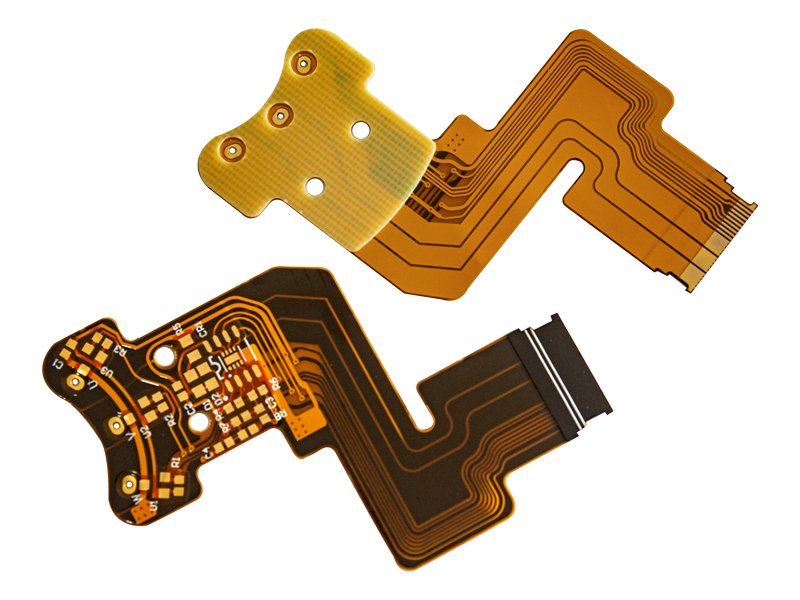

Ma PCB osinthika amagwiritsidwa ntchito m'mafakitale ndi ntchito zosiyanasiyana, kuphatikiza zamagetsi ogula, zamagetsi zamagalimoto, zakuthambo, zida zamankhwala, zolumikizirana ndi zina zambiri. Nthawi zambiri amapezeka muzipangizo monga mafoni a m'manja, mapiritsi, zovala, makina oyendetsa magalimoto, zipangizo zowonetsera zamankhwala ndi zowonetsera zosinthika.

Kuphatikiza pa kusinthasintha, ma PCB osinthika apamwamba ali ndi zabwino zina. Amachepetsa kukula ndi kulemera kwa zida zamagetsi, amathandizira kukhulupirika kwa ma siginecha pochepetsa kutayika kwa ma siginecha ndi kusokonezedwa ndi ma elekitiroma (EMI), kumathandizira kuwongolera matenthedwe pochotsa kutentha bwino, kumathandizira kuphatikiza ndi kuyesa, ndikuwonjezera kulimba ndi kudalirika.

Ponseponse, ma PCB osinthika apamwamba amapereka mayankho pamapangidwe apakompyuta omwe amafunikira kusinthasintha, kupulumutsa malo, komanso magwiridwe antchito odalirika m'malo ovuta. Amapereka maubwino ambiri omwe amawapangitsa kukhala odziwika bwino pamapulogalamu amakono amagetsi.

HDI

Zamakono

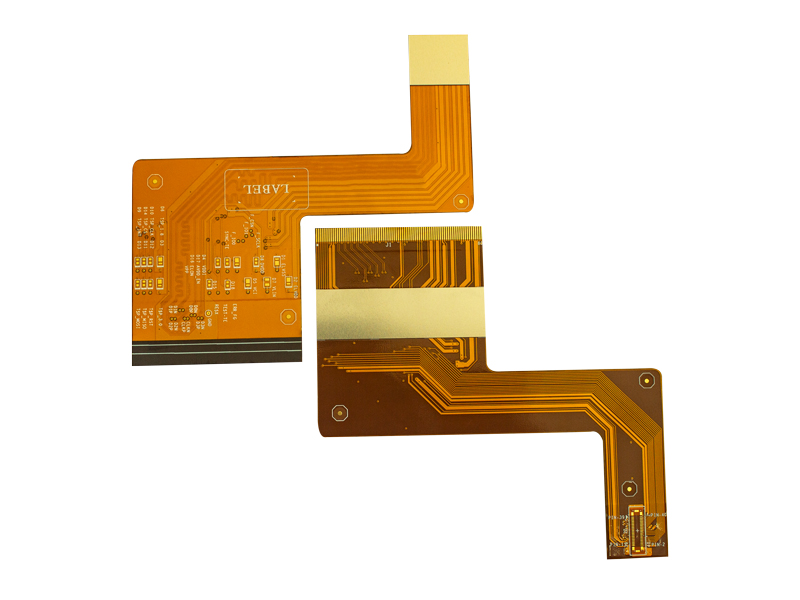

Ukadaulo wa High-Density Interconnect (HDI) utha kugwiritsidwa ntchito ku ma PCB osinthika, kulola kuwongolera pang'ono kwa zigawo ndikugwiritsa ntchito kuyika bwino kwambiri. Izi zimathandiza kuti kachulukidwe kozungulira, kuwongolera ma sigino abwino komanso magwiridwe antchito ang'onoang'ono.

Flex-to-Install Technology

Imalola PCB kukhala yopindika kapena kupindika panthawi yopanga, kupangitsa kuti ikhale yosavuta kuyiyika ndikulowa mumipata yothina. Izi ndizothandiza makamaka pamapulogalamu omwe ali ndi malo, monga zida zovalira, masensa a IoT, kapena ma implants azachipatala.

Zigawo Zophatikizidwa

Phatikizani zinthu zophatikizidwa monga resistors, capacitors kapena zida zogwira ntchito mwachindunji mu gawo lapansi losinthika. Kuphatikizikaku kumapulumutsa malo, kumachepetsa kusonkhana, ndikuwongolera kukhulupirika kwa chizindikiro pochepetsa kutalika kwa kulumikizana.

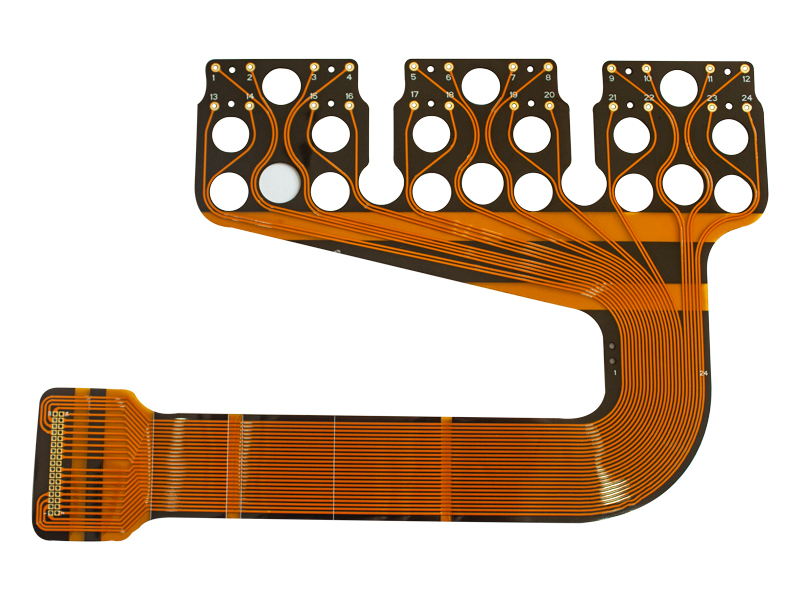

Thermal Management

Kuphatikizidwa ndi ukadaulo wapamwamba wowongolera matenthedwe kuti muzitha kutentha bwino. Izi zitha kuphatikiza kugwiritsa ntchito zida zopangira ma thermally, ma vias otentha, kapena masinki otentha. Kuwongolera koyenera kwamafuta kumatsimikizira kuti zigawo za PCB zimagwira ntchito mkati mwa malire awo a kutentha, kuwongolera kudalirika komanso moyo wonse.

Kukaniza Kwachilengedwe

Kupirira madera ovuta, kuphatikizapo kutentha kwambiri, chinyezi chachikulu, kugwedezeka kapena kukhudzana ndi mankhwala. Izi zimatheka pogwiritsa ntchito zipangizo zapadera ndi zokutira zomwe zimawonjezera kukana zinthu zachilengedwe izi, kupanga ma PCB oyenera kugwiritsira ntchito magalimoto, mafakitale kapena kunja.

Design for Manufacturability

Phunzirani mozama za DFM kuti muwonetsetse kupanga koyenera komanso kotsika mtengo. Izi zikuphatikiza kukhathamiritsa kukula kwa mapanelo, njira zopangira ma panels ndi njira zopangira kuti muchepetse zinyalala, kuwonjezera zokolola komanso kuchepetsa ndalama zonse zopangira.

Kudalirika ndi Kukhalitsa

Kupyolera mu kuyesa mozama ndi ndondomeko yoyendetsera bwino kuti muwonetsetse kudalirika ndi kukhazikika. Izi zikuphatikiza kuyesa magwiridwe antchito amagetsi, kusinthasintha kwamakina, kugulitsa ndi magawo ena kuwonetsetsa kuti ma PCB akukwaniritsa miyezo yamakampani ndi zomwe makasitomala amafuna.

Zokonda Zokonda

Perekani zosankha makonda kuti mukwaniritse zofunikira za pulogalamu, kuphatikiza mawonekedwe, makulidwe, mapangidwe a stackup ndi mawonekedwe apadera kutengera zomwe mukufuna kumapeto.