBs. Zomangamangazi zimathandizira kuphatikizika kwa mabwalo ambiri kudera laling'ono, zomwe zimapangitsa kuti pakhale zida zazing'ono, zamagetsi zamagetsi.

Zovuta ndi mayendedwe amtsogolo: Ngakhale kupita patsogolo kwakukulu, zovuta zingapo ndi mwayi udakali wopititsa patsogolo kuyika kwa mkuwa pa PCB. Zovuta zina zazikulu ndi mayendedwe amtsogolo ndi awa:

Kudzaza Kwa Copper mu High Aspect Ratio Structures:

Mawonekedwe apamwamba kwambiri monga vias kapena ma microvias amapereka zovuta kuti akwaniritse kudzaza kwa mkuwa kofanana komanso kodalirika. Kafukufuku wowonjezereka akufunika kuti apange njira zapamwamba zopangira plating kapena njira zina zodzaza kuti athe kuthana ndi zovutazi ndikuwonetsetsa kuti mkuwa uyenera kuyikidwa m'magawo apamwamba kwambiri.

Kuchepetsa Copper Trace Width:

Pamene zipangizo zamagetsi zimakhala zing'onozing'ono komanso zowonjezereka, kufunikira kwa njira zochepetsera zamkuwa kumapitirira kukula. Chovuta ndikukwaniritsa kuyika kwa mkuwa kofanana ndi kodalirika mkati mwa njira zopapatizazi, kuwonetsetsa kuti magetsi akugwira ntchito komanso kudalirika.

Njira zina za conductor:

Ngakhale kuti mkuwa ndi chinthu chomwe chimagwiritsidwa ntchito kwambiri, zida zina monga siliva, aluminiyamu, ndi carbon nanotubes zikufufuzidwa chifukwa cha mawonekedwe awo apadera komanso ubwino wake. Kafukufuku wamtsogolo atha kuyang'ana kwambiri pakupanga njira zopangira zida zopangira izi kuti zithetse zovuta monga kumamatira, kukana, komanso kuyanjana ndi njira zopangira PCB. ZachilengedweNjira Zaubwenzi:

Makampani a PCB akugwira ntchito mosalekeza kutsata njira zachilengedwe. Zomwe zikuchitika m'tsogolomu zitha kuyang'ana kwambiri kuchepetsa kapena kuthetsa kugwiritsa ntchito mankhwala owopsa pakuyika mkuwa, kukhathamiritsa kugwiritsa ntchito mphamvu, komanso kuchepetsa kuwononga zinyalala kuti muchepetse kuwonongeka kwa chilengedwe pakupanga PCB.

Kuyerekeza Kwapamwamba ndi Kujambula:

Njira zofananira ndi zofananira zimathandizira kukhathamiritsa njira zoyikapo mkuwa, kulosera momwe zimakhalira, ndikuwongolera kulondola komanso kuchita bwino pakupanga kwa PCB. Kupita patsogolo kwamtsogolo kungaphatikizepo kuphatikizira zida zofananira ndi zida zofananira pamapangidwe ndi kupanga kuti athe kuwongolera bwino komanso kukhathamiritsa.

6.Quality Assurance and Control of Copper Deposition for PCB Substrates

Kufunika kotsimikizira zaubwino: Kutsimikizika kwaubwino ndikofunikira kwambiri pakuyika mkuwa pazifukwa izi:

Kudalirika kwazinthu:

Kuyika kwa mkuwa pa PCB kumapanga maziko olumikizira magetsi. Kuwonetsetsa kuti kusungidwa kwa mkuwa n'kofunika kwambiri pa ntchito yodalirika komanso yokhalitsa ya zipangizo zamagetsi. Kuyika kwa mkuwa kosauka kumatha kubweretsa zolakwika zolumikizana, kutsika kwa ma siginecha, komanso kudalirika kwathunthu kwa PCB.

Magetsi:

Ubwino wa plating zamkuwa umakhudza mwachindunji magwiridwe antchito a PCB. Makulidwe amtundu umodzi wamkuwa ndi kugawa, kumaliza kosalala pamwamba, ndi kumamatira koyenera ndikofunikira kuti mukwaniritse kukana kochepa, kufalitsa ma siginecha koyenera, komanso kutayika kwazizindikiro kochepa.

Chepetsani ndalama:

Chitsimikizo chaubwino chimathandiza kuzindikira ndi kupewa mavuto atangoyamba kumene, kuchepetsa kufunika kokonzanso kapena kuchotsa ma PCB olakwika. Izi zitha kupulumutsa ndalama ndikuwongolera magwiridwe antchito onse.

Kukwaniritsa Makasitomala:

Kupereka zinthu zamtengo wapatali ndizofunikira kwambiri kuti makasitomala athe kukhutira komanso kupanga mbiri yabwino pamsika. Makasitomala amayembekeza zinthu zodalirika komanso zolimba, ndipo kutsimikizika kwamtundu kumawonetsetsa kuti kuyika kwa mkuwa kumakwaniritsa kapena kupitilira zomwe amayembekeza.

Njira zoyesera ndi zowunikira pakuyika kwa mkuwa: Njira zosiyanasiyana zoyesera ndi zowunikira zimagwiritsidwa ntchito kuti zitsimikizire mtundu wa kuyika kwa mkuwa pa PCB. Njira zina zodziwika bwino ndi izi:

Kuyang'anira Zowoneka:

Kuyang'ana kowoneka ndi njira yofunikira komanso yofunikira yodziwira zolakwika zowoneka bwino zapamtunda monga zokanda, zopindika kapena zolimba. Kuyang'ana kumeneku kutha kuchitidwa pamanja kapena mothandizidwa ndi makina opangira mawonekedwe (AOI).

Maikrosikopu:

Ma Microscopy pogwiritsa ntchito njira monga kusanthula ma electron microscopy (SEM) atha kupereka kusanthula kwatsatanetsatane pakuyika kwa mkuwa. Ikhoza kuyang'anitsitsa kumapeto kwa pamwamba, kumamatira ndi kufanana kwa mkuwa wamkuwa.

Kusanthula kwa X-ray:

Njira zowunikira ma X-ray, monga X-ray fluorescence (XRF) ndi X-ray diffraction (XRD), zimagwiritsidwa ntchito kuyeza kapangidwe kake, makulidwe ndi kugawa kwa ma depositi amkuwa. Njirazi zimatha kuzindikira zonyansa, kapangidwe kazinthu, ndikuzindikira kusagwirizana kulikonse pakuyika kwa mkuwa.

Kuyeza Magetsi:

Chitani njira zoyesera zamagetsi, kuphatikiza kuyeza kukana ndi kuyesa kopitilira, kuti muwunikire magwiridwe antchito amagetsi a ma depositi amkuwa. Mayeserowa amathandiza kuonetsetsa kuti mkuwa wosanjikiza uli ndi madulidwe ofunikira komanso kuti mulibe zotsegula kapena zazifupi mkati mwa PCB.

Mayeso a Peel Strength:

Kuyesa kwamphamvu kwa peel kumayesa mphamvu yolumikizana pakati pa wosanjikiza wamkuwa ndi gawo lapansi la PCB. Zimatsimikizira ngati gawo la mkuwa lili ndi mphamvu zokwanira zogwirira ntchito komanso njira zopangira PCB.

Miyezo ndi malamulo amakampani: Makampani a PCB amatsata miyezo ndi malamulo osiyanasiyana amakampani kuti awonetsetse kuti mkuwa umakhala wabwino. Miyezo ndi malamulo ofunikira ndi awa:

IPC-4552:

Muyezowu umatchula zofunikira pazamankhwala opanda nickel/immersion gold (ENIG) omwe amagwiritsidwa ntchito kwambiri pa PCB. Imatanthawuza makulidwe ochepera a golide, makulidwe a faifi tambala ndi mtundu wapamtunda wamankhwala odalirika komanso olimba a ENIG.

IPC-A-600:

Muyezo wa IPC-A-600 umapereka malangizo ovomerezeka a PCB, kuphatikiza milingo yamagulu a copper plating, zolakwika zapamtunda ndi miyezo ina yabwino. Imagwiritsidwa ntchito ngati chiwongolero chowunikira komanso kuvomereza kuyika kwa mkuwa pa PCBs. Malangizo a RoHS:

Lamulo la Restriction of Hazardous Substances (RoHS) limaletsa kugwiritsa ntchito zinthu zina zowopsa pazinthu zamagetsi, kuphatikiza lead, mercury ndi cadmium. Kutsatira malangizo a RoHS kumawonetsetsa kuti ma PCB a mkuwa alibe zinthu zovulaza, kuwapangitsa kukhala otetezeka komanso otetezeka ku chilengedwe.

ISO 9001:

ISO 9001 ndi muyezo wapadziko lonse lapansi wamakina oyang'anira zabwino. Kukhazikitsa ndikugwiritsa ntchito ISO 9001-based quality management system kumawonetsetsa kuti njira zoyenera ndi zowongolera zili m'malo kuti nthawi zonse azipereka zinthu zomwe zikugwirizana ndi zomwe makasitomala amafuna, kuphatikiza mtundu wa copper deposition pa PCB.

Kuchepetsa zovuta zomwe zimachitika nthawi zambiri komanso zolakwika: Mavuto ena omwe amapezeka nthawi zambiri mkuwa ndi awa:

Kusamamatira kokwanira:

Kusamanga bwino kwa mkuwa wosanjikiza ku gawo lapansi kungayambitse delamination kapena peeling. Kuyeretsa bwino pamwamba, kuwotcha makina, ndi njira zothandizira kumata zingathandize kuthetsa vutoli.

Makulidwe a Copper Osafanana:

Makulidwe a mkuwa osagwirizana angayambitse kusagwirizana komanso kulepheretsa kufalikira kwa siginecha. Kukongoletsedwa ndi ma plating parameters, kugwiritsa ntchito kugunda kwa mtima kapena kusinthasintha kwa pulse ndikuwonetsetsa kugwedezeka koyenera kungathandize kukwaniritsa makulidwe a mkuwa wofanana.

Voids ndi Pinholes:

Ma voids ndi ma pinholes mumkuwa amatha kuwononga kulumikizana kwamagetsi ndikuwonjezera chiopsezo cha dzimbiri. Kuwongolera koyenera kwa plating magawo ndi kugwiritsa ntchito zowonjezera zowonjezera kungachepetse kupezeka kwa voids ndi ma pinholes.

Pamwamba:

Kuvuta kopitilira muyeso kumatha kusokoneza magwiridwe antchito a PCB, kusokoneza kugulitsa ndi kukhulupirika kwamagetsi. Kuwongolera koyenera kwa magawo oyika mkuwa, chithandizo chamankhwala chisanachitike komanso njira zochiritsira zimathandizira kuti pakhale kutha kwapamwamba.

Kuti muchepetse zovuta izi ndi zofookazi, njira zoyenera zowongolera ziyenera kukhazikitsidwa, kuwunika pafupipafupi ndi kuyesa kuyenera kuchitidwa, ndipo miyezo ndi malamulo amakampani ayenera kutsatiridwa. Izi zimatsimikizira kusasinthika, kodalirika komanso kukhazikitsidwa kwapamwamba kwa mkuwa pa PCB. Kuonjezera apo, kupititsa patsogolo ndondomeko zomwe zikuchitika, maphunziro a ogwira ntchito, ndi njira zoperekera ndemanga zimathandizira kuzindikira madera omwe angasinthidwe ndikuthana ndi mavuto omwe angakhale ovuta kwambiri.

Kuyika kwa mkuwa pa gawo lapansi la PCB ndi gawo lofunikira kwambiri pakupanga kwa PCB. Electroless copper deposition and electroplating ndi njira zazikulu zomwe zimagwiritsidwa ntchito, iliyonse ili ndi ubwino wake ndi zolephera. Kupita patsogolo kwaukadaulo kukupitilizabe kuyambitsa zatsopano pakuyika kwa mkuwa, motero kuwongolera magwiridwe antchito a PCB ndi kudalirika.Chitsimikizo chaubwino ndi kuwongolera zimagwira ntchito yofunika kwambiri pakuwonetsetsa kuti ma PCB apamwamba kwambiri apangidwa. Pomwe kufunikira kwa zida zazing'ono, zothamanga, komanso zodalirika zamagetsi zikuchulukirachulukira, kufunikira kolondola komanso kuchita bwino paukadaulo woyika mkuwa pagawo la PCB. Zindikirani: Kuwerengera kwa mawu m'nkhaniyi ndi pafupifupi mawu 3,500, koma chonde dziwani kuti kuwerengera kwenikweni kwa mawu kumatha kusiyana pang'ono panthawi yokonza ndikuwongolera.

Nthawi yotumiza: Sep-13-2023

Kubwerera