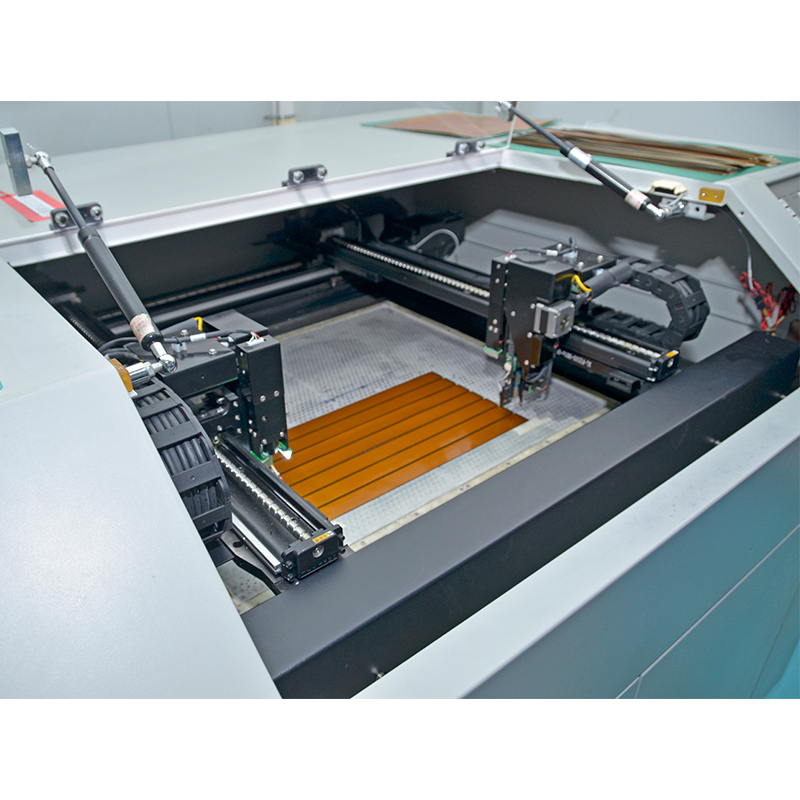

Ukadaulo wa msonkhano wa PCB umagwira ntchito yofunika kwambiri popanga ndi kusonkhanitsa matabwa ozungulira.Ukadaulo uwu umatsimikizira kupanga bwino, kwapamwamba komanso kopanda ndalama zama board ozungulira a prototype.Mu positi iyi yabulogu, tiwona njira zina zofananira za PCB. Tisanalowe mwatsatanetsatane, tiyeni titchule mwachidule Capel, kampani yomwe ili ndi zaka 15 mumakampani oyendetsa dera, yokhala ndi gulu laukadaulo, luso laukadaulo laukadaulo wotsogola, komanso fakitale yake yopanga ndi msonkhano.

Capel wakhala mtsogoleri pamakampani opanga ma boardboard kwa zaka zopitilira 15, wodzipereka kukwaniritsa zosowa zosiyanasiyana za makasitomala ake.Kampaniyo ili ndi gulu la akatswiri odziwa zambiri omwe apeza luso lamtengo wapatali pakupanga ndi kusonkhana kwa matabwa a dera. Ukadaulo wotsogola wotsogola wa Capel umatsimikizira miyezo yapamwamba kwambiri komanso njira zopangira zopangira.

Kukhala ndi makina ake opanga ma boardboard ndi malo ochitira misonkhano kumapatsa Capel mwayi wampikisano.Kukonzekera uku kumapangitsa kampani kuwongolera bwino ntchito yopanga, kuwonetsetsa kutumizidwa munthawi yake ndikusunga kuwongolera kwabwino kwambiri. Kuphatikiza apo, ukatswiri wa kampaniyo pakupanga ndi kusonkhana kwa PCB kumathandizira kuti ipatse makasitomala mayankho athunthu komanso otsika mtengo.

Tsopano popeza tikudziwa bwino Capel ndi kuthekera kwake, tiyeni tifufuze njira zolumikizirana za PCB zomwe zimagwiritsidwa ntchito kwambiri

makampani.

1. Ukadaulo wa Surface Mount (SMT):

Ukadaulo wa Surface Mount (SMT) ndi imodzi mwamaukadaulo omwe amagwiritsidwa ntchito kwambiri pa PCB. Zimakhudza kukwera zigawo molunjika pamwamba pa PCB. SMT imapereka maubwino angapo, kuphatikiza kuthekera kokhala ndi tinthu tating'onoting'ono, kachulukidwe kagawo kakang'ono, komanso magwiridwe antchito amagetsi.

2. Ukadaulo wapabowo (THT):

Kupyolera muzitsulo zamakono (THT) ndi luso lakale la msonkhano lomwe limaphatikizapo kukwera kwa zigawo poyika zitsulo m'mabowo mu PCB ndikuzigulitsa mbali inayo. THT imagwiritsidwa ntchito pazinthu zomwe zimafuna mphamvu zowonjezera zamakina kapena zazikulu kwambiri kwa SMT.

3. Kuyang'ana modzidzimutsa (AOI):

Automated optical inspection (AOI) ndiukadaulo womwe umagwiritsidwa ntchito powunika ma PCB omwe alumikizidwa kuti apeze zolakwika kapena zolakwika. Makina a AOI amagwiritsa ntchito makamera ndi ma aligorivimu ozindikira zithunzi kuti ayang'ane mbali zosiyanasiyana za PCB, monga kuyika kwa zigawo, ma solder joints, ndi polarity. Ukadaulo uwu umatsimikizira msonkhano wapamwamba kwambiri komanso umachepetsa mwayi wazinthu zosalongosoka zofikira makasitomala.

4. Kuwunika kwa X-ray:

Kuwunika kwa X-ray ndiukadaulo wosawononga wowunika womwe umagwiritsidwa ntchito poyang'ana ma PCB pazinthu zobisika, monga zolumikizira zogulitsira kapena zinthu zosadzaza pansi pazigawo. Kuwunika kwa X-ray kumathandizira kuzindikira zolakwika monga kusakwanira kwa solder, zolumikizira zoziziritsa kukhosi, kapena ma voids omwe sangawonekere pakuwunika kowonekera.

5. Kukonzanso ndi kukonza:

Kukonzanso ndi kukonza njira ndizofunikira kukonza zolakwika kapena kusintha zida zolakwika pa PCB zomwe zasonkhanitsidwa. Amisiri aluso ntchito zida zapaderazi ndi zipangizo desolder ndi m'malo zigawo zikuluzikulu popanda kuwononga PCB. Njirazi zimachepetsa zinyalala ndi kupulumutsa matabwa opanda pake, kupulumutsa nthawi ndi chuma.

6. Kuwotcherera kosankha:

Selective soldering ndi njira yomwe imagwiritsidwa ntchito kugulitsa zida zapabowo pa PCB popanda kukhudza zida zokwera pamwamba. Zimapereka kulondola kwakukulu ndikuchepetsa mwayi wowononga zigawo zapafupi.

7. Mayeso a pa intaneti (ICT):

In-circuit test (ICT) imagwiritsa ntchito zida zoyesera zapadera kuti ziwone momwe zigawo zadera zimagwirira ntchito pa PCB. Zimathandizira kuzindikira zida zolakwika, mabwalo otseguka kapena achidule kapena magawo olakwika. ICT imapereka mayankho ofunikira kuti apititse patsogolo mapangidwe ndi kusonkhanitsa.

Izi ndi zina mwa njira zomwe zimagwiritsidwa ntchito ndi makampani ngati Capel. Kukula kosalekeza kwaukadaulo kumalola opanga kufufuza njira zatsopano ndikuwongolera pagulu la msonkhano wadera.

Zomwe Capel wachita komanso ukadaulo wake pamakampani opanga ma boardboard, kuphatikiza ukadaulo wake wapamwamba wa PCB wapagulu, zimapangitsa kuti ikhale mnzake wodalirika kwa makasitomala ake.Kudzipereka kwa kampaniyo popereka ntchito zogwira ntchito bwino, zapamwamba komanso zotsika mtengo zopangira ma board board ndi misonkhano yama msonkhano zimaziyika pamsika.

Powombetsa mkota, kumvetsetsa njira wamba PCB prototyping msonkhano n'kofunika kwa onse opanga ndi makasitomala.Makampani monga Capel amawonjezera luso lawo, luso lawo, ndi luso lamakono kuti apereke njira zopangira ma boardboard ndi misonkhano. Posankha bwenzi lodalirika monga Capel, makasitomala amapindula ndi njira zogwirira ntchito, kuwongolera khalidwe lapamwamba komanso njira zothetsera ndalama.

Nthawi yotumiza: Oct-19-2023

Kubwerera