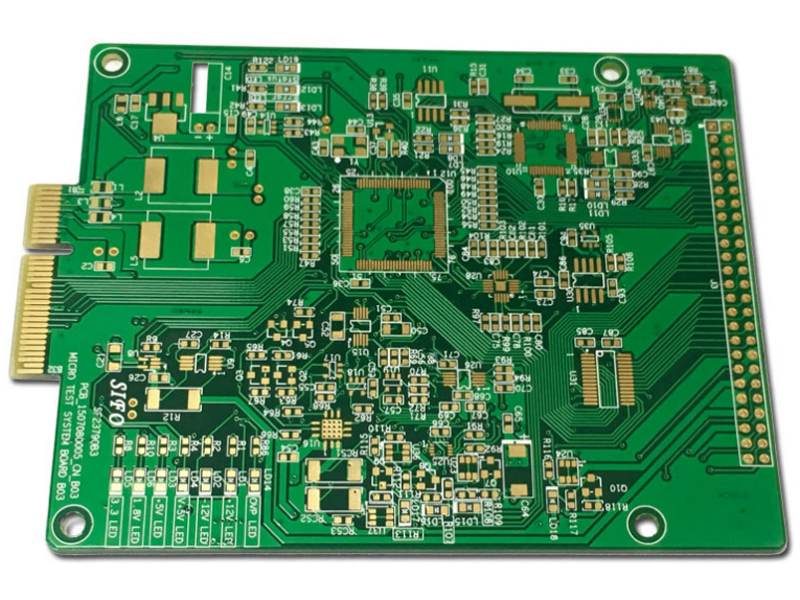

Kodi High-Precision PCBs ndi chiyani

bolodi losindikizidwa bwino kwambiri, lomwe limadziwikanso kuti bolodi losindikizidwa bwino kwambiri,

ndi gawo lamagetsi lomwe limagwiritsidwa ntchito kwambiri pamapulogalamu omwe amafunikira mabwalo olondola komanso olondola.

Ma PCB awa adapangidwa ndikupangidwa ndi chidwi chachikulu mwatsatanetsatane, kuonetsetsa kuti ali olondola kwambiri komanso odalirika.

Ma PCB olondola kwambiri amagwiritsidwa ntchito m'mafakitale monga zakuthambo, zida zamankhwala, zolumikizirana ndi matelefoni, ndi magalimoto. Ndiwofunika makamaka pamapulogalamu omwe amafunikira kukhulupirika kwa ma siginecha, magwiridwe antchito apamwamba, kulolerana kolimba, komanso kuphatikiza kwaukadaulo wapamwamba.

PCBs awa amapangidwa ntchito njira zapamwamba ndi njira monga ankalamulira impedance mawaya, zigawo zabwino phula, vias yaying'ono, vias akhungu ndi m'manda, ndi interconnects mkulu kachulukidwe. Angaphatikizeponso zigawo zingapo, mabwalo ovuta komanso zida zapadera kuti zikwaniritse zofunikira zomwe mukufuna kugwiritsa ntchito.

Njira yopangira ma PCB olondola kwambiri imaphatikizapo njira zoyendetsera bwino kwambiri, kuphatikiza kuyesa mozama ndikuwunika, kuonetsetsa kuti chomaliza chikukwaniritsa zofunikira. Kulondola ndi kulondola kumeneku kumapangitsa kuti pakhale ntchito yabwino komanso yodalirika, makamaka muzinthu zovuta zamagetsi.

CAPEL High-Precision PCBs

Ma PCB olondola kwambiri adapangidwa kuti azilumikizana ndi magetsi odalirika komanso olondola. Amakhala ndi njira zosiyanasiyana zopangira akatswiri ndikutsata njira zoyeserera komanso zoyeserera kuti akwaniritse zofunikira zomwe zimafunikira m'mafakitale osiyanasiyana.

Zida Zapamwamba

Ma PCB olondola kwambiri nthawi zambiri amapangidwa pogwiritsa ntchito zida zapamwamba, monga ma laminates othamanga kwambiri kapena zoumba zapamwamba. Zidazi zili ndi zinthu zina zomwe zimathandizira kukonza magwiridwe antchito amagetsi a PCB ndi kukhulupirika kwa ma siginecha.

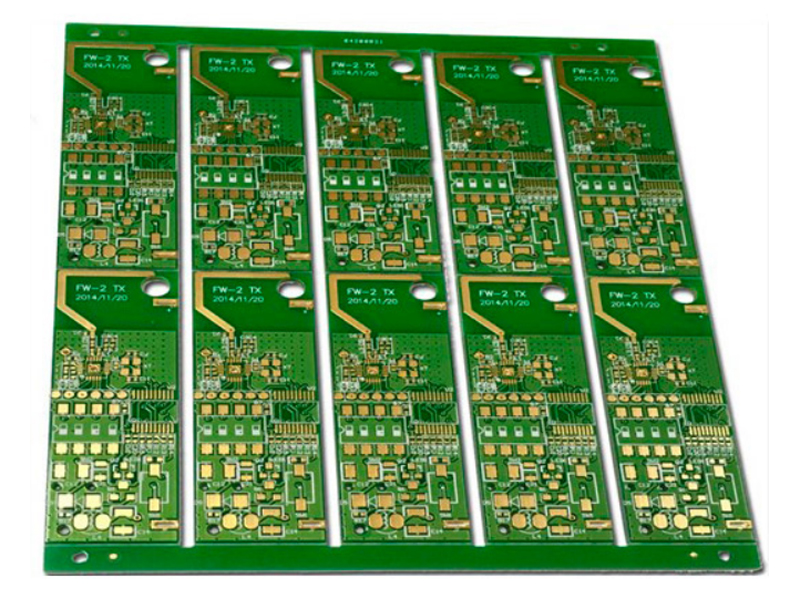

Mapangidwe Amitundu Yambiri

Ma PCB olondola kwambiri nthawi zambiri amakhala ndi magawo angapo, zomwe zimapangitsa kuti pakhale mawonekedwe ovuta komanso owoneka bwino. Kumanga kwamitundu ingapo kumathandizira kukonza kudzipatula kwa ma signal, kuchepetsa crosstalk ndi kukhathamiritsa kugawa mphamvu.

Fine Line ndi Space

Ma PCB olondola kwambiri nthawi zambiri amafuna mzere wabwino kwambiri komanso kutalika kwa danga, nthawi zambiri amayezedwa ndi ma microns. Njira zopapatizazi zimalola kuti ziziyenda bwino komanso zichepetse kutayika kwa ma sign kapena kusokoneza.

Kulepheretsa Kulamulira

Kuwongolera kwa impedance ndikofunikira kuti musunge kukhulupirika kwazizindikiro pamapulogalamu othamanga kwambiri. PCB yolondola imayang'anira kutsekeka kwa njira yonse kuti ifanane ndi mawonekedwe omwe amafunidwa ndi kapangidwe kake.

Advanced Technology

Ma PCB olondola kwambiri nthawi zambiri amagwiritsa ntchito umisiri wotsogola wopangira monga kubowola laser komanso kujambula molunjika. Kubowola kwa laser kumathandizira kuti zing'onozing'ono, zolondola kwambiri kudzera m'miyeso, pomwe kujambula mwachindunji kumathandizira kulembetsa chigoba cha solder.

Kuyesa ndi Kuyang'anira

Kuwongolera kwabwino ndikofunikira pama PCB olondola kwambiri. Njira zoyesera mozama ndi zowunikira monga automated optical inspection (AOI) ndi X-ray inspection zimagwiritsidwa ntchito kuti zizindikire zolakwika kapena zovuta zilizonse zomwe zingachitike ndikuwonetsetsa kuti PCB ikukwaniritsa zofunikira.

Design for Manufacturability

Ma PCB olondola kwambiri amafunikira malingaliro athunthu a DFM panthawi yopangira kuti zitsimikizire kuti mapangidwe amatha kupangidwa bwino komanso molondola. Njira za DFM zimathandizira kukhathamiritsa kapangidwe kazinthu zopangira ndikuwonjezera zokolola zonse.

Zida za Miniaturized

Ma PCB olondola kwambiri nthawi zambiri amapangidwa kuti azikhala ndi zida zazing'ono monga zida zapamtunda za microelectromechanical systems (MEMS). Kuyika bwino ndi kugulitsa zigawo zing'onozing'onozi zimathandiza kuti PCB ikhale yolondola komanso yogwira ntchito.