Pomwe kufunikira kwa mayankho osinthika komanso ophatikizika amagetsi kukupitilirabe, ma PCB okhazikika asanduka chisankho chodziwika bwino pakupanga ndi kupanga kwa PCB. Ma board awa amaphatikiza maubwino a PCB okhazikika komanso osinthika kuti azitha kusinthasintha popanda kusiya kukhazikika komanso magwiridwe antchito. Kuti mupange ma PCB odalirika komanso okhazikika, kumvetsetsa bwino masanjidwe a stack-up ndikofunikira. Mapangidwe a stack-up amatsimikizira makonzedwe ndi mawonekedwe a PCB, zomwe zimakhudza mwachindunji machitidwe ake ndi kupanga kwake.Kalozera watsatanetsataneyu adzafufuza zovuta za ma PCB osasunthika okhazikika, ndikupereka zidziwitso zofunikira kuti athandizire opanga kupanga zisankho zodziwikiratu panthawi yopanga. Idzakhudza magawo osiyanasiyana kuphatikiza kusankha kwazinthu, kuyika masanjidwe, malingaliro a kukhulupirika kwa ma sign, kuwongolera kwa impedance, ndi zovuta zopanga. Pomvetsetsa zovuta za ma stackups okhazikika a PCB, opanga amatha kutsimikizira kukhulupirika ndi kudalirika kwa mapangidwe awo. Adzakulitsa kukhulupirika kwa ma sign, kuchepetsa kusokoneza kwa ma elekitiroma (EMI) ndikuwongolera njira zopangira bwino. Kaya ndinu watsopano ku mapangidwe okhwima a PCB kapena mukuyang'ana kuti muwonjezere chidziwitso chanu, bukhuli lidzakhala gwero lamtengo wapatali, kukuthandizani kuti muzitha kuyang'ana zovuta za masinthidwe a stacking ndikupanga mayankho apamwamba, okhwima a PCB azinthu zosiyanasiyana.

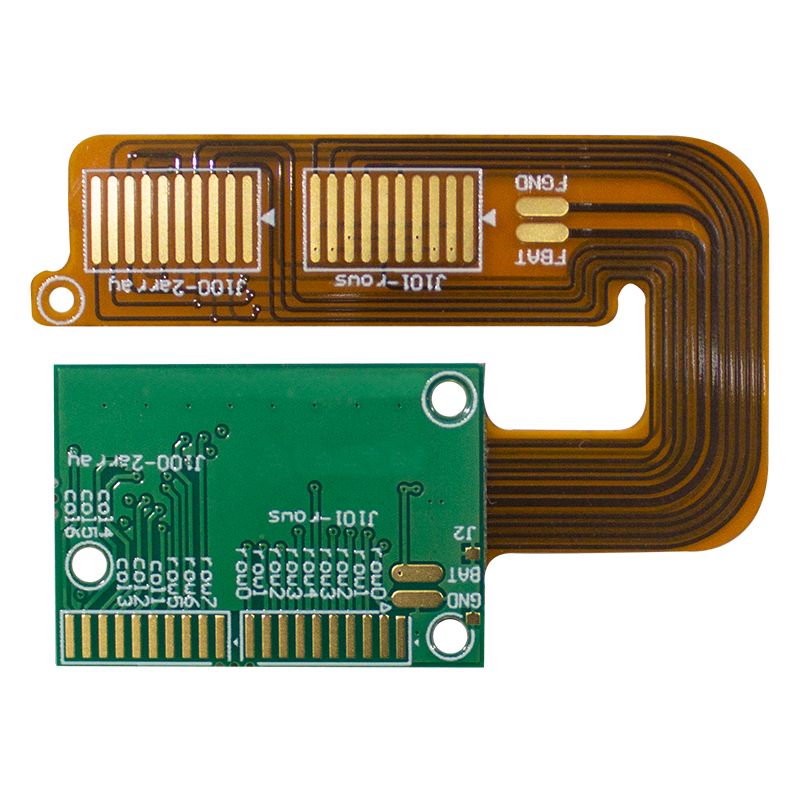

1.Kodi bolodi lolimba-flex ndi chiyani?

Rigid-flex board, yomwe imadziwikanso kuti rigid-flex printed circuit board (PCB), ndi PCB yomwe imaphatikiza magawo okhwima komanso osinthika pa bolodi limodzi.Zimaphatikiza ubwino wa ma PCB okhwima komanso osinthika kuti apititse patsogolo kusinthasintha komanso kukhazikika. Mu bolodi lokhazikika, gawo lolimbalo limapangidwa ndi zinthu zachikhalidwe za PCB (monga FR4), pomwe gawo losinthika limapangidwa ndi zinthu zosinthika za PCB (monga polyimide). Zigawozi zimalumikizidwa kudzera m'mabowo kapena zolumikizira zopindika kuti apange bolodi limodzi lophatikizika. Magawo okhwima amapereka chithandizo ndi kukhazikika kwa zigawo, zolumikizira, ndi zinthu zina zamakina, zofanana ndi PCB yokhazikika yokhazikika. Mbali yosinthika, kumbali ina, imalola bolodi lozungulira kuti lipirire ndi kupindika, kulola kuti ligwirizane ndi zipangizo zamagetsi zokhala ndi malo ochepa kapena mawonekedwe osagwirizana. Ma board olimba osinthika amapereka maubwino angapo kuposa ma PCB okhazikika kapena osinthika. Amachepetsa kufunikira kwa zolumikizira ndi zingwe, kupulumutsa malo, kuchepetsa nthawi ya msonkhano, ndikuwonjezera kudalirika pochotsa zomwe zingalephereke. Kuphatikiza apo, matabwa olimba amathandizira kamangidwe kake pothandizira kulumikizana pakati pa zolimba ndi zopindika, kuchepetsa zovuta zamayendedwe ndikuwongolera kukhulupirika kwa ma siginecha. Ma board a Rigid-flex nthawi zambiri amagwiritsidwa ntchito pomwe malo ali ochepa kapena bolodi imayenera kugwirizana ndi mawonekedwe kapena mbiri inayake. Nthawi zambiri amapezeka muzamlengalenga, zida zamankhwala, zamagetsi zamagalimoto ndi zida zamagetsi zomwe kukula, kulemera ndi kudalirika ndizofunikira. Kupanga ndi kupanga matabwa olimba osinthika kumafuna chidziwitso chapadera ndi ukadaulo chifukwa chophatikiza zinthu zolimba komanso zosinthika komanso zolumikizirana. Chifukwa chake, ndikofunikira kugwira ntchito ndi wopanga PCB wodziwa bwino yemwe amatha kuthana ndi zovuta zopanga ma board okhazikika.

2.N'chifukwa chiyani okhwima flex pcb stacking kasinthidwe zofunika?

Mechanical Integrity:

Ma PCB olimba-flex adapangidwa kuti azipereka kusinthasintha komanso kudalirika. Kukonzekera kwa stacking kumatsimikizira makonzedwe a zigawo zolimba komanso zosinthika, kuonetsetsa kuti bolodi ikhoza kupirira kupindika, kupindika ndi zovuta zina zamakina popanda kusokoneza kukhulupirika kwake. Kuyanjanitsa koyenera ndikofunikira kuti mupewe kutopa kwa PCB, kupsinjika, komanso kulephera pakapita nthawi.

Kukonza malo:

Ma board a Rigid-flex amagwiritsidwa ntchito kwambiri pazida zamagetsi zamagetsi zokhala ndi malo ochepa. Masanjidwe osanjikizidwa amalola opanga kugwiritsa ntchito bwino malo omwe alipo pokonza zigawo ndi zigawo zake m'njira yomwe imakulitsa kugwiritsa ntchito malo a 3D. Izi zimathandiza kuti ma PCB ayikidwe m'mipanda yolimba, zida zazing'ono komanso zovuta zamitundu. Signal Integrity:

Kukhulupirika kwa chizindikiro cha PCB yolimba yolimba ndikofunikira kuti igwire bwino ntchito. Kusintha kwa stacking kumachita gawo lofunikira pakukhathamiritsa kukhulupirika kwa ma siginecha poganizira zinthu monga kuletsa kuwongolera, kuwongolera mizere yopatsira, ndikuchepetsa crosstalk. Kusanjikiza koyenera kumatha kuwonetsetsa kuti ma siginecha azithamanga kwambiri, achepetse kutsika kwa ma sign, ndikuwonetsetsa kutumizidwa kwa data molondola.

Kasamalidwe ka Kutentha:

Zipangizo zamagetsi zimapanga kutentha, ndipo kasamalidwe koyenera ka kutentha ndi kofunikira kuti tipewe kutenthedwa ndi kuwonongeka kwa zigawo zikuluzikulu. Kusanjikiza kokhazikika kwa ma PCB okhazikika-osinthika amalola kuyika mwanzeru ma vias otentha, zigawo zamkuwa, ndi masinki otentha kuti azitha kutentha bwino. Poganizira nkhani zamafuta panthawi yopangira zopangira zinthu zambiri, opanga amatha kuwonetsetsa kuti PCB imakhala ndi moyo wautali komanso wodalirika.

Malingaliro Opanga:

Kusintha kwa stacking kumakhudza njira yopangira PCB yokhazikika. Zimatsimikizira dongosolo lomwe zigawozo zimagwirizanitsidwa palimodzi, kugwirizanitsa ndi kulembetsa zigawo zosinthika ndi zolimba, ndi kuyika kwa zigawo. Posankha mosamalitsa masanjidwe a stack-up, okonza amatha kukonza njira zopangira, kuchepetsa ndalama zopangira, komanso kuchepetsa chiopsezo cha zolakwika zopanga.

3.Key zigawo za rigid-flex PCB stackup

Mukapanga chosungira chokhazikika cha PCB, pali zinthu zingapo zofunika kuziganizira. Zigawozi zimagwira ntchito yofunika kwambiri popereka chithandizo chofunikira, kulumikizana kwamagetsi, komanso kusinthasintha pamapangidwe onse a PCB. Zotsatirazi ndi zigawo zazikulu za PCB yokhazikika yokhazikika:

Wokhazikika wosanjikiza:

Chosanjikiza chokhazikika nthawi zambiri chimapangidwa kuchokera ku zinthu zolimba monga FR-4 kapena zinthu zofananira. wosanjikiza ichi amapereka mphamvu makina ndi bata kwa PCB. Imakhalanso ndi zigawo ndipo imalola kuyika zida zapamtunda (SMD) ndi zida zapabowo. Chosanjikiza chokhazikika chimapereka maziko olimba a wosanjikiza wosinthika ndikuwonetsetsa kulumikizana koyenera komanso kukhazikika kwa PCB yonse.

Flexible layer:

Chigawo chosinthika chimakhala ndi zinthu zosinthika monga polyimide kapena zinthu zofananira. Chigawochi chimalola PCB kupindika, kupindika, ndi kupindika. The flex layer ndipamene pali zolumikizira zambiri zozungulira ndi magetsi. Zimapereka kusinthasintha koyenera kwa mapulogalamu omwe amafuna kuti PCB ipindike kapena igwirizane ndi mawonekedwe kapena malo osiyanasiyana. Kusinthasintha kwa gawoli kuyenera kuganiziridwa mosamala kuti zitsimikizire kuti zikugwirizana ndi zofunikira za ntchitoyo.

Zomatira:

Zomatira ndi zomata zopyapyala zomwe zimagwiritsidwa ntchito pakati pa wosanjikiza wokhazikika ndi wosanjikiza wosinthika. Cholinga chake chachikulu ndikumangirira zigawo zolimba komanso zosinthika palimodzi, kupereka kukhulupirika kwadongosolo kwa laminate. Zimatsimikizira kuti zigawozo zimakhalabe zogwirizana kwambiri wina ndi mzake ngakhale panthawi yopindika kapena kuyendayenda. Zomatira zomatira zimagwiranso ntchito ngati zida za dielectric, zomwe zimapereka kutsekemera pakati pa zigawo. Kusankhidwa kwa zomatira ndikofunikira chifukwa kumafunika kukhala ndi zida zabwino zomangira, kulimba kwa dielectric, komanso kugwirizana ndi zinthu zoyambira.

Kuwonjezera ndi Kuphimba:

Zowonjezera ndi zophimba ndi zigawo zowonjezera zomwe nthawi zambiri zimawonjezeredwa ku PCB stackup kuti iwonjezere mphamvu zamakina, chitetezo, ndi kudalirika. Zowonjezera zingaphatikizepo zipangizo monga FR-4 kapena mapepala opanda zomatira a polyimide omwe amapangidwa ndi laminated kumadera ena a zigawo zolimba kapena zosinthika kuti apereke zowonjezereka ndi chithandizo. Malo a PCB amakutidwa ndi zokutira monga masks a solder ndi zokutira zoteteza kuti zitetezedwe kuzinthu zachilengedwe monga chinyezi, fumbi, komanso kupsinjika kwamakina.

Zigawo zazikuluzikuluzi zimagwirira ntchito limodzi kuti zipange mosasunthika wosasunthika wa PCB womwe umakwaniritsa zofunikira za pulogalamuyo. Kukhazikika kwamapangidwe ndi kusinthasintha komwe kumaperekedwa ndi zigawo zolimba komanso zosinthika, komanso zigawo zomata, zimatsimikizira kuti PCB imatha kupirira kupindika kapena kusuntha popanda kusokoneza kukhulupirika kwa dera. Kuphatikiza apo, kugwiritsa ntchito zolimbitsa thupi ndi zofunda kumawonjezera kudalirika komanso chitetezo chonse cha PCB. Posankha mosamala komanso kupanga zidazi, mainjiniya amatha kupanga ma PCB olimba komanso odalirika.

4.Rigid-flex PCB stackup mtundu wa kasinthidwe

Popanga ma stackups okhazikika a PCB, mitundu yosiyanasiyana ya kasinthidwe ingagwiritsidwe ntchito kutengera zofunikira za pulogalamuyo. Kukonzekera kwa stack-up kumatsimikizira kuchuluka kwa zigawo zomwe zikuphatikizidwa muzojambula ndi dongosolo la zigawo zolimba ndi zosinthika. Zotsatirazi ndi mitundu itatu yodziwika bwino yosasinthika ya PCB:

1 wosanjikiza wokhazikika komanso wofewa lamination:

Mu kasinthidwe, PCB imakhala ndi gawo limodzi lazinthu zolimba komanso gawo limodzi lazinthu zosinthika. Chosanjikiza chokhazikika chimapereka kukhazikika kofunikira ndi chithandizo, pomwe wosanjikiza wosinthika umalola PCB kusinthasintha ndi kupindika. Kukonzekera kumeneku ndi koyenera kwa mapulogalamu omwe amafunikira kusinthasintha kochepa komanso kamangidwe kosavuta.

2 zigawo zokhazikika komanso zofewa:

Mu kasinthidwe uku, PCB imakhala ndi zigawo ziwiri - wosanjikiza wokhazikika ndi wosanjikiza wosinthika. Chosanjikiza chokhazikika chimayikidwa pakati pa zigawo ziwiri zosinthika, ndikupanga dongosolo la "buku". Kukonzekera kumeneku kumapereka kusinthasintha kwakukulu ndikulola mapangidwe ovuta kwambiri pogwiritsa ntchito zigawo mbali zonse za PCB. Amapereka kusinthasintha kwabwinoko pakupindika ndi kupindika kuposa kasinthidwe kagawo limodzi.

Mipikisano wosanjikiza wokhazikika komanso wofewa wapamwamba:

Pakusintha uku, PCB imakhala ndi zigawo zingapo - kuphatikiza zolimba komanso zosinthika. Zigawozo zimayikidwa pamwamba pa wina ndi mzake, kusinthasintha pakati pa zolimba ndi zosinthika. Kukonzekera uku kumapereka kusinthasintha kwapamwamba kwambiri ndipo kumalola mapangidwe ovuta kwambiri pogwiritsa ntchito zigawo zingapo ndi maulendo. Ndizoyenera kugwiritsa ntchito zomwe zimafuna kusinthasintha kwakukulu komanso kapangidwe kake.

Kusankha kosinthika kosunthika kosunthika kumatengera zinthu monga kuchuluka kwa kusinthasintha komwe kumafunikira, zovuta zamapangidwe a dera, ndi zovuta za malo. Mainjiniya amayenera kuwunika mosamala zomwe pulogalamuyo ikufuna komanso zolepheretsa kuti adziwe masanjidwe oyenera kwambiri.

Kuphatikiza pa zomangamanga zolimba-flex laminate, zinthu zina monga kusankha zinthu, makulidwe a gawo lililonse, komanso kudzera ndi mapangidwe olumikizana nawo amathandizanso kwambiri pakuzindikira magwiridwe antchito onse ndi kudalirika kwa ma PCB okhazikika. Ndikofunikira kugwirira ntchito limodzi ndi opanga PCB ndi akatswiri opanga mapangidwe kuti muwonetsetse kuti masinthidwe osankhidwa a stackup akukwaniritsa zofunikira ndi miyezo ya pulogalamuyo.

Posankha masinthidwe oyenera okhazikika okhazikika komanso kukhathamiritsa magawo ena apangidwe, mainjiniya amatha kugwiritsa ntchito ma PCB odalirika, ochita bwino kwambiri omwe amakwaniritsa zosowa zapadera za mapulogalamu awo.

5.Zomwe Muyenera Kuziganizira Posankha Kukonzekera Kokhazikika kwa PCB ya Rigid-Flex

Posankha masinthidwe okhazikika a PCB, pali zinthu zingapo zomwe muyenera kuziganizira kuti muwonetsetse kuti mukuchita bwino komanso kudalirika. Nazi mfundo zisanu zofunika kuzikumbukira:

Signal Integrity:

Kusankhidwa kwa masinthidwe a stackup kumatha kukhudza kwambiri kukhulupirika kwa ma PCB. Kutsata kwa siginecha pamagawo osinthika kumatha kukhala ndi mawonekedwe osiyanasiyana ofananirako poyerekeza ndi zigawo zolimba. Ndikofunikira kusankha masinthidwe a stackup omwe amachepetsa kutayika kwa ma sign, crosstalk, ndi impedance mismatch. Njira zowongolera zowongolera ziyenera kugwiritsidwa ntchito kusunga kukhulupirika kwazizindikiro mu PCB yonse.

Zofunikira Zosintha:

Mlingo wa kusinthasintha wofunikira wa PCB ndikofunikira kulingalira. Mapulogalamu osiyanasiyana amatha kukhala ndi zofunikira zosiyana zopindika ndi kupindika. Kukonzekera kwa stackup kuyenera kusankhidwa kuti kugwirizane ndi kusinthasintha kofunikira ndikuwonetsetsa kuti PCB ikukwaniritsa zofunikira zonse zamakina ndi zamagetsi. Chiwerengero ndi makonzedwe a zigawo zosinthika ziyenera kutsimikiziridwa mosamalitsa potengera zosowa zenizeni za kagwiritsidwe ntchito.

Zolepheretsa Malo:

Malo omwe akupezeka mkati mwa chinthu kapena chipangizo amatha kukhudza kwambiri kusankha masanjidwe a stack-up. Mapangidwe ang'onoang'ono okhala ndi malo ochepa a PCB angafunike masanjidwe amitundu ingapo kuti apititse patsogolo kugwiritsa ntchito malo. Kumbali ina, mapangidwe akuluakulu amalola kusinthasintha posankha masinthidwe a stack-up. Kukonzanitsa ma stacking kuti agwirizane ndi malo omwe alipo popanda kusokoneza magwiridwe antchito kapena kudalirika ndikofunikira.

Kasamalidwe ka Kutentha:

Kuwongolera bwino kwamafuta ndikofunikira kuti tipewe kutentha, zomwe zingakhudze magwiridwe antchito ndi kudalirika kwa mabwalo ndi zigawo. Kusankhidwa kwa masinthidwe a stackup kuyenera kuganiziridwa ndi kutayika kwa kutentha. Mwachitsanzo, ngati PCB imapanga kutentha kwambiri, ingafunike kuyikapo komwe kumathandizira kuchotsa kutentha, monga kuphatikiza zitsulo zachitsulo kapena kugwiritsa ntchito matenthedwe. Zigawo zowotchera ziyeneranso kuikidwa mwadongosolo kuti zithetse kutentha bwino.

Malingaliro a Kupanga ndi Kumanga:

Mapangidwe a stack-up osankhidwa ayenera kukhala osavuta kupanga ndi kusonkhanitsa. Zinthu monga kuphweka kwa kupanga, kugwirizana ndi njira zopangira ndi matekinoloje a msonkhano, ndi kupezeka kwa zipangizo zoyenera ziyenera kuganiziridwa. Mwachitsanzo, masinthidwe ena owunjika angafunike njira zapadera zopangira kapena kukhala ndi malire pazinthu zomwe zingagwiritsidwe ntchito. Kugwira ntchito ndi wopanga PCB koyambirira pamapangidwe ndikofunikira kuti muwonetsetse kuti masinthidwe osankhidwa atha kupangidwa ndikusonkhanitsidwa bwino.

Powunika mosamala zinthu zisanu izi, mainjiniya amatha kupanga chiganizo chodziwika bwino posankha masinthidwe okhazikika a PCB. Ndikofunikira kwambiri kugwira ntchito ndi katswiri wopanga ndi kusonkhana kuti awonetsetse kuti kasinthidwe kosankhidwa kumakwaniritsa zofunikira zonse zamapangidwe ndipo ikugwirizana ndi kupanga. Kupanga mwamakonda ma stackup kuti athetse kukhulupirika kwa ma siginecha, kusinthasintha, zopinga za malo, kasamalidwe ka kutentha ndi malingaliro opanga kumabweretsa yankho lolimba komanso lodalirika la PCB.

6.Design kuganizira zokhazikika-zosinthika PCB stack-up

Popanga zosunga zokhazikika za PCB, pali zinthu zingapo zofunika kuziganizira kuti zitsimikizire kuti zikugwira ntchito moyenera komanso kudalirika. Nazi malingaliro asanu ofunikira pamapangidwe:

Kugawa kwa Layer ndi Symmetry:

Kugawa kwamagulu mu stackup ndikofunikira kuti mukwaniritse bwino komanso kufananiza pamapangidwe. Izi zimathandizira kuti pakhale zovuta kapena zovuta za kugundana panthawi yopindika. Ndibwino kuti mukhale ndi chiwerengero chofanana cha zigawo kumbali iliyonse ya flex board ndikuyika flex layer pakati pa stack. Izi zimatsimikizira kugawa bwino kwa nkhawa ndikuchepetsa chiopsezo cha kulephera.

Kapangidwe ka Cable ndi Trace:

Kapangidwe ka zingwe ndi mayendedwe pa PCB ziyenera kuganiziridwa bwino. Kayendetsedwe ka zingwe ndi njira ziyenera kukonzedwa kuti muchepetse kupsinjika ndikupewa kuwonongeka pakupindika. Ndibwino kuti muyendetse zingwe zosinthika kwambiri komanso zolowera kutali ndi malo omwe ali ndi kupsinjika kwakukulu, monga pafupi ndi mapindikidwe kapena pindani. Kuphatikiza apo, kugwiritsa ntchito ngodya zozungulira m'malo mwa ngodya zakuthwa kumatha kuchepetsa kupsinjika ndikuwongolera kusinthasintha kwa PCB.

Mapulani Apansi ndi Mphamvu:

Kugawa ndege zapansi ndi mphamvu ndizofunikira kwambiri kuti zisungidwe zolondola za chizindikiro ndi kugawa mphamvu. Ndi bwino kugawa odzipereka pansi ndi ndege mphamvu kupereka moyenera ndi khola mphamvu kugawa mu PCB lonse. Zigawozi zimagwiranso ntchito ngati zishango za electromagnetic interference (EMI). Kuyika koyenera kwa ma vias ndi ma vias osokedwa ndikofunikira kuti muchepetse kutsekeka kwapansi ndikuwongolera magwiridwe antchito a EMI.

Kusanthula kwa chizindikiro:

Kukhulupirika kwa siginecha ndikofunikira pakugwira bwino ntchito kwa PCB. Kutsata ma siginecha kuyenera kupangidwa mosamala kuti muchepetse kutha kwa ma impedance, crosstalk, ndi mawonetsedwe azizindikiro. Opanga PCB azigwiritsa ntchito zida zamapulogalamu kuti azisanthula kukhulupirika kwa ma sign kuti akwaniritse m'lifupi mwake ndi malo, kukhalabe ndi vuto lowongolera, ndikuwonetsetsa kukhulupirika kwa ma siginecha pa PCB yonse yokhazikika.

Malo Osinthika ndi Opindika:

Magawo osinthika komanso okhwima a PCB ali ndi zofunikira zosiyanasiyana potengera kusinthasintha komanso kupindika. Ndikofunikira kufotokozera ndikusankha madera enieni a magawo osinthika komanso okhwima. Malo osinthika ayenera kukhala osinthika mokwanira kuti athe kutengera utali wopendekera wofunikira popanda kutsindika zowunikira kapena zigawo zake. Njira zolimbikitsira monga nthiti kapena zokutira za polima zingagwiritsidwe ntchito kuonjezera mphamvu zamakina ndi kudalirika kwa malo osinthika.

Poganizira za mapangidwe awa, mainjiniya amatha kupanga ma stackups okhazikika a PCB. Ndikofunikira kuti mugwire ntchito ndi opanga PCB kuti mumvetsetse zomwe angathe, zomwe angasankhe, komanso zomwe angakwanitse kupanga. Kuphatikiza apo, kuphatikiza gulu lopanga koyambirira pakupanga mapangidwe kumatha kuthandizira kuthetsa zovuta zilizonse zopanga ndikuwonetsetsa kuti kusinthaku kumayenda bwino kuchokera pakupanga kupita kukupanga. Poyang'anitsitsa kugawa kosanjikiza, njira ndi kufufuza malo, ndege zapansi ndi mphamvu, kukhulupirika kwa zizindikiro ndi malo osinthasintha, okonza amatha kupanga ma PCB odalirika komanso ogwira ntchito molimbika.

7.Layer kapangidwe luso kwa okhwima kusintha pcb

Popanga ma board olimba-flex, njira zopangira masanjidwe zimakhala ndi gawo lofunikira pakuwonetsetsa kuti magwiridwe antchito ndi odalirika. Nazi njira zinayi zazikulu zopangira masanjidwe:

Sequential lamination:

Sequential lamination ndi ukadaulo womwe umagwiritsidwa ntchito kwambiri popanga ma board-flex board. Mwa njira iyi, zigawo zosiyana zolimba ndi zosinthika zimapangidwira padera ndiyeno zimadulidwa pamodzi. Zigawo zolimba zimapangidwa pogwiritsa ntchito FR4 kapena zida zofananira, pomwe zigawo zosinthika zimapangidwa pogwiritsa ntchito polyimide kapena magawo osinthika ofanana. Sequential lamination imapereka kusinthasintha kwakukulu pakusankha kosanjikiza ndi makulidwe, kulola kuwongolera kwakukulu pamagetsi ndi makina a PCB. Dual Access Lamination:

Mu wapawiri mwayi lamination, vias ndi mokhomerera mu zigawo okhwima ndi kusintha kulola kupeza mbali zonse za PCB. Tekinoloje iyi imapereka kusinthasintha kwakukulu pakuyika kwazinthu ndikutsata njira. Imathandizanso kugwiritsa ntchito ma vias akhungu ndi okwiriridwa, omwe amathandizira kuchepetsa kuwerengera kosanjikiza ndikuwongolera kukhulupirika kwa chizindikiro. Kuyika panjira ziwiri kumakhala kothandiza kwambiri popanga ma PCB ovuta kusinthasintha okhala ndi zigawo zingapo komanso zopinga zapakati.

Z-axis conductive zomatira:

Z-axis conductive zomatira zimagwiritsidwa ntchito kukhazikitsa kulumikizana kwamagetsi pakati pa wosanjikiza wokhazikika ndi wosanjikiza wosinthika mu bolodi lokhazikika. Amagwiritsidwa ntchito pakati pa ma conductive pads pa flexible layer ndi mapepala ofanana pazitsulo zolimba. Zomatirazo zimakhala ndi tinthu tating'onoting'ono tomwe timapanga njira zoyendetsera zikakanikizidwa pakati pa zigawo panthawi ya lamination. Z-axis conductive zomatira zimapereka kulumikizana kodalirika kwamagetsi kwinaku akusunga kusinthasintha kwa PCB komanso kukhulupirika kwamakina.

Kukonzekera kwa Hybrid stacking:

Pamakonzedwe a hybrid stacking, kuphatikiza kwa zigawo zolimba komanso zosinthika zimagwiritsidwa ntchito kupanga makonda osanjikiza. Izi zimathandiza okonza kukhathamiritsa PCB masanjidwe kutengera zofunikira za kapangidwe. Mwachitsanzo, zigawo zolimba zingagwiritsidwe ntchito kukweza zigawo ndikupereka makina okhwima, pamene zigawo zosinthika zingagwiritsidwe ntchito poyendetsa zizindikiro m'madera omwe kusinthasintha kumafunika. Masanjidwe a ma hybrid stacking amapatsa opanga kusinthasintha kwakukulu komanso makonda a mapangidwe ovuta a PCB.

Pogwiritsa ntchito njira zopangira zosanjikiza izi, opanga amatha kupanga ma PCB olimba omwe ali olimba komanso ogwira ntchito. Komabe, ndikofunikira kugwirira ntchito limodzi ndi wopanga PCB kuonetsetsa kuti ukadaulo wosankhidwa umagwirizana ndi kuthekera kwawo kopanga. Kuyankhulana pakati pa magulu opanga ndi kupanga ndikofunika kwambiri kuti athetse mavuto aliwonse omwe angakhalepo ndikuwonetsetsa kuti kusintha kwabwino kuchoka pakupanga kupita kukupanga. Ndi njira zopangira zosanjikiza zoyenera, opanga amatha kukwaniritsa magwiridwe antchito amagetsi, kusinthasintha kwamakina komanso kudalirika kwa ma PCB okhwima.

8.Rigid-flexible PCB lamination luso kupita patsogolo

Kupita patsogolo kwaukadaulo wokhazikika wa PCB lamination wapita patsogolo kwambiri m'magawo osiyanasiyana. Nazi mbali zinayi za kupita patsogolo kodziwika:

Kusintha Kwazinthu:

Kupita patsogolo kwa sayansi yazinthu kwathandizira kupanga zinthu zatsopano zapansi panthaka zopangidwira ma board okhazikika. Zidazi zimapereka kusinthasintha kwakukulu, kukhazikika, komanso kukana kutentha ndi chinyezi. Pazigawo zosinthika, zinthu monga polyimide ndi liquid crystal polima (LCP) zimapereka kusinthasintha kwabwino posunga magetsi. Kwa zigawo zolimba, zipangizo monga FR4 ndi laminates zotentha kwambiri zimatha kupereka kukhazikika koyenera ndi kudalirika. Zozungulira zosindikizidwa za 3D:

Ukadaulo wosindikiza wa 3D wasintha mafakitale ambiri, kuphatikiza kupanga PCB. Kuthekera kwa 3D kusindikiza zotsatsira molunjika pazigawo zosinthika zimalola mapangidwe ovuta komanso ovuta a PCB. Tekinolojeyi imathandizira kupanga ma prototyping mwachangu komanso makonda, kulola opanga kupanga mawonekedwe apadera ndikuphatikiza zigawo mwachindunji mumagulu osinthika. Kugwiritsa ntchito mabwalo osindikizidwa a 3D mu ma PCB okhazikika kumawonjezera kusinthasintha kwa mapangidwe ndikufupikitsa kayendedwe kachitukuko.

Flexible Embedded Components:

Kupita patsogolo kwina kwakukulu kwaukadaulo wa lamination ndiko kuphatikiza kwachindunji kwa zigawo mu gawo losinthika la PCB yokhazikika. Poika zinthu monga resistors, capacitors ngakhale ma microcontrollers mu magawo osinthika, opanga amatha kuchepetsa kukula kwa PCB ndikuwongolera kukhulupirika kwa ma siginecha. Tekinoloje iyi imathandizira mapangidwe ang'onoang'ono komanso opepuka, ndikupangitsa kuti ikhale yabwino kwa ogwiritsa ntchito omwe ali ndi zopinga zapakati.

Wiring yothamanga kwambiri:

Pomwe kufunikira kwa kulumikizana kothamanga kwambiri kukupitilira kukula, kupita patsogolo kwaukadaulo waukadaulo wa lamination kumathandizira kuti ma waya amawu othamanga kwambiri mu PCBs okhazikika. Gwiritsani ntchito njira zotsogola monga njira zowongolera, njira zosiyanitsira, ndi mapangidwe a microstrip kapena mizere kuti musunge kukhulupirika kwa chizindikiro ndikuchepetsa kutayika kwa ma sign. Zolinga zamapangidwe zimaganiziranso zotsatira za kugwirizana, crosstalk, ndi kuwonetsera ma signal. Kugwiritsa ntchito zida zapadera ndi njira zopangira zimathandizira kukwaniritsa magwiridwe antchito othamanga kwambiri a PCB.

Kupita patsogolo kwaukadaulo wa rigid-flex lamination kukupangitsa kuti pakhale zida zamagetsi zowoneka bwino, zosinthika komanso zowoneka bwino. Kupita patsogolo kwazinthu zatsopano, mabwalo osindikizidwa a 3D, zida zokhazikika zokhazikika komanso njira zamakina othamanga kwambiri zimapatsa opanga kusinthasintha kwakukulu komanso mwayi wopanga mapangidwe apamwamba komanso odalirika a PCB. Pamene ukadaulo ukupitilirabe kusinthika, opanga ndi opanga akuyenera kukhala osinthika ndikugwira ntchito limodzi kuti atengere mwayi pazitukuko zaposachedwa ndikukwaniritsa magwiridwe antchito okhazikika a PCB.

Powombetsa mkota,kupanga ndi kusankha koyenera kokhazikika kokhazikika kwa PCB ndikofunikira kuti mukwaniritse magwiridwe antchito, kudalirika, ndi kusinthasintha. Poganizira zinthu monga kukhulupirika kwa ma siginecha, zofunikira zosinthika ndi zopinga zopanga, opanga amatha kukonza zosungirako kuti zikwaniritse zosowa zawo zenizeni. Kupita patsogolo kopitilira muyeso kwaukadaulo wazinthu kumapereka chiyembekezo chokulirapo cha kapangidwe kamagetsi kamakono. Zida zatsopano zopangira ma PCB okhwima zimasintha kusinthasintha, kulimba, komanso kutentha komanso kukana chinyezi. Kuphatikiza apo, kuphatikiza zigawo mwachindunji mu flex layer kumachepetsanso kukula ndi kulemera kwa PCB, ndikupangitsa kuti ikhale yoyenera kugwiritsidwa ntchito ndi zopinga zapakati. Kuphatikiza apo, kupita patsogolo kwaukadaulo wa lamination kumapereka mwayi wosangalatsa. Kugwiritsa ntchito ukadaulo wosindikiza wa 3D kumatha kupangitsa kuti pakhale zovuta kupanga komanso kuwongolera ma prototyping mwachangu komanso makonda.

Kuphatikiza apo, kupita patsogolo kwaukadaulo wowongolera ma siginecha othamanga kwambiri kumathandizira ma PCB okhazikika kuti akwaniritse kulumikizana koyenera komanso kodalirika.

Pamene ukadaulo ukupitilirabe kusinthika, opanga amayenera kudziwa zomwe zapita patsogolo komanso kugwirira ntchito limodzi ndi opanga. Potengera kupita patsogolo kwa zida ndi matekinoloje opangira, opanga amatha kupanga mapangidwe apamwamba komanso odalirika a PCB kuti akwaniritse zosowa zamakampani omwe amasintha nthawi zonse. Ndi lonjezo la mapangidwe apamwamba a zamagetsi, tsogolo la ma PCB osasunthika osasunthika likuwoneka bwino.

Nthawi yotumiza: Sep-12-2023

Kubwerera