Flexible printed circuit boards (PCBs), omwe amadziwikanso kuti flex PCBs, adziwika kwambiri m'zaka zaposachedwa chifukwa cha luso lawo lopindika komanso kupindika. Ma board osinthika awa ndi osinthika kwambiri ndipo amapeza ntchito m'mafakitale ambiri, kuphatikiza zamagalimoto, zamagetsi ogula, chisamaliro chaumoyo, ndi matelefoni. Mukayitanitsa ma PCB osinthika, ndikofunikira kumvetsetsa zomwe zimakhudza mitengo yawo kuti akwaniritse zotsika mtengo komanso zogwira mtima.M'nkhaniyi, tifufuza zinthu zazikulu zomwe zimakhudza kusinthasintha kwa mawu a PCB, kukuthandizani kupanga zisankho mwanzeru poika maoda. Podziwa pazifukwa izi, mutha kukhathamiritsa bajeti yanu ndikuwonetsetsa kuti zofunikira zanu za PCB zikugwirizana ndi zosowa zanu zenizeni ndi miyezo yamakampani.

1.Design Complexity: Chimodzi mwazinthu zazikulu zomwe zimakhudza mawu osinthika a PCB ndizovuta kupanga.

Kuvuta kwa mapangidwe kumachita gawo lofunikira pakuzindikira mtengo wopanga ma flex PCB. Mapangidwe ovuta nthawi zambiri amakhala ozungulira movutikira, magwiridwe antchito apamwamba, ndi zofunikira zapadera zomwe zimafunikira zida ndi njira zapadera. Zofunikira zowonjezera izi zimakulitsa nthawi yopangira ndi kuyesetsa, zomwe zimapangitsa kuti pakhale ndalama zopangira zokwera.

Chimodzi mwazinthu zovuta kupanga ndikugwiritsa ntchito zida zomveka bwino. Zigawo zowoneka bwino zimakhala ndi milingo yocheperako, yomwe imafunikira kulondola kwambiri popanga. Izi zimafuna zida zapadera ndi njira zowonetsetsa kuti zikuyenerana. Masitepe owonjezera ndi kusamala kofunikira pazigawo zomveka bwino zimawonjezera zovuta kupanga komanso mtengo.

Ma radii ang'onoang'ono a bend ndi chinthu china chomwe chimakhudza zovuta zamapangidwe. Ma board osinthika osindikizidwa amadziwika kuti amatha kupindika ndi kupindika, koma ma bend radii akachepa kwambiri, izi zimapangitsa kuti pakhale zopinga pakupanga. Kukwaniritsa ma radii ang'onoang'ono kumafuna kusankha mosamala zinthu ndi njira zopindika zolondola kuti mupewe kuwonongeka kwa dera kapena kupunduka. Zowonjezera izi zimawonjezera zovuta zopangira komanso mtengo.

Kuonjezera apo, njira zowonongeka zowonongeka ndi mbali ina yomwe imakhudza zovuta za mapangidwe. Mapangidwe apamwamba nthawi zambiri amafunikira njira zovuta, kugawa mphamvu, ndi ndege zapansi. Kupeza njira yolondola mu ma flex PCBs kungakhale kovuta ndipo kungafunike njira zowonjezera monga njira zapadera zopangira mkuwa kapena kugwiritsa ntchito njira zakhungu ndi zokwiriridwa. Zofunikira zowonjezera izi zimakulitsa zovuta zopangira komanso mtengo.

2.Kusankha kwazinthu:Chinthu china chofunikira pakuzindikira mawu osinthika a PCB ndikusankha kwazinthu.

Kusankha zinthu ndizofunikira kwambiri pakuzindikira mtengo wa PCB wosinthika. Magawo osiyanasiyana amapereka magawo osiyanasiyana a magwiridwe antchito komanso mtengo wake. Kusankha kwazinthu kumadalira zofunikira za ntchito.

Polyimide (PI) imadziwika ndi magwiridwe ake apamwamba, kuphatikiza kukhazikika kwamafuta komanso kusinthasintha. Ikhoza kupirira kutentha kwakukulu ndipo ndi yoyenera kwa mapulogalamu omwe ali ndi kutentha kwapamwamba kwambiri. Komabe, kuchita bwino kwambiri kwa polyimide kumabwera pamtengo wokwera poyerekeza ndi zida zina. Izi ndichifukwa chazovuta komanso zotsika mtengo zopangira zida za polyimide.

Polyester (PET) ndi gawo lina lodziwika bwino la ma PCB osinthika. Ndi yotsika mtengo kuposa polyimide ndipo imakhala yabwino kusinthasintha. Ma polyester-based flex PCBs ndi oyenera kugwiritsa ntchito omwe ali ndi zofunikira zochepa za kutentha. Komabe, kukhazikika kwamafuta a polyester sikwabwino ngati kwa polyimide, ndipo magwiridwe ake onse amatha kukhala ochepa. Kwa mapulogalamu otsika mtengo omwe ali ndi zovuta zogwirira ntchito, ma polyesters ndi chisankho chotheka komanso chotsika mtengo.

PEEK (polyetheretherketone) ndi chinthu chogwira ntchito kwambiri chomwe chimagwiritsidwa ntchito movutikira. Ili ndi zida zabwino kwambiri zamakina komanso kutentha ndipo ndi yoyenera pazovuta kwambiri. Komabe, PEEK ndiyokwera mtengo kwambiri kuposa polyimide ndi polyester. Nthawi zambiri amasankhidwa kuti agwiritse ntchito pomwe ntchito yapamwamba ikufunika ndipo mtengo wapamwamba wazinthu ukhoza kulungamitsidwa.

Kuphatikiza pa zinthu zapansi panthaka, zinthu zina zomwe zimagwiritsidwa ntchito popanga, monga laminates, mafilimu ophimba ndi zomatira, zimakhudzanso mtengo wonse. Mtengo wa zipangizo zowonjezerazi ukhoza kusiyana malinga ndi khalidwe lawo ndi machitidwe awo. Mwachitsanzo, ma laminate apamwamba kwambiri okhala ndi zida zamagetsi zamagetsi kapena makanema apadera okhala ndi chitetezo chokhazikika kuzinthu zachilengedwe atha kuwonjezera pamtengo wonse wa PCB yosinthika.

3.Kuchuluka ndi chithunzithunzi: Kuchuluka kwa PCB yosinthika yofunikira kumachita gawo lofunikira pakuzindikira mawuwo.

Kuchuluka kofunikira ndi chinthu chachikulu pamene mitengo ya PCB imasinthasintha. Opanga nthawi zambiri amayesa mitengo yotengera kuchuluka kwake, zomwe zikutanthauza kuti kuchuluka kwake kumapangitsa kuti mtengo wake ukhale wotsika. Izi zili choncho chifukwa madongosolo okulirapo amalola kuti pakhale chuma chabwinoko ndikuchepetsa mtengo wopangira

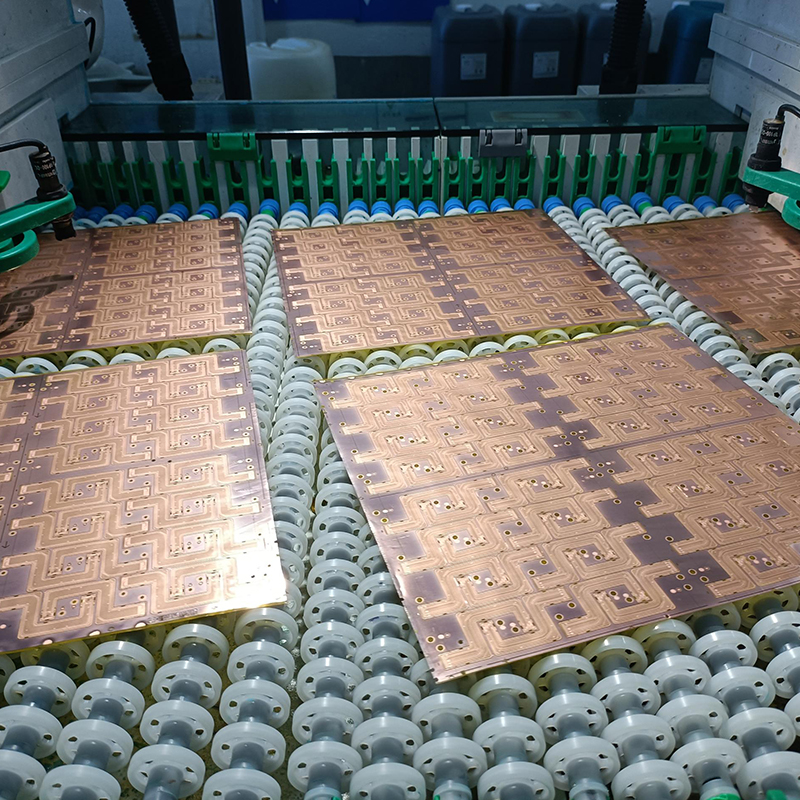

Njira ina yokwaniritsira kugwiritsiridwa ntchito kwa zinthu ndi kupanga bwino ndi panelization. Panelization imaphatikizapo kuphatikiza ma PCB ang'onoang'ono angapo kukhala gulu lalikulu. Pokonzekera mwaluso mapangidwe pamapanelo, opanga amatha kuchepetsa zinyalala ndikukulitsa zokolola panthawi yopanga.

Panelization ili ndi maubwino angapo. Choyamba, zimachepetsa zinyalala zakuthupi pogwiritsa ntchito bwino kwambiri malo omwe amapezeka pagulu. M'malo mopanga ma PCB osiyana okhala ndi malire awo ndi malo awoawo, opanga amatha kuyika mapangidwe angapo pagulu limodzi, kupindula kwambiri ndi malo osagwiritsidwa ntchito pakati. Izi zimabweretsa kupulumutsa kwakukulu kwa zinthu ndi kutsika mtengo.

Kuphatikiza apo, panelization imathandizira kupanga zinthu mosavuta. Imathandiza kupanga zinthu zodziwikiratu komanso zogwira mtima chifukwa ma PCB angapo amatha kusinthidwa nthawi imodzi. Izi zimawonjezera zokolola ndikuchepetsa nthawi yopangira, zomwe zimapangitsa kuti nthawi yotsogolera ikhale yocheperako komanso mtengo wotsika. Kukonzekera koyenera kumafuna kukonzekera bwino ndikuganizira zinthu monga kukula kwa PCB, zofunikira za mapangidwe, ndi luso lopanga. Opanga atha kugwiritsa ntchito zida zapadera zamapulogalamu kuti zithandizire pakupanga magulu, kuwonetsetsa kuti zikuyenda bwino komanso kugwiritsa ntchito bwino zida.

Kuphatikiza apo, mapangidwe apangidwewo ndi osavuta kunyamula ndi kunyamula. Pambuyo kupanga ndondomeko yatha, mapanelo akhoza kupatulidwa mu PCBs munthu. Izi zimathandizira kulongedza ndikuchepetsa kuwonongeka pakutumiza, zomwe zimapulumutsa ndalama.

4.Surface Finish ndi Copper Weight: Kumapeto kwa pamwamba ndi kulemera kwa mkuwa ndizofunika kwambiri muflexible PCB kupanga ndondomeko.

Kumaliza kwapamwamba ndi gawo lofunikira pakupanga kwa PCB chifukwa kumakhudza mwachindunji kugulitsa komanso kulimba kwa bolodi. Chithandizo chapamwamba chimapanga chotchinga choteteza pazitsulo zamkuwa zowonekera, kuteteza okosijeni ndikuwonetsetsa kuti ma solder odalirika amalumikizana. Thandizo lapamwamba losiyanasiyana lili ndi ndalama komanso zopindulitsa zosiyanasiyana.

Kumaliza kofala ndi HASL (Hot Air Solder Leveling), komwe kumaphatikizapo kuyika solder pazitsulo zamkuwa ndikugwiritsanso ntchito mpweya wotentha kuti usakule. HASL ndiyotsika mtengo ndipo imapereka kugulitsa kwabwino, koma sikungakhale koyenera kuwongolera bwino kapena zigawo zomveka bwino chifukwa cha mawonekedwe osagwirizana omwe amapanga.

ENIG (Electroless Nickel Immersion Gold) ndi mankhwala ena omwe amagwiritsidwa ntchito kwambiri pamtunda. Kumaphatikizapo kuika faifi wopyapyala pamwamba pa mkuwa, kenako ndi golide wosanjikiza. Kugulitsa kwabwino kwambiri kwa ENIG, malo athyathyathya, komanso kukana kwa dzimbiri kumapangitsa kuti ikhale yoyenera pazigawo zowoneka bwino komanso mapangidwe apamwamba kwambiri. Komabe, ENIG ili ndi mtengo wokwera poyerekeza ndi mankhwala ena apamtunda.

OSP (Organic Solderability Preservative) ndi mankhwala apamtunda omwe amaphatikizapo kugwiritsa ntchito kagawo kakang'ono ka organic kuti ateteze mikwingwirima yamkuwa. OSP imapereka kugulitsa bwino, kulinganiza komanso kuchita bwino. Komabe, sizolimba monga momwe zimathera zina ndipo zingafunike kuchitidwa mosamala panthawi yosonkhanitsa.

Kulemera (mu ma ounces) amkuwa mu PCB kumatsimikizira momwe bolodi imayendera komanso magwiridwe antchito. Zigawo zokhuthala zamkuwa zimapereka kukana kocheperako ndipo zimatha kuthana ndi mafunde apamwamba, kuwapangitsa kukhala oyenera kugwiritsa ntchito mphamvu. Komabe, zigawo zamkuwa zokulirapo zimafunikira njira zambiri zopangira zida zamakono, potero zimawonjezera mtengo wonse wa PCB. Mosiyana ndi izi, zigawo zamkuwa zowonda kwambiri ndizoyenera kugwiritsa ntchito mphamvu zochepa kapena ntchito pomwe pali zopinga za malo. Amafuna zinthu zochepa komanso zotsika mtengo. Kusankhidwa kwa kulemera kwa mkuwa kumadalira zofunikira zenizeni za mapangidwe a PCB ndi ntchito yake.

5.Technology Yopangandi Mold:Njira zopangira ndi zida zomwe zimagwiritsidwa ntchito popanga ma PCB osinthika zimakhudzanso mitengo.

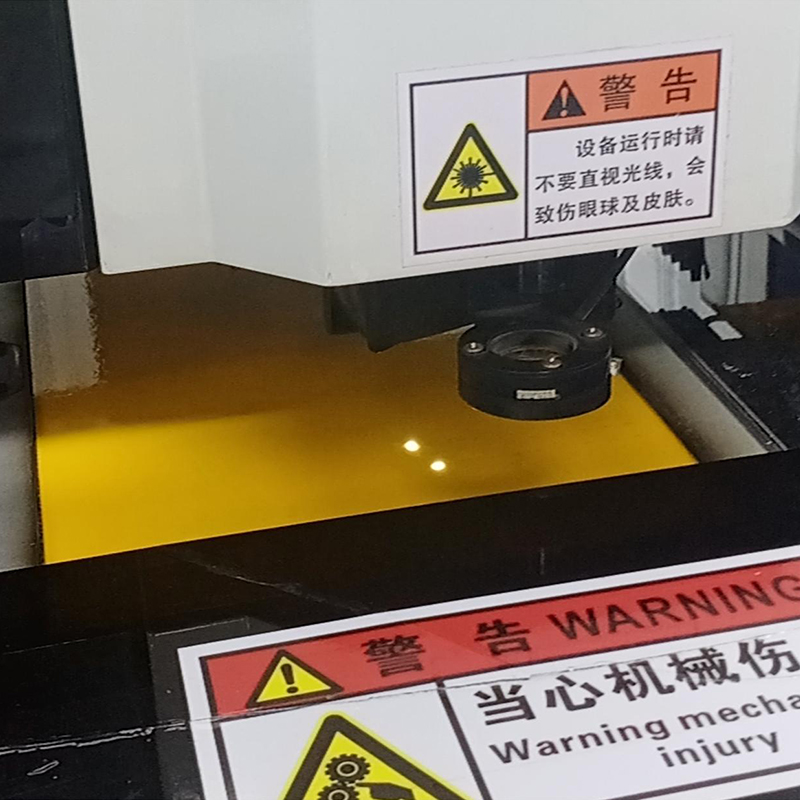

Ukadaulo wopangira zinthu umathandizira kwambiri kupanga ma PCB osinthika ndipo zimakhudza kwambiri mitengo yamitengo. Ukadaulo wapamwamba kwambiri, monga kubowola kwa laser ndi sequential build-up (SBU), ukhoza kupanga mapangidwe ovuta komanso olondola, koma njirazi nthawi zambiri zimabwera ndi mtengo wapamwamba wopanga. Kubowola kwa laser kumatha kupanga ma vias abwino ndi mabowo ang'onoang'ono, kupangitsa mabwalo otalikirana kwambiri mu ma PCB osinthika. Komabe, kugwiritsa ntchito ukadaulo wa laser komanso kulondola komwe kumafunikira pakukonzaku kumawonjezera ndalama zopangira.

Sequential build up (SBU) ndi njira ina yopangira zida zapamwamba zomwe zimaphatikizapo kusanjikiza mabwalo angapo osinthika kuti apange mapangidwe ovuta kwambiri. Ukadaulo uwu umawonjezera kusinthasintha kwa kapangidwe kake ndikupangitsa kuphatikiza ntchito zosiyanasiyana mu PCB imodzi yosinthika. Komabe, zovuta zowonjezera pakupanga zimawonjezera ndalama zopangira.

Kuphatikiza pa njira zopangira, njira zenizeni zomwe zimakhudzidwa popanga ma PCB osinthika zimathanso kukhudza mitengo. Njira monga plating, etching, ndi lamination ndi njira zofunika kwambiri popanga PCB yokhazikika komanso yodalirika. Ubwino wa ntchitozi, kuphatikizapo zipangizo zogwiritsidwa ntchito ndi mlingo wolondola wofunikira, zimakhudza mtengo wonse

Zida zamagetsi ndi zatsopano zimathandizira kukulitsa zokolola komanso kuchita bwino pantchito yopanga. Makina odzichitira okha, makina opangira ma robotiki, ndi makina opangira makompyuta (CAM) amatha kuphweka kupanga, kuchepetsa zolakwika za anthu, ndikufulumizitsa kupanga. Komabe, kugwiritsa ntchito makina oterowo kungawononge ndalama zina, kuphatikiza kuyika ndalama patsogolo pazida ndi kuphunzitsa antchito.

Kuphatikiza apo, kugwiritsa ntchito zida ndi matekinoloje atsopano, monga mapulogalamu apamwamba a PCB ndi zida zowunikira, zitha kuthandiza kukweza mitengo. Zida zimenezi nthawi zambiri zimafuna luso lapadera, kukonza ndi kukonzanso, zomwe zimawonjezera mtengo wonse. Opanga ayenera kuganizira mozama za kulinganiza pakati pa matekinoloje opangira zinthu, njira, zodzipangira okha ndi zida zatsopano kuti akwaniritse mtengo ndi kusanja bwino komwe kumafunikira pakupanga kosinthika kwa PCB. Pofufuza zofunikira zenizeni za polojekiti ndikugwira ntchito ndi makasitomala, opanga amatha kudziwa zamakono ndi njira zoyenera kwambiri pamene akuchepetsa ndalama ndikuwonetsetsa zotsatira zabwino kwambiri zopangira.

6.Nthawi yotumiza ndi kutumiza:Nthawi yotsogolera yofunikira ndi chinthu chofunikira chomwe chikukhudza kusinthasintha kwa mawu a PCB.

Zikafika pa nthawi yosinthika ya PCB, nthawi yotsogolera imakhala ndi gawo lofunikira. Nthawi yotsogolera ndi nthawi yomwe imatenga kuti wopanga amalize kupanga ndikukonzekera kuyitanitsa kutumiza. Nthawi zotsogola zimakhudzidwa ndi zinthu zingapo, kuphatikiza zovuta za kapangidwe kake, kuchuluka kwa ma PCB omwe adalamulidwa, komanso kuchuluka kwa ntchito komwe wopanga akupanga.

Kulamula mopupuluma kapena ndandanda zolimba nthawi zambiri zimafuna opanga kuti aziyika patsogolo kupanga ndikugawa zina zowonjezera kuti akwaniritse nthawi yomaliza. Zikatero, kupanga kungafunikire kufulumizitsa, zomwe zingapangitse kuti mtengo ukhale wokwera. Opanga atha kulipiritsa chindapusa chofulumira kapena kugwiritsa ntchito njira zapadera zowonetsetsa kuti ma PCB osinthika amapangidwa ndikuperekedwa mkati mwa nthawi yomwe yakhazikitsidwa.

Ndalama zotumizira zimakhudzanso mtengo wonse wa flex PCB. Ndalama zotumizira zimatsimikiziridwa ndi zifukwa zingapo. Choyamba, malo otumizira amathandizira kwambiri pamtengo wotumizira. Kutumiza kumadera akutali kapena akutali kungaphatikizepo mtengo wokwera chifukwa cha kuchuluka kwa mtengo wotumizira. Kuonjezera apo, kufulumira kwa kutumiza kudzakhudzanso mtengo wotumizira. Ngati kasitomala akufuna kutumiza mwachangu kapena usiku wonse, mitengo yotumizira idzakhala yokwera poyerekeza ndi njira zotumizira.

Mtengo woyitanitsa umakhudzanso mtengo wotumizira. Opanga ena atha kupereka kutumiza kwaulere kapena kuchotsera pamaoda akulu ngati chilimbikitso kwa makasitomala kuyitanitsa zambiri. Kumbali ina, pamaoda ang'onoang'ono, zolipiritsa zotumizira zitha kukhala zokwera kwambiri kuti zilipire ndalama zomwe zimafunikira pakupakira ndi kusamalira.

Kuti atsimikizire kutumiza bwino komanso kuchepetsa mtengo, opanga amatha kugwirira ntchito limodzi ndi opereka zida kuti adziwe njira yotumizira yotsika mtengo kwambiri. Izi zitha kuphatikizira kusankha chonyamulira choyenera, kukambirana mitengo yabwino yotumizira, ndikuwongolera zolongedza kuti muchepetse kulemera ndi kukula.

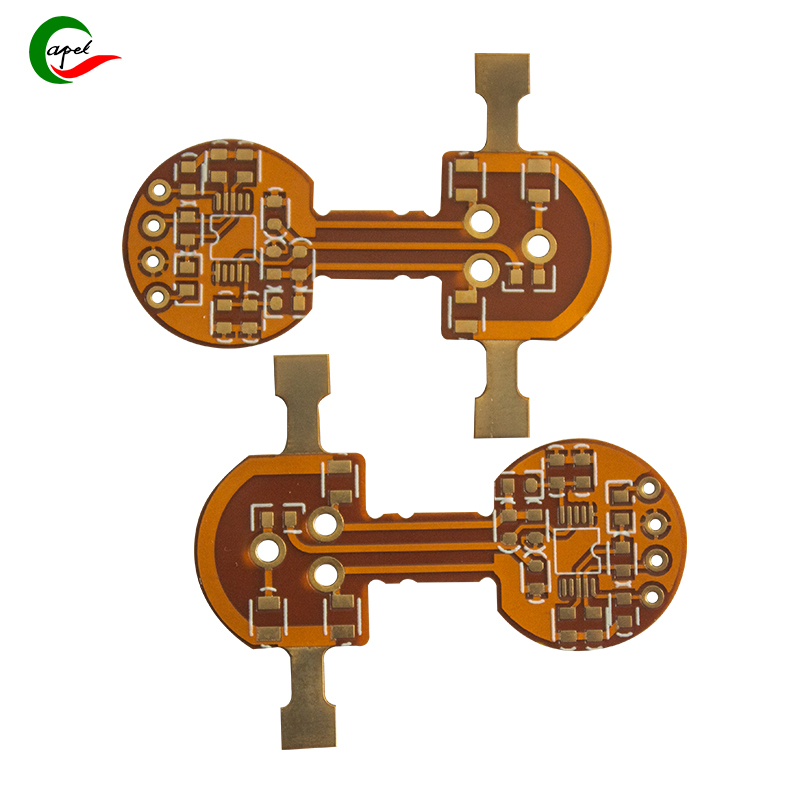

Powombetsa mkota,pali zinthu zambiri zomwe zimakhudza mawu a PCB osinthika. Makasitomala omwe amamvetsetsa bwino izi amatha kupanga zisankho zodziwika bwino ndikuwongolera njira zawo zopangira.Kuvuta kwa mapangidwe, kusankha kwazinthu ndi kuchuluka kwake ndizinthu zazikulu zomwe zimakhudza mtengo wa PCB wosinthika.Kapangidwe kake kakuvuta kwambiri, ndiye kuti mtengo wake ndi wapamwamba kwambiri. Zosankha zakuthupi, monga kusankha gawo laling'ono lapamwamba kwambiri kapena kumaliza pamwamba, zingakhudzenso mtengo. Komanso, kuyitanitsa zokulirapo nthawi zambiri kumabweretsa kuchotsera kwakukulu. Zinthu zina, monga kupanga mapanelo, kulemera kwa mkuwa, njira zopangira ndi zida, zimathandizanso kudziwa mtengo. Paneling imalola kugwiritsa ntchito bwino zinthu komanso kumachepetsa mtengo. Kulemera kwa mkuwa kumakhudza kuchuluka kwa mkuwa wogwiritsidwa ntchito, zomwe zimakhudza mtengo ndi ntchito ya flex PCB. Njira zopangira ndi zida, monga kugwiritsa ntchito ukadaulo wapamwamba kapena zida zapadera, zimatha kukhudza mitengo. Pomaliza, nthawi yotsogolera ndi kutumiza ndizofunikira. Ndalama zowonjezera zitha kugwira ntchito poyitanitsa mwachangu kapena kupanga mwachangu, ndipo mtengo wotumizira umadalira zinthu monga malo, changu, ndi mtengo wa maoda. Powunika mosamala zinthuzi ndikugwira ntchito ndi wopanga PCB wodziwa komanso wodalirika, makampani amatha kusintha PCB yotsika mtengo komanso yapamwamba kwambiri yomwe imakwaniritsa zosowa zawo zenizeni.Shenzhen Capel Technology Co., Ltd. yakhala ikupanga matabwa osinthika osindikizidwa (PCBs) kuyambira 2009.Pakadali pano, timatha kupereka matabwa a 1-30 osanjikiza osinthika osindikizidwa. Ukadaulo wathu wopanga HDI (High Density Interconnect) wosinthika wa PCB ndiwokhwima kwambiri. Pazaka 15 zapitazi, takhala tikupanga luso laukadaulo mosalekeza ndipo tapeza zambiri pakuthana ndi mavuto okhudzana ndi projekiti kwa makasitomala.

Nthawi yotumiza: Aug-31-2023

Kubwerera